The evolution of electric vehicles (EVs) has started a new era of transportation, offering a promising solution to environmental concerns, and reducing reliance on fossil fuels. EVs’ battery systems are central to their operation, as they store and provide the energy required for propulsion. Lithium-ion batteries (LIBs) have emerged as the most widely adopted and commercialized battery type in EVs due to their high energy density, long cycle life, and relatively low self-discharge rates. However, in recent years, there has been an increase in concern about the safety of LIBs, with numerous incidents of battery fires and thermal runaway events reported in both consumer electronics and electric vehicles. These incidents highlight the critical need for extensive research and development efforts to improve battery safety and reliability in pursuit of a sustainable and secure electrified transportation future.

Some Fire incidents

In 2022, lithium-ion batteries were linked to a minimum of 220 fires in New York City, as reported by city statistics. Additionally, they were identified as the cause of at least 10 fatalities and 226 injuries during the years 2021 and 2022.

In September 2022, Hyderabad witnessed a major tragedy as a fire erupted in an electric bike showroom located in the basement of a multi-story building. The incident resulted in the loss of eight lives as the fire extended to a hotel situated on the higher floors. Another tragic incident occurred in the same year in the Vasai area of Palghar, Maharashtra, where a seven-year-old boy passed away while undergoing treatment for injuries sustained in a blast caused by an electric scooter battery. A comprehensive research perspective on the secure storage of automotive high-voltage storage systems, comprising multiple lithium-ion battery packs, is currently lacking. This gives rise to inquiries regarding fire spread dynamics, potential uncontrolled propagation, and extensive fire scenarios during the production and storage of high-voltage storage units.

Fire experimental segment of large-scale fire tests should involve concurrently assessing up to 16 high-voltage storage units. Guidelines for storing lithium-ion high-voltage batteries should be formulated to prevent large-scale fires through effective, cost-efficient, and practical fire protection solutions.

A Tesla Model S electric vehicle caught fire when debris struck the battery pack while the car was on the highway, leading to cells short-circuiting and entering a state of thermal runaway.

What Causes Li-ion Batteries Fire?

The potential fire hazards associated with lithium-ion batteries stem from their high energy densities and the presence of flammable organic electrolytes. This poses challenges in terms of usage, storage, and handling. The heightened energy density of lithium batteries makes them more prone to reactions under certain conditions. Research indicates that factors such as physical damage, electrical abuse (such as short circuits and overcharging), and exposure to elevated temperatures can trigger a thermal runaway. This phenomenon involves rapid self-heating resulting from an exothermic chemical reaction during cell failure, leading to a chain reaction thermal runaway in neighboring cells, releasing additional heat.

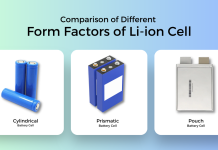

Manufacturer defects, like imperfections or contaminants in the manufacturing process, can also contribute to thermal runaway. This reaction vaporizes the organic electrolyte and pressurizes the cell casing. In case of a casing failure, flammable and toxic gases are released from within the cell. The severity of a runaway battery reaction is linked to the accumulation and release of pressure inside the cell. Cells designed with pressure release mechanisms, such as pressure relief vents or soft cases, generally exhibit less severe reactions compared to cells that contain pressure and rupture due to high pressure, such as unvented cylindrical cells. Thus, the cell construction significantly influences the severity of a battery incident. The severity of the reaction depends on various parameters, including battery size, chemistry, construction, and the battery state of charge (SOC).

In almost all significant battery reactions, similar hazardous components are produced, including flammable by-products (such as aerosols, vapors, and liquids), toxic gases, and flying debris, some of which may be burning. In most burning scenarios, the electrolyte burns efficiently, primarily producing carbon dioxide (CO2) and water (H2O) as by-products. For many batteries, the products usually consist of CO2 and water vapor. The burning reaction may also release fluorine from the lithium salt (typically LiPF6) dissolved in the electrolyte, which reacts with hydrogen to form hydrogen fluoride (HF). HF production is proportional to the electrical energy stored in the cell/battery and can result in dangerous concentrations. HF reacts with the water vapor produced during the reaction and/or with the mucous membranes in the human body (i.e., eyes, nose, throat, lungs), forming hydrofluoric acid.

Addressing Issue of Thermal Runaway Management

Researchers are actively pursuing the creation of cathodes with reduced oxygen release during breakdown, nonflammable electrolytes, solid-state electrolytes that are resistant to combustion and may aid in minimizing dendrite growth, and separators capable of withstanding elevated temperatures without melting. Scientists are relentlessly scrutinizing the fire behavior of cell chemistry individually through experimental testing in each production facility for lithium-ion battery cells, leading to a tailored risk evaluation and fire protection plan.

Battery Management System

These encompass both hardware and software components integrated into battery packs, responsible for monitoring crucial battery parameters, including the state of charge, internal pressure, and cell temperatures within the battery pack. Due to the swift evolution of battery chemistries, the development of new designs will necessitate updated battery management systems. Numerous battery manufacturers are engaging in partnerships that unite expertise from complementary battery specialists to address this challenge.

What Consumers Can Do

Hereby, it is always advisable to follow manufacturer’s instructions for storage, use, charging, and maintenance. These more or less include replacing batteries and chargers for an electronic device, ensure they are specifically designed and approved for use with the device and they are purchased from the device’s manufacturer or a manufacturer authorized reseller.

Lithium-powered devices and batteries from the charger must be removed once they are fully charged, and stored lithium batteries/devices in dry, cool locations. Inspect them for signs of damage, such as bulging/cracking, hissing, leaking, rising temperature, and smoking before use, especially if they are wearable. Immediately remove a device or battery from service and place it in an area away from flammable materials if any of these signs are present.

Conclusion

Finally, the growing concerns about the fire hazards associated with lithium-ion batteries (LIBs) highlight the critical need for extensive research and proactive safety measures in the fields of electric vehicles (EVs) and consumer electronics. With the rapid adoption of EVs and the widespread use of LIBs, thermal runaway and battery fires have become more common, posing serious threats to public safety and infrastructure. The incidents in New York City, Hyderabad, and Vasai serve as stark reminders of the risks associated with LIBs, emphasizing the critical need for improved safety protocols and regulatory measures. To address these challenges, researchers are diligently investigating various avenues. Additionally, collaboration between battery manufacturers and regulatory bodies is required to establish standardized safety guidelines and protocols for the production, storage, and handling of LIBS. Furthermore, consumers play an important role in ensuring the safe use and maintenance of lithium-powered devices by following manufacturer instructions and promptly reporting any signs of battery damage or malfunction. By taking a proactive approach to battery safety and implementing strong mitigation strategies, we can reduce the risks associated with lithium-ion batteries, paving the way for a safer and more sustainable future in electrified transportation and consumer electronics.