Table of Contents

Lithium Mining

Lithium is becoming popular as a viable alternative to the fossil fuel-based economy. However, when we think of mining or extraction, we immediately think of fossil fuels such as coal and gas. Despite paving the way for an electric future, lithium, unfortunately, falls under the same umbrella. Lithium is a non-renewable mineral that enables storing renewable energy, and it is frequently referred to as the “next oil.” This adaptable element is used in various electronic devices, including mobile phones, laptops, aircraft, and electric cars. When you consider that a single Tesla Model S requires a substantial 12 kg of Lithium metal in its battery pack alone, the significance of lithium becomes evident.

The lithium-ion battery’s dominance stems from its exceptional qualities, which include lightweight design, rechargeable capacity, and high energy density. As a result, researchers face significant challenges in developing alternative battery chemistry that incorporates all of these desirable properties. As a result, extensive global research efforts are underway, with the consensus being that lithium-based chemistry will continue to be the most acceptable and practical solution for the foreseeable future. And not one of these advantages can be obtained for free.

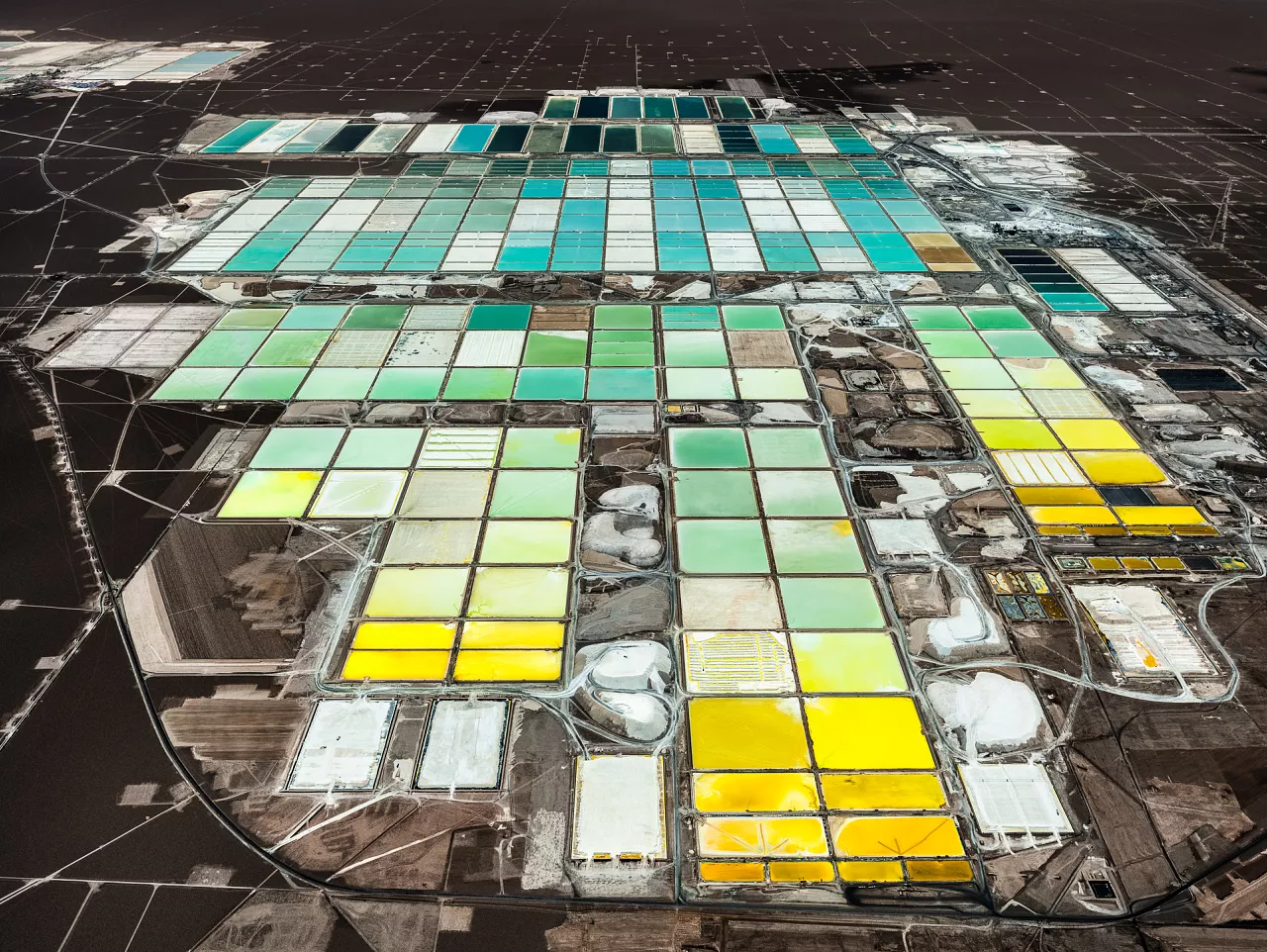

This necessitates extensive mining of Li metal, which has a negative impact on the environment by degrading soil and causing and harming local ecosystems. Below is Tom Hegen’s photograph of Lithium Fields in the Salar de Atacama salt flats in northern Chile.

Why Lithium is in High Demand?

- Lithium is a critical component of high-energy-density batteries. As the world transitions to a more sustainable energy future, the demand for lithium-ion batteries is expected to grow significantly.

- Lithium supply is critical from a strategic standpoint. The majority of the world’s lithium reserves are concentrated in a few countries: Chile, Australia, Argentina, and China. This means a few countries wield considerable power over the global lithium supply.

- The Earth’s crust contains about 0.002 % lithium, which is more abundant than copper, zinc, and lead.

- Lithium-ion batteries are relatively environmentally friendly. They do not contain toxic heavy metals like lead or cadmium, and they are recyclable.

- The EU has set a goal of requiring all new cars and vans to be zero-emission by 2035.

- The US is looking to phase out all fossil fuel-reliant heavy-duty vehicles by 2040.

- As of 2021, the global demand for lithium was about 317,517 metric tonnes. Industry estimates project that demand for lithium will be up to six times greater by 2030.

What are the Leading Lithium Reserve Countries?

| Country | World Lithium Reserve (%) | Amount (Metric Tonn x 105) | Percent of Conversion From ore to mineral (%) |

| Chile | 35.30 | 93 | 38.20 |

| Australia | 14.60 | 38 | 35.70 |

| Argentina | 10.70 | 27 | 27.30 |

| China | 8.40 | 20 | 20.80 |

| Bolivia | 6.10 | 15 | 15.80 |

| Other | 4.90 | 12 | 12.20 |

How Does Battery-Grade Lithium Extraction Work?

The production of battery-grade lithium involves several processes that aim to purify the lithium to meet the stringent quality requirements for battery applications. The production of battery-grade lithium typically involves the following steps:

1. Mining

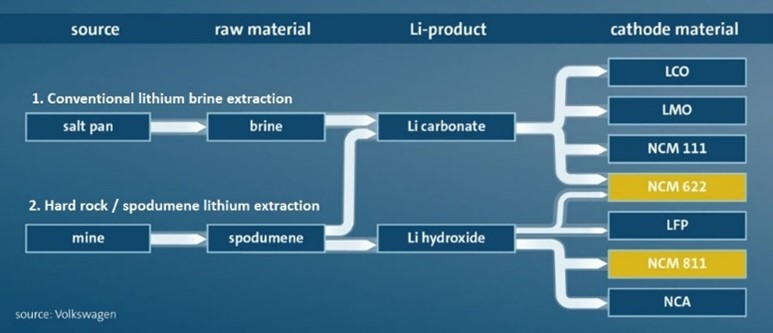

Lithium can be mined from hard rock ores or brines. Hard rock ores are typically processed using a method called spodumene beneficiation, which involves crushing and leaching the ore to extract the lithium. Brines are processed using a technique called evaporation, which consists in concentrating the brine until the lithium can be extracted.

2. Purification

The lithium extracted from hard rock ores or brines is typically impure and needs to be purified before it can be used in batteries. The purification process typically involves precipitation, filtration, and crystallisation.

3. Conversion

Purified lithium can be converted into different forms, such as lithium carbonate or hydroxide. These forms are used in the production of lithium-ion batteries.

Some of the Extraction Techniques

#1. Conventional lithium brine extraction

Lithium is mainly extracted from brine reservoirs beneath salt flats, known as salars. The most productive salars are located in South America and China. Other lithium-rich brine resources include geothermal and oil field brines. Lithium brine recovery is a lengthy process that can take several months to a few years. The brine is pumped to the surface and distributed to evaporation ponds exposed to solar evaporation. The brine remains in the ponds for months or years until most water evaporates. The remaining brine is then pumped to a lithium recovery facility for extraction.

The extraction process typically involves the following steps:

- Pretreatment: The brine is filtered and/or treated with ion exchange resins to remove impurities.

- Chemical treatment: The brine is treated with chemical solvents and reagents to precipitate out unwanted elements.

- Filtration: The brine is filtered to remove the precipitated solids.

- Saleable lithium production: The brine is treated with a reagent to produce a desired form of lithium, such as lithium carbonate, lithium hydroxide, lithium chloride, lithium bromide, or butyl lithium.

- Return to the reservoir: The remaining brine solution is returned to the underground reservoir.

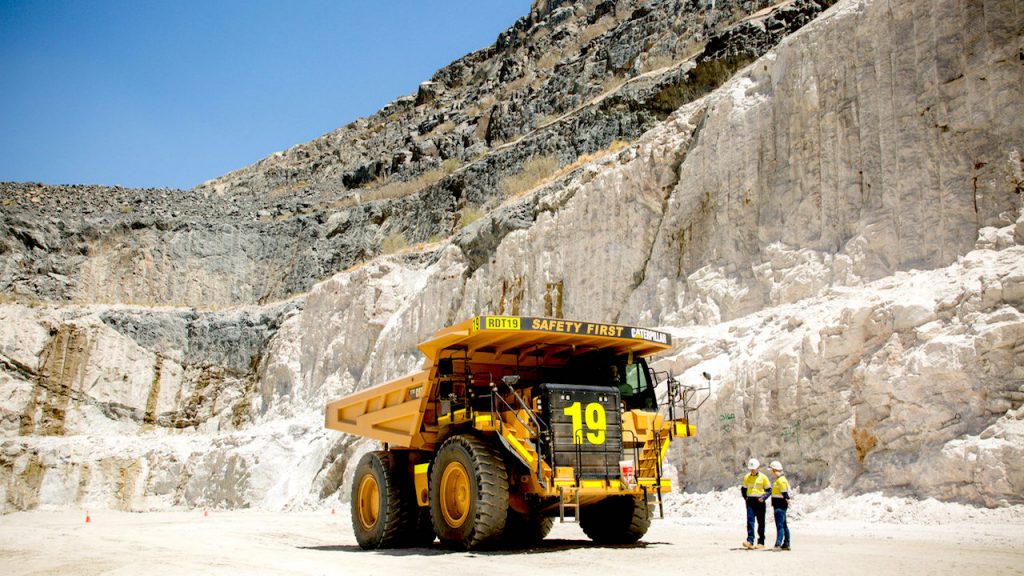

#2. Hard Rock/spodumene Lithium Extraction

Hard rock lithium extraction is a relatively small but growing segment of the lithium industry. The most common mineral extracted from lithium is spodumene, found in hard rock formations. Extracting lithium from hard rock is more energy-intensive and costly than from brines, but it can produce higher-purity lithium.

The process of extracting lithium from hard rock typically involves the following steps:

- Mining: The mineral material is removed from the earth.

- Crushing and pulverising: The mineral material is crushed and pulverised into a fine powder.

- Chemical reaction: The crushed mineral powder is combined with chemical reactants like sulfuric acid.

- Heating: The slurry is heated to facilitate the chemical reaction.

- Filtering: The slurry is filtered to remove impurities.

- Evaporation: The concentrated slurry is evaporated to form saleable lithium carbonate.

- Treatment of wastewater: The wastewater is treated for reuse or disposal.

#3. Direct Lithium Extraction (DLE)

Absorption from saline water sources to an ion exchange material or bead, followed by washing with hydrochloric acid, producing dilute lithium chloride with impurities. DLE tends to fit lithium resources with higher hardness in areas unsuitable for evaporation ponds.

#4. Hectorite Clay

Hectorite clay is a potential source of lithium, but the extraction process is not yet economically viable. Several techniques have been developed, including acid, alkaline, chloride, and sulphate leaching, water disaggregation and hydrothermal treatment. However, these techniques have yet to produce lithium at a competitive cost with other sources.

#5. Seawater

Seawater is another potential source of lithium. It is estimated that hundreds of billions of tons of lithium are in the oceans. Existing processes for extracting lithium from seawater include co-precipitation extraction and a hybrid IX-sorption process. However, these processes still need to be economically viable.

The Prospects for Lithium Mining in India

India is working to establish a domestic lithium supply chain and is actively exploring its lithium reserves to meet the growing demand for lithium-ion batteries. Lithium mining in India is conducted primarily to extract spodumene and lepidolite, two minerals containing lithium. These materials are abundant in the pegmatite deposits of the Indian states of Jharkhand, Rajasthan, and Andhra Pradesh.

The current lithium reserves in India are estimated to be around 49,000 metric tonnes. Unfortunately, the country’s vast lithium reserves have not been thoroughly investigated and estimated. The Indian government has been actively promoting the exploration and development of lithium mining projects through policy initiatives and incentives.

As the country works to lessen its reliance on lithium imports and establish a self-sustaining lithium supply chain, India’s outlook for lithium extraction is positive. The development of domestic lithium resources is a government priority, as evidenced by the National Mineral Policy and the Faster Adoption and Manufacturing of Electric Vehicles (FAME) programme.

As part of its “Aatmanirbhar Bharat” (Self-Reliant India) campaign, the Indian government has highlighted lithium as a critical mineral, highlighting the importance of homegrown production and value addition in the lithium industry. Efforts are being made to improve lithium extraction techniques by attracting foreign investments, boosting R&D efforts, and encouraging partnerships between industry and academia.

| State | Location | Quantity (Tonnes) | Ore type |

| Rajasthan | Jalore, Barmer, Jodhpur, and Bikaner | 1,400,000 | Spodumene |

| Andhra Pradesh | Kadapa | 50,000 | Spodumene |

| Telangana | Nalgonda | 30,000 | Spodumene |

| Gujarat | Banaskantha | 20,000 | Spodumene |

Challenges and Risks of Lithium Mining for the Environment

#1. Pollutes Water Sources

Lithium minerals contain dangerous substances that contaminate the local water basins, exposing the ecosystem to a poisonous and unhealthy situation. And the extraction is from salt brine; it also leads to the salinisation of fresh water.

#2. Carbon dioxide emission

Lithium extraction frequently necessitates large areas of deformation, and it also necessitates the use of heavy machinery to extract lithium from the earth’s crust, which consumes a lot of fossil fuel-based energy and emits many toxic gases. As a result, your electric car may have a net negative impact on carbon emissions. However, metal extraction is carbon-intensive, especially when miners do not use clean energy.

#3. Exploitation of water resources

Due to its extensive water needs, the exploitation of water resources in lithium mining poses significant challenges. Approximately 2,2 million litres of water are required to extract a single tonne of lithium. However, this extraction has adverse effects on other activities in mining regions. In arid and semiarid areas, insufficient water for agriculture, contamination of water bodies, and acute water shortages have become prevalent problems. Thus, these conditions can contribute to the spread of waterborne diseases like dysentery and cholera.

#4. Depletes Fertile Land

Mining necessitates large areas, frequently including fertile land previously used for farming or as forest. These mines are primarily found in hot, dry, mountainous regions, and removing resources from such fertile ecosystems has serious environmental consequences. Furthermore, these areas are home to a wide range of wildlife populations, which significantly impacts their habitats and overall well-being.

#5. Massive Minning Waste

Among the most common mining byproducts are sulfuric acid discharge and radioactive uranium waste. These substances pose significant health risks, potentially leading to various types of cancer and diseases. Furthermore, mining operations generate significant amounts of lime and magnesium waste, contributing to environmental concerns.

Authors Conclusion

Are the lithium extraction processes environmentally friendly? They do not. Surprisingly, demand for lithium batteries has increased since 2018. The prediction of 125 million EVs by 2030 is likely to come true, implying that the need for lithium batteries will continue to rise. That means lithium mining isn’t going away anytime soon; plus, it helps us store the renewable energy we generate. So, what are we to do? To begin, we should invest in lithium-ion battery alternatives. At the same time, recycling and extending the life of these batteries would reduce the need to mine vast quantities of precious material, as would efforts to develop sustainable and responsible mining practises with minimal impact on the environment and communities in that area, as well as investing in advanced mining methods capable of extracting lithium from seawater.

Read More:- Top Lithium-ion battery Gigafactory in India