Table of Contents

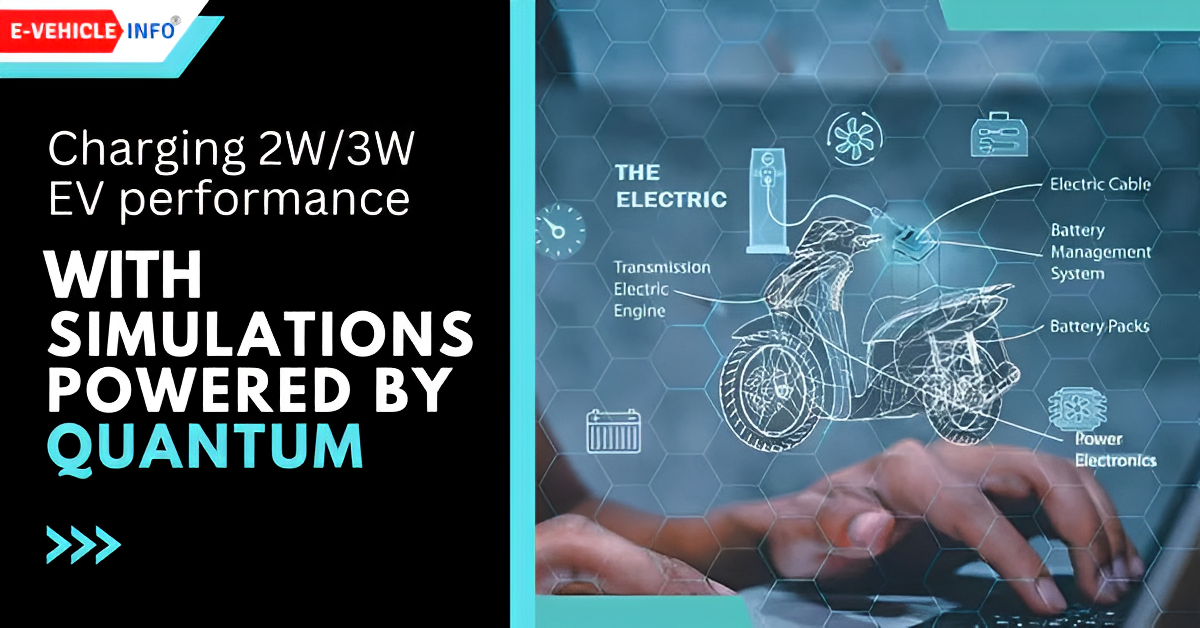

EV Charging with Simulations Powered by Quantum

EVs are predicted to increase from 2 million vehicles in 2022 to more than 23 million by 2030, and the overall EV sales by about six-fold in eight years. However, the electric 2W market is expected to grow faster, with over 80% of the overall 2W market by 2030. The demand has been spurred due to its low-cost affordability at the consumer level – an electric two-wheeler is significantly cheaper per km. Another factor aiding its growth is the rise in e-commerce and delivery-based businesses. The E2W is apt for last-mile connectivity and app-based micro-mobility services in a densely populated country like India.

Simulations powered by Quantum can spur this growth faster through improvements in battery technology. E2/3W manufacturers can accelerate innovations such as new material formulations and battery thermal management systems. However, complex simulations using many variables were bottlenecked due to the limited computational power of classical high-performance computing (HPCs). As a result, engineering teams had to trade-off between high accuracy and time to market.

Simulations powered by Quantum can spur this growth faster through improvements in battery technology. E2/3W manufacturers can accelerate innovations such as new material formulations and battery thermal management systems. However, complex simulations using many variables were bottlenecked due to the limited computational power of classical high-performance computing (HPCs). As a result, engineering teams had to trade-off between high accuracy and time to market.Computation processing with the exponential power of Quantum can overcome this limitation by processing large amounts of data to make simulations faster. Additionally, this allows more engineering simulations with the same computational power.

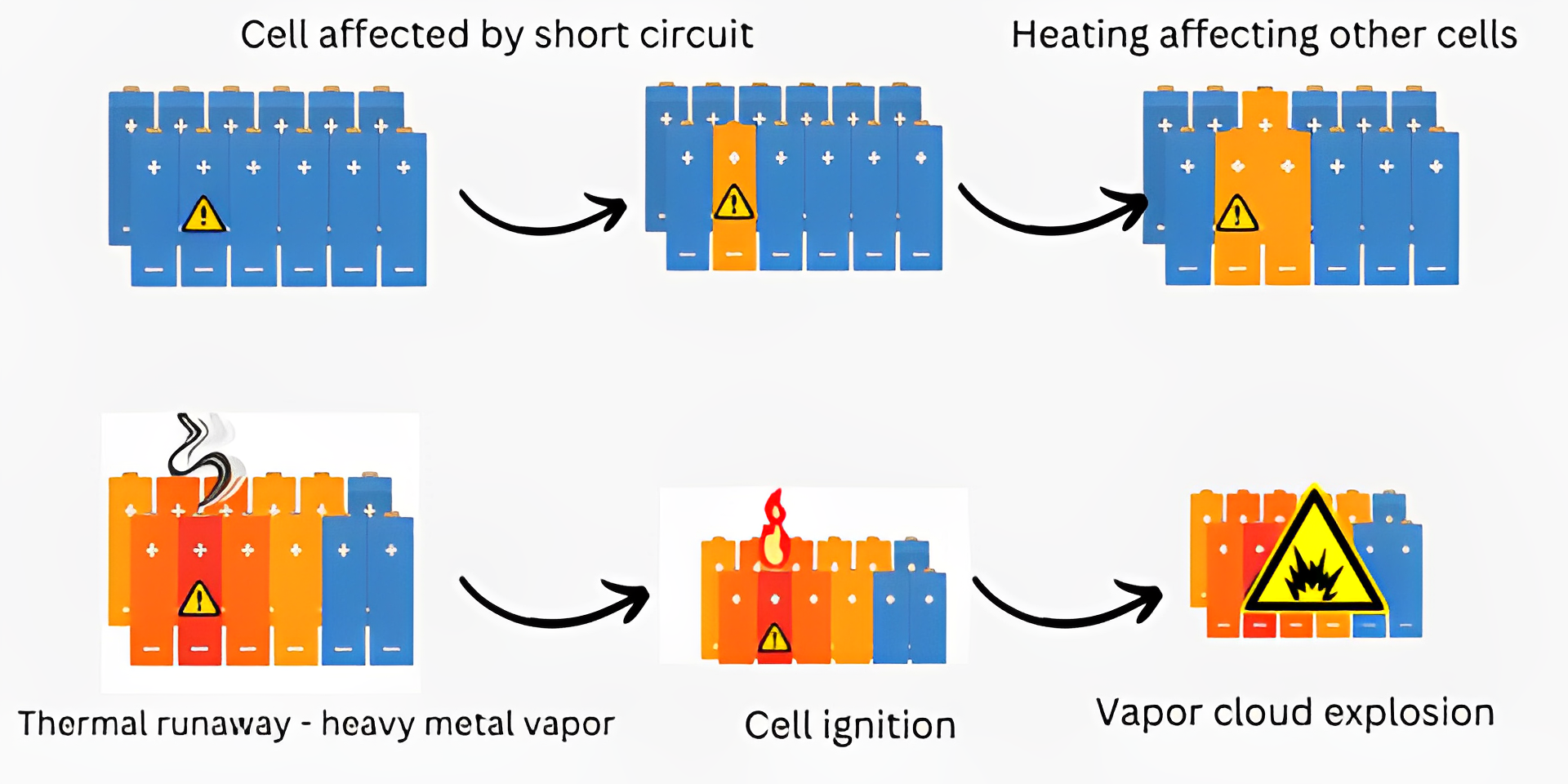

Thermal runaway is known as an uncontrolled exothermic reaction that results in a release of heat inside a cell, causing an exponential rise in temperature. When a cell can no longer dissipate heat as fast as it generates, it may experience venting, fire, or thermal runaway. The reasons behind catastrophic events in current lithium-ion cells can be categorized into three main types: electrical, mechanical, and thermal.

Thermal stability in Lithium (Li) Ion batteries reduces due to the following reasons:

| Electrical abuse | Mechanical abuse | Thermal abuse |

|

|

|

Thermal Runaway

Figure: Thermal runaway propagation

Reducing Thermal runaway is a critical application for simulations that require high-accuracy results. As E2W and E3W have many end-use cases, they need the battery and battery thermal management systems (BTMS) to be configured for each use case. Inefficient designs can lead to hazardous battery pack explosions due to extreme temperature, voltage, and charge/ discharge rate.

Quantum-powered Design Optimization can be used for creating safe external battery casing to reduce suppression challenges associated with battery pack designs. It can predict multiple external conditions that lead to thermal, mechanical, or thermal abuse.

Most E2W and E3W OEMs opt for swappable and portable battery packs for their electric scooter and rickshaws. This has many advantages like fast recharge of the packs together with packing more capacity into the scooter. However, connecting two or more batteries of like voltages and capacities is yet another design challenge for engineers designing BTMS.

Read More: EV Thermal Management Systems: Its Importance in Electric Vehicle

Challenges associated with designing safe BTMS:

- Simulating complex behavior of Batteries with multiple loading conditions

- Estimating overvoltage, under-voltage, and overtemperature cut-off

- Predicting SOH (State of Health) and SOC (State of Charge) of Li-Ion Batteries in large numbers

- Simulating accurate chemical behavior under different conditions

The battery makes up 25% of an EV’s total cost, and half of that battery cost is materials. Simulations to optimize battery chemistry with new materials and components can reduce this cost. In addition, it can help researchers identify the sweet spot between faster charging times and a battery’s expected life. However, modeling these simulations requires the consideration of several variables. As E2W and E3Ws are used for various loads and conditions, especially in South East Asia, several external factors come into play.

Quantum Powered Simulation can explore better design while considering multiple factors such as loading conditions (Voltage and currents), mechanical stresses, and heat dissipation. Accordingly, it improves the Rapid cooling of Lithium-Cells and predicts materials for better thermal barriers used between batteries.

Areas, where Quantum Powered Simulation can improve to reduce thermal runaway problems:

- High-fidelity thermal analysis

- Optimized Structural designs

- Multi-objective optimization for better battery pack designs and thermal performance of battery cooling

Battery OEMs and Manufacturers must consider many criteria, such as size, material cost, manufacturability, reliability, and safety. In addition, they also need various external factors for designing the battery components. This complexity makes simulations by current techniques very hard to optimize due to the heavy computing resources required to perform these calculations.

Therefore, exploring more advanced computing techniques like Quantum computing are required to solve these problems in a realistic timeframe.

BQP recently released its alpha version of BQPhy with its proprietary quantum-inspired algorithms integrated as part of a CAE solver, leveraging the power of quantum computing that can run on both HPC and quantum computers. QI optimization algorithms compute faster than traditional optimization methods and offer a higher exploration rate with the same amount of computational resources. In addition, this approach works best with a wide range of variables and constraints and can readily consider external factors such as reliability and safety.

Read More:- Electric Vehicle Charging Infrastructure & Opportunities And Challenges