I Believe That Water Will One Day Be Employed As Fuel, That Hydrogen And Oxygen Which Constitute It, Used Singly Or Together, Will Furnish An Inexhaustible Source Of Heat And Light (Energy), Of An Intensity Of Which Coal (Hydrocarbon) Is Not Capable. – Jules Verne (1874)

Table of Contents

Background

Life as we know on earth is said to be “A Carbon Based Life Form[1]” because the carbon atoms can bond with many other atoms to create complex hydrocarbons. These complex compounds are also sources of life & energy. Fossil fuels, such as Crude oil, coal, and natural gas (forming about 85% of the global energy demand), all are some form of hydrocarbons (CxHy), the complex compounds of Carbon & other elements. The carbon atoms are the “skeleton” and atoms of other elements get attached to them to create petroleum (crude oil) and natural gas, which serve as fuels, lubricants, and raw materials for the production of plastics, rubbers, solvents, explosives, and many other industrial chemicals. Most of these complex hydrocarbons (oil) normally occur naturally and were formed by the forces of temperature and weight over millennia from the plant and animal fossils. These hydrocarbons, being liquid have excellent flexibility as fuel because of their transportability whereas other fuels being solid (coal) or gas (Natural Gas or Hydrogen) have limited portability.

Also, with an energy of 42~47 MJ/kg, the oil contains over 50% more chemical energy than the highest quality of coal (17~25 MJ/ kg). With these two factors alone, one supertanker of 2 million barrels of oil can provide the same amount of energy as that of 30 full coal trains of 100 wagons, carrying 115 metric tons of coal each. While natural gas contains more energy (42~55 MJ/Kg), its gaseous nature makes it difficult to transport, & requires a complex network of piping.

Crude oil also has many ingredients in it, in the form of hydrocarbon chains of different lengths, which once separated via distillation and cracking, are used in manufacturing a wide variety of products e.g. Kerosene, Gasoline, Diesel, Heavy fuel oils, Naphtha, Asphalt, BTX aromatics, refinery gas & even the Hydrogen also. So, when a large petroleum reserve was discovered, near Beaumont, Texas, in the year 1901 (“The Texas Oil Boom”), the so-called “Energy Rush” started at the beginning of the 20th century which was followed by the automobile revolution driven by ICEVs and pushed up the demand for oil as a transport & energy fuel to a much higher level.

During the same time (i.e. around 1907) Bakelite[2] was discovered by Belgian-American chemist Leo Baekeland. By 1910, Bakelite got commercialized. As it was cheap and durable, it quickly became the preferred choice to create many daily-use household items. During 1920~1950 more R&D in this field led to the creation of plastics like polyvinyl chloride (PVC), Plexiglas, polyethylene (PE), polypropylene (PP), and polyurethane (PU) foam, etc. Not to mention the tens of thousands of other chemical products such as paints, detergents, soaps, coatings, colorants, pharmaceuticals, and explosives were also derived from Oil. This was just the beginning of the “Oil Age” or in other words “Plastic Age” – and both have a common meaning which is “Age of Hydrocarbons”.

Burning fossil fuels (hydrocarbons) has been under discussion since it was discovered but has gained momentum in recent years as with consumption of hydrocarbons increasing exponentially, their impact is becoming dangerously serious over the last few decades, impacting many life forms. It has been found facing right in front of us and thus has been covered in many studies related to environmental degradation, fall in AQI (Air Quality Index), fluctuating climatic conditions, and falling human health as well as global warming, rising sea levels, air pollution, acid rains, damage to marine life due to oil spills and ocean acidification.

Unfortunately, despite all these known negative impacts of using hydrocarbons (i.e. primarily Carbon) which contain two basic elements carbon & Hydrogen, mankind somehow remained obsessed with only carbon and has worked hard to increase the energy yield from this element only, just because it was found to be easy to manage.

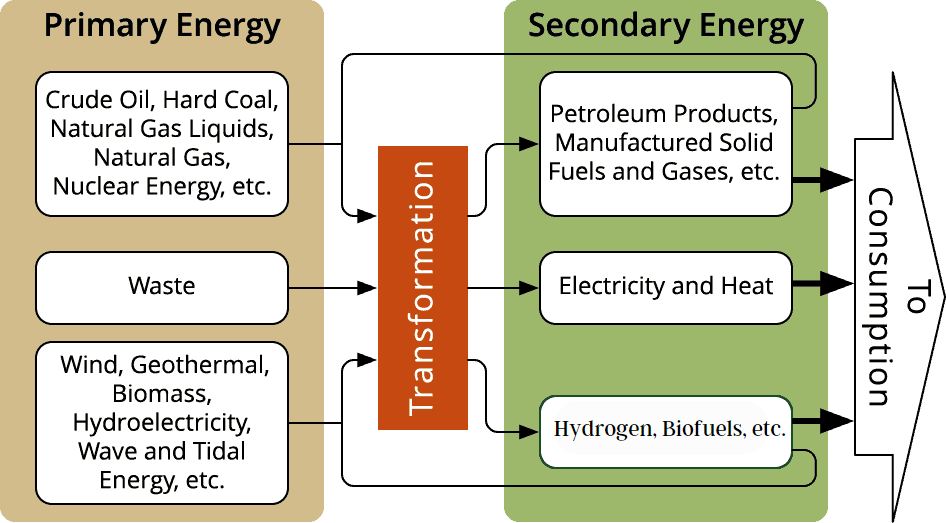

No serious efforts were made to evolve Hydrogen as an alternative energy source, despite well-known fact that Hydrogen was an energy denser, a much better & cleaner contender for energy generation. However, the good part is that despite Hydrogen being the “Secondary Form Of Energy”, the focus is now shifting to Hydrogen because it is “THE SIMPLEST AND MOST ABUNDANT ELEMENT ON EARTH”. Considering all factors, today’s world is hurrying and trying to develop alternative fuels. Among various alternatives, Hydrogen fuel seems to have highest potential. For the past 40 years, environmentalists and several industrial organizations have been promoting Hydrogen fuel as the solution to almost all the problems risen due use of hydrocarbon-based fuels and possesses all the key criteria for an ideal fuel such as inexhaustibility, cleanliness, and convenience. Hydrogen is now being evaluated and promoted worldwide as an environmentally benign replacement for gasoline, heating oil, natural gas, and other carbon fuels in both transportation and non-transportation applications. Similar to electricity, Hydrogen is a high-quality energy carrier, which can be used with excellent efficiency and near-zero emissions at the point of use. It has been technically demonstrated that Hydrogen can be used for transportation, heating, and power generation, and could replace current fuels in all their present uses.

History of Hydrogen

In the early 1500s, the alchemist Paracelsus noted that when iron filings were added to sulfuric acid, it released bubbles that were flammable. In 1671 Robert Boyle made the same observation. However, neither followed up their observations and so when in 1766, Henry Cavendish collected these bubbles and observed them to be different from other gases, he was credited for discovering this “New Gas”.

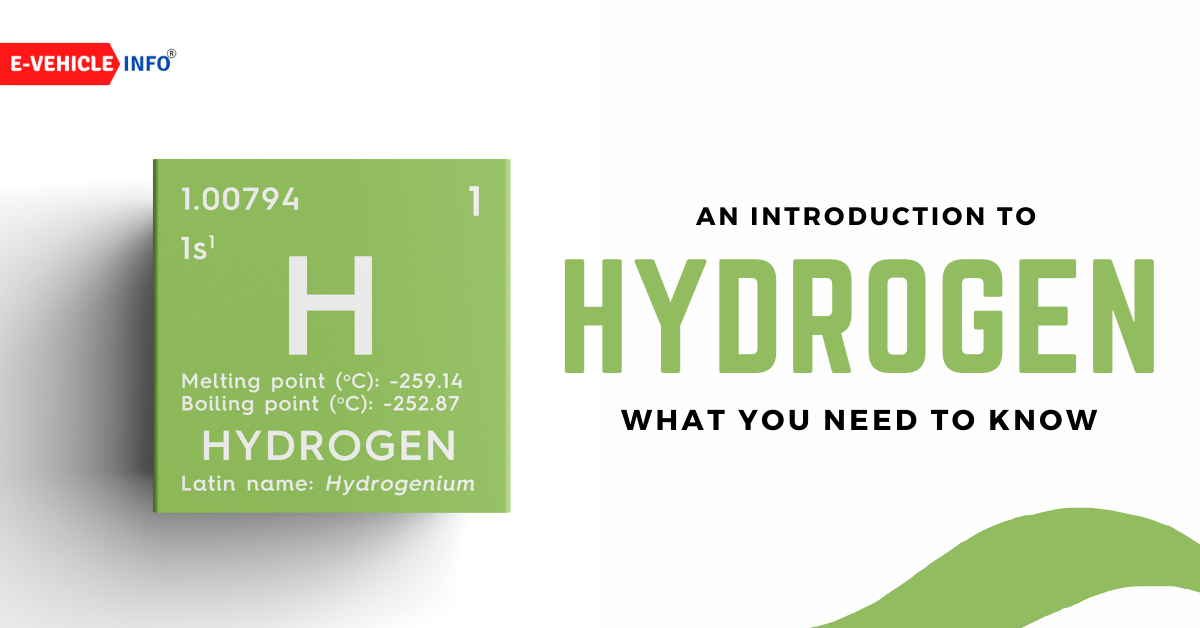

So officially Henry Cavendish, an English physicist, made the discovery of hydrogen in 1766. He later noticed that this gas when burned, forms water, thereby ending the belief that water was an element. Antoine Lavoisier gave the name “HYDRO-GEN,” which means “the water-former,” in 1783. With an atomic number of 1, Hydrogen is the lightest known element & first in the Periodic table. At standard storage conditions, Hydrogen is a gas of diatomic molecules having the formula H2. Hydrogen is colorless, odorless, tasteless, non-toxic, and highly combustible. Hydrogen is the most abundant chemical substance in the “Universe”, constituting roughly 75% of all normal matter. Stars such as the Sun are mainly composed of Hydrogen in the plasma state. Most of the Hydrogen on Earth exists in molecular forms such as water and organic compounds. It is also one of the most important and mysterious elements of the periodic table as it possesses many unique properties that predetermine its importance in various processes in physics, chemistry, and biology.

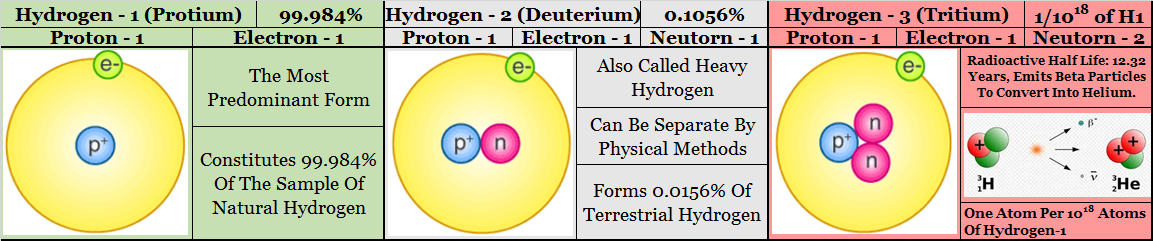

In 1931, Harold Urey and his colleagues at Columbia University detected a second, rarer, form of Hydrogen which had twice the mass of normal Hydrogen, and they named it Deuterium (also known as Hydrogen-2). It was followed by the discovery of another form of Hydrogen, which was renamed Tritium (Hyddroge-3) in 1934 by the physicists Ernest Rutherford, M.L. Oliphant, and Paul Harteck, when deuterium was bombarded with high-energy deuterons. Tritium is radioactive with a half-life of 12.32 years.

However, to know & understand Hydrogen, we must go back in time of Big Bang, the instant when the universe is supposed to have started. The Big Bang is expected to have occurred between 13.3~13.9 billion years ago. Scientists estimate that at the tiny fraction of second, the temperature of the entire universe was about 1000 trillion degC post the explosion. What followed after Big-Bang, was the exponential expansion of the universe called the “period of cosmic inflation”. With time as the temperature fell down the protons and neutrons started to get formed, further cooling led to the next phase of transition, i.e. formation of physical forces and elementary particles in their modern forms. The emergence of neutral Hydrogen atoms throughout the universe occurred about 379,000 years after the Big Bang during the recombination epoch, when the plasma had cooled enough for electrons to remain bound to protons. Slowly, other substances were formed which went on to form the first stars and ultimately galaxies, quasars, clusters of galaxies, and super clusters etc. By virtue of being the very first element of Universe, Hydrogen dominates within the presently known universe as it is the most abundant element in the cosmos, (Hydrogen makes up 88.6% of the composition by weight and 93% of all the atoms in the known universe). The chemical evolution of the stars is crucially determined upon the Hydrogen fusion. In the interstellar space Hydrogen exists as separate molecules, atoms, and ions and can form molecular clouds of different in size, density, and temperature.

Hydrogen & Its Isotopes[3] – Plutonium (Primary Hydrogen), Deuterium, Tritium

On Earth, Hydrogen is abundantly found in water (H2O) (which covers about 71% of the Earth’s surface), in fossil fuels (Hydrocarbons), and in all plants and animals (human body is about 60% water), and yet Hydrogen (H2) is not a primary fuel in the same sense as natural gas, oil, and coal. There are no known geological deposits of Hydrogen from where it can be taken out as a primary energy source, rather, Hydrogen is an energy carrier, like electricity & is a secondary form of energy.

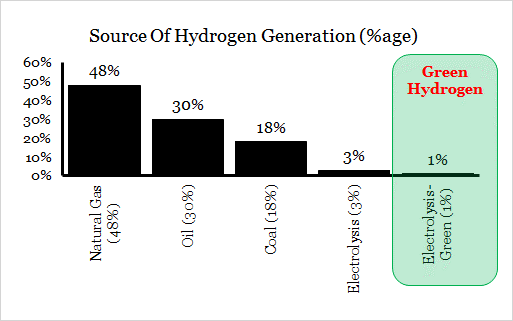

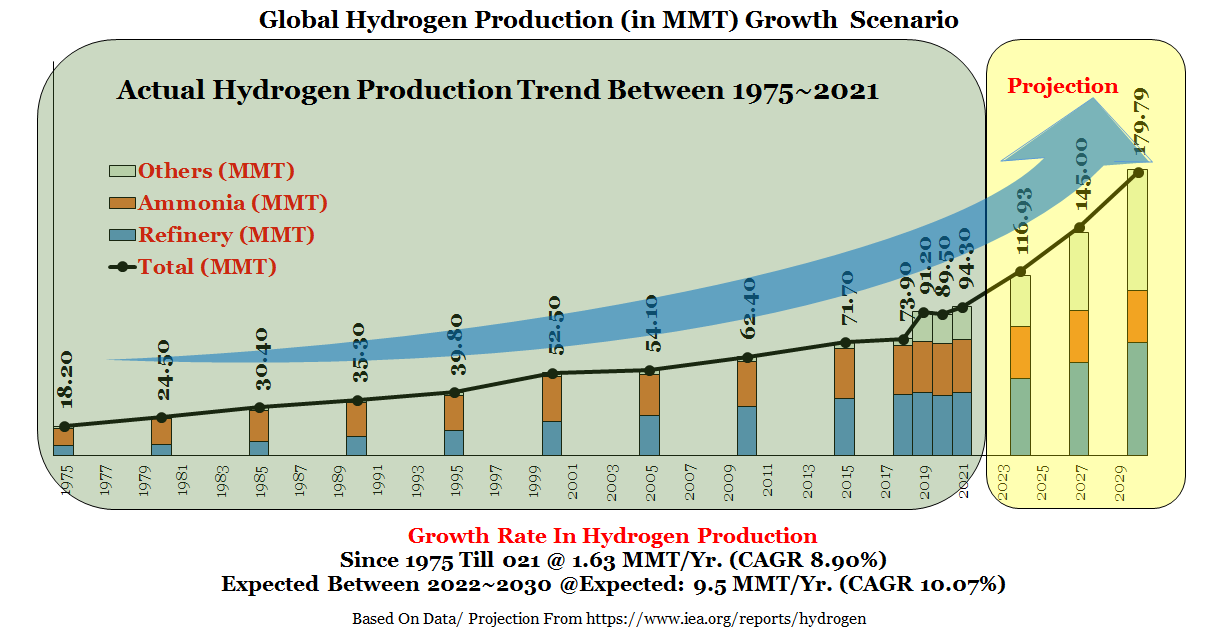

Global Hydrogen demand touched 94 MMMT in 2021, mainly driven by the recovery of industrial activities, post COVID-19 and this demand surpassed the historical maximum of 91.2 MMMT achieved in 2019. However, most of this demand was met by Hydrogen produced from fossil fuels (Hydrocarbons). As of date, the demand for Hydrogen has been mainly driven by traditional applications e.g. petro refineries and chemical sectors, with very limited penetration in new applications such as transport, industry, building heating, Hydrogen-based DRI[4] (Direct Reduced Iron Making), bulk storage of energy & generation of power, & represents only 0.04% of global Hydrogen demand. Of late, most of this new demand is concentrated in road transport, which observed a significant increase in recent times, due to the accelerated deployment of FCEVs, particularly fuel cell-driven heavy-duty trucks in China. By 2030 the Hydrogen demand is expected to touch around 180 MMMT, with nearly half of that demand is expected to come from new applications, particularly in heavy industry, power generation, and the production of Hydrogen-based fuels (FCEVs). Unfortunately, major Hydrogen production today is still based on fossil fuel technologies.

In today’s scenario, Hydrogen with low emission represents less than 1% of total Hydrogen production. But on the brighter side, low-emission Hydrogen production grew by 9% in 2021, because of the commissioning of projects across the globe, when more than 200 MW of electrolysers started operating, including 160 MW in China (having more than 7700 heavy-duty FCEV and more than 30 MW in Europe, driven by green energies.

Hydrogen As Alternative Fuel

Since the start of the industrial revolution and increasing world population, which continuously desired higher living standards with better air quality, the energy demands have been continuously increasing. Unfortunately, as said many times above, most of this energy requirement, two-thirds of which is required for transportation and heating is met from petroleum or natural gas. Between 1901 (when the very first crude oil bore well was made in Texas) and 1908 (when Henry Ford introduced Model T), these two fuels had almost become energy standards. Still, Hydrogen as clean energy retained its charm and kept on gaining more momentum as the permanent solution to the various environmental & other problems which were getting identified because of continually increasing consumption of fossil fuels.

On March 18-20, 1974, the landmark theme conference was opened at the Playboy Plaza Hotel in Miami Beach, with the participation of more than 700 scientists from some 80 countries, where Hydrogen Energy System (HES) as the permanent solution, to the depletion of fossil fuels and the global environmental problems being caused by their utilization. It immediately caught the imagination and attention of socially contentious energy and environmental scientists and engineers. R&D activities around the world were initiated to develop the technologies needed for the introduction of the Hydrogen energy system. It took a quarter of a century to develop most of the technologies required. The Hydrogen energy system started making inroads in the energy field early in the 21st century when several types of fuel cells[5] were developed for efficient conversion of Hydrogen to electricity, as well as heat.

Industries Involved in Hydrogen Technology

The USA, Germany, and Japan started using fuel cells to produce electricity and to heat homes and buildings. Hydrogen-fueled forklifts started replacing battery-powered forklifts in warehouses. Several countries also started experimenting with Hydrogen-fueled buses (Foton & Mercedes Benz). Major automobile manufacturers around the globe started developing technologies for Hydrogen driven cars (Toyota Mirai/ Hyundai Nexo, Honda Clarity etc.). Railway companies also started experimenting with Hydrogen-fueled locomotives (e.g. China South Rail Corporation/ Alstom). A few cities also started experimenting with trams running on Hydrogen. Even Boeing and Airbus are now studying the feasibility of Hydrogen-fueled passenger planes while a Hydrogen-powered supersonic private plane is also under development. Interestingly, Hydrogen and Electricity are generally considered as opposite sides of the same energy. While Electricity (derived from any source) can be readily used to produce Hydrogen via electrolysis, Hydrogen can only be consumed to produce pollution-free electricity via a fuel cell.

Advantages of Hydrogen

(1) it can be produced from and converted into electricity at relatively high efficiencies;

(2) one of the materials to produce it is water (Interestingly water is again formed when Hydrogen is burned to generate electricity), and is available in abundance;

(3) it is a completely renewable fuel;

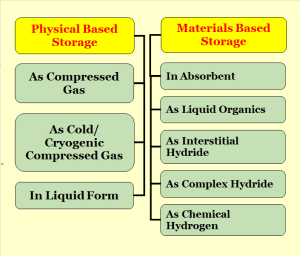

(4) it can be stored in gaseous form (convenient for large-scale storage), in liquid form (convenient for air and space transportation), or in the form of metal hydrides (convenient for surface vehicles and other relatively small-scale storage requirements);

(5) it can be transported over large distances through pipelines and/ or via tankers;

(6) it can be converted into other forms of energy in more ways and more efficiently than any other fuel (such as catalytic combustion, electrochemical conversion, and hydriding); and

(7) it is environmentally friendly when produced from water using renewable energies since its production, storage, transportation, and end use do not produce any pollutants (except for small amounts of nitrogen oxides when it is burned with ambient air), greenhouse gases, or any other harmful effects on the environment.

| Share of Hydrogen Generation Sources | Major Uses For Hydrogen |

| Transport Application |

| Stationary/ Domestic Electricity/ Heat Generation | |

| Locally Stored Energy | |

| Balancing Of Renewable Electricity Production | |

| Portable Electronics | |

|

Hydrogen Production & Classification

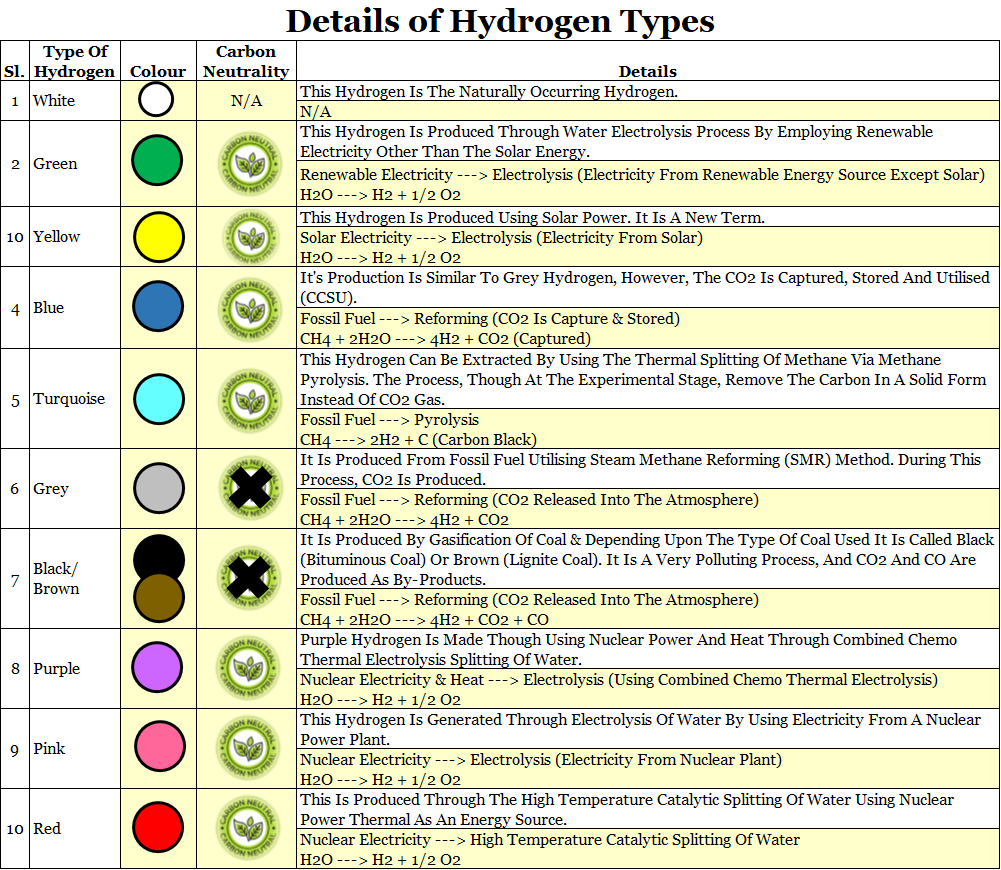

As stated above, since Hydrogen is a secondary form of energy & hence needs to be produced using any of the primary energies, industry has created a set of colour codes to distinguish the type of Hydrogen being produced, based upon the process being followed to produce it, and the impact of those processes on the environment while producing the Hydrogen. Green Hydrogen, which is the present day’s buzzword in the energy sector, is supposed to be produced using Green Energy[6].

Methods of Hydrogen Production

- Coal, Oil Gasification

- Partial Oxidation (with (CO2 Capture)

- Natural Gas Steam Reforming (with CO2 Capture)

- Pyrolysis Plasma Reforming

- Solar Energy Electrolysis of Water

- Photolytic Splitting Of Water

- Thermal Splitting Of Water

- Nuclear Electrolysis of Water

- Thermal Splitting of Water

- Wind/ Hydro/ Water/ Geo Thermal Electrolysis Of Water

- Bio Mass Fermentation/ Gasification/ Pyrolysis

Types of the Hydrogen

However, this colour coded nomenclature is only used to facilitate intellectual discussions, since as of now nothing has been standardized about them. It is high time that policymakers must come out with a universally accepted standard color coding of Hydrogen, based on quantified measurement of greenhouse gas (GHG) emissions from each of the methods of generating Hydrogen, during their complete life-cycle. This is important as there are many processes of Hydrogen generation that certainly do not fully fall under one colour (e.g. mixed Hydrogen sources, electrolysis with coal-based electricity).

Methods of storing Hydrogen

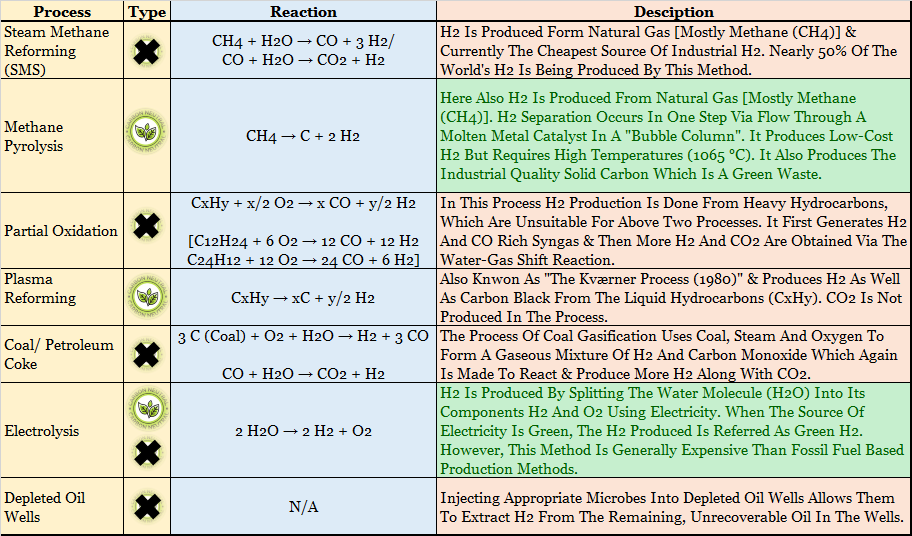

Hydrogen can be produced using a variety of chemistries and utilizing energies derived from both renewable and nonrenewable sources, through many different processes, some of which are given below:

Different Common Processes To Produce Hydrogen

However, in the real world, till now the two widely used processes for commercial production of Hydrogen have been in use, the reformation of natural gas and electrolysis of water (with multiple sources of electricity).

The recent rise of Hydrogen economy has revived the focus on the development of new Hydrogen technologies which are safe and affordable for generating, storing, distributing & utilizing Hydrogen as an alternative to fossil fuel. The initiative for development of these technologies to produce Hydrogen and its utilization are based on the premise that Hydrogen is in abundant supply on Earth. Still, since most of the Hydrogen on Earth is not available as free gas, BUT is bonded either as hydrocarbons or water, which has no fuel value unless separated (this separation also needs energy), the major challenge related to Hydrogen has been, in its efficient & safe harnessing so that it could be used as fuel.

At present, Hydrogen production is a growing industry and in the year 2021 alone about 94.3 MMT of Hydrogen was produced which in energy terms was equivalent to about 365.65 Million KL of Oil. It is worth noting that during same year (2022) world produced 5797.22 Million KL of Oil. Thus Hydrogen forms a healthy 6.31% of overall global energy scene (however out of this 6.31% of hydrogen energy produced, 2.26% is used in the refineries, 1.38% is used in ammonia production while only the balance 1.38% was used in other areas including basic power system & mobility network). And with a CAGR of 11%, the future certainly looks bright for this energy source. At present, Hydrogen is primarily consumed in two nonfuel uses:

(1) about 60% produce NH3 to produce fertilizers

(2) about 40% in refinery, chemicals, and petrochemical sectors.

If non-conventional resources, such as wind, solar, or nuclear power for Hydrogen production were available, the use of Hydrogen for hydrocarbon synfuel production could expand by 5- to 10-fold.

Hydrogen In Fuel Cell Vehicles (FCVs)

Going back to the history of Fuel cells, it was in 1839, when Sir William Graves first demonstrated the principle of fuel cell. However, it was the oil crisis in 1973 fastened the development of fuel cells in the search of alternative energy sources especially for automobiles which were one of the largest consumers of petroleum fuel thus the EVs with Fuel cells started gaining momentum as, even in this time, mass commercial production of Lithium Ion Cells (LICs) was about 20 years away[7].

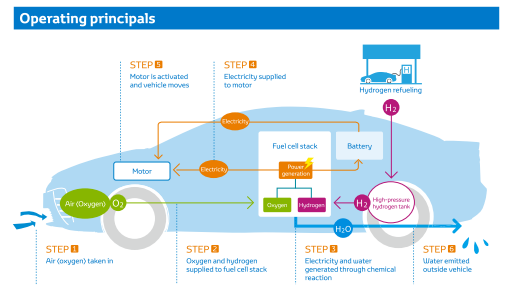

Back then, there were only two commercially available batteries – the Lead Acid Batteries (LAB) and the Nickel Cadmium (NiCd) Batteries, having their own sets of challenges for applicability in the EVs. This prompted research into the development of improved Fuel Cells for future EVs. The Fuel Cell is an electrochemical device which combines Hydrogen with Oxygen to produce electricity, heat, and water. In these fuel cells, rather than applying a periodic recharge, the Hydrogen, which is stored in a pressurized container, is supplied as a fuel while the Oxygen is drawn from the air unlike IC Engines, the fuel cells do not generate energy through burning; but by electrochemical process. There are little or no harmful emissions. The only release is clean potable water (if burned with pure Oxygen) or a little bit of NOx (if burned with atmospheric air). There is no physical limit of energy generation except to the limit of storage of Hydrogen i.e. the tank capacity to store Hydrogen. In a way, Fuel Cells are analogous to the ICEs where instead of Gasoline, Hydrogen is stored in the tank. Till date, the cost of fuel cell technologies has been prohibitively high due to the cost of rare earth & pure materials. Although some improvements were made in the early 1990s, for improving the stack designs, which led to increased power densities thus reducing the cost of energy generation.

Over time, several variations of fuel cell systems have emerged. There several types of fuel cells are being developed for a large number of commercial applications which are summarized below:

Types of Fuel Cells

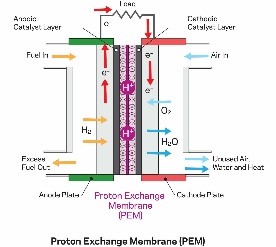

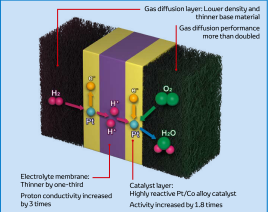

Proton Exchange Membrane Fuel Cell (PEMFC)

They Are Also Known As Polymer Electrolyte Membrane (PEM) Fuel Cells, & Were Developed Mainly For Transport, Stationary And Portable Applications. They Have Lower Operating Temperature Range (50 To 100 °C). PEMFCs Generate Electricity And Operate On The Opposite Principle To PEM (Polymer Electrolyte Membrane) Electrolysis. Challenges Include High Manufacturing Costs, Need Of Heavy Auxiliary Equipment, Pure Hydrogen, No Tolerance For Contaminates And Complex Heat And Water Management.

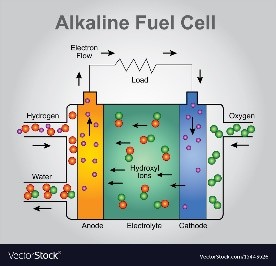

Alkaline Fuel Cell (AFC)

AFC, Also Known As Bacon Fuel Cells, Are The Most Developed Fuel Cell Technologies. Alkaline Fuel Cells Consume Hydrogen And Pure Oxygen, To Produce Potable Water, Heat, And Electricity. They Are Among The Most Efficient Fuel Cells, Having The Potential To Reach The Efficiency Level of 70%/ NASA Had Used Them During The Mid-1960S, In The Apollo-Series Missions And Later On The Space Shuttles.

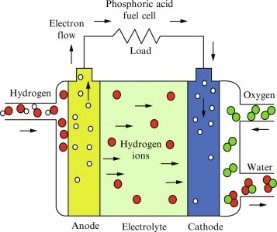

Phosphoric Acid Fuel Cell (PAFC)

PAFC Were Developed In The Mid-1960s And Field-Tested Since The 1970s. They Use Liquid Phosphoric Acid As Electrolyte & Were The First Fuel Cells To Be Commercialized. They Have Much Better Stability, Performance, And Cost, Compared To Other FCs. And Hence Were Widely Used In Early Stationary Applications.

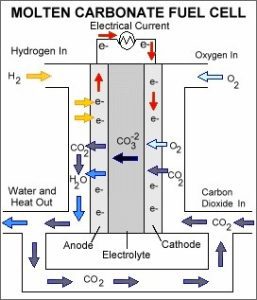

Molten Carbonate Fuel Cell (MCFC)

MCFCs Use Electrolyte Composed Of Molten Carbonate Salt Mixture Suspended In A Porous, Which Is A Chemically Inert Ceramic Matrix Of Beta-Alumina Solid Electrolyte (BASE). They Operate At Extremely High Temperatures Of >650°C & Use Natural Gas &/or Biogas. They Have Efficiency of About 60% (However, When The Waste Heat Is Captured And Used In These Fuel Cells, Overall Fuel Efficiencies Can Be As High As 85%), Which Is Much Higher Than The 37–42% Efficiencies Of A PAFCs.

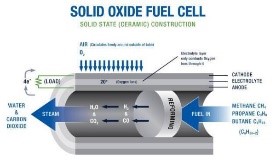

Solid Oxide Fuel Cell (SOFC)

SOFC Produces Electricity Directly From Oxidizing A Fuel (CH4, C2H6, C3H8, C4H10) Using A Solid Oxide Or Ceramic Electrolyte & Has Advantage Of High Efficiency, Long-Term Stability, Fuel Flexibility, Low Emissions, And Relatively At Low Cost. They Have Efficiency Upto 60%. The Biggest Disadvantage Is Its Longer Start-Up Times And Compatibility Issues.

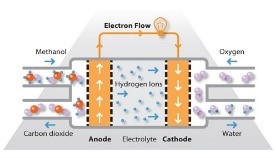

Direct Methanol Fuel Cell (DMFC)

DMFCs Are A Subcategory Of PEFCs In Which Methanol Is Used As The Fuel Which Can Be Transported Easily And Is An Energy-Dense Yet Reasonably Stable Liquid At All Environmental Conditions. The Efficiency of DMFCs As of Now Is 30%~40% [Theoretically Possible Limit Is 97%]. Research Is Going On To Increase The Operational Efficiency.

The most common Fuel Cell system used in EVs and portable electronics is the Proton Exchange Membrane Fuel Cell (PEMFC) system as it allows compact designs and achieves high energy to weight ratio. It also has an added advantage of getting a quick start-up as soon as Hydrogen is supplied. The stack runs at a relatively comparatively lower temperature of about 80°C (176°F) & the efficiency is about 50% (in comparison, the ICEs operate at about 15% efficiency). However, the limitations of the PEMFC system are its high manufacturing costs and the need for a complex water management system needed for its stack which contains Hydrogen, oxygen, and water. Unfortunately, if this stack gets dry, the cell develops a high flow resistance for gases, and then water must be added to get the system going. But if slightly more water than what is needed, gets added, it causes flooding in the Fuel Cell, impacting its operations.

The PEMFC also has a limited operating range of temperature. While freezing water can damage the stack (hence additional heating elements are fitted to keep these fuel cells within an acceptable temperature range), if the warm-up is slow, then the performance goes down. Disposal of heat is also a concern when the temperature rises too high. Due to these operational issues, the PEMFC requires a complex set of accessories e.g. compressors, pumps, and other sub-systems, which on one side make PEMFCs physically complex, these sub-systems also consume about 30% of the energy generated. Although the stationary & uniformly loaded PEMFC stack which is made to run continuously has an excellent life of 40,000 hours, it is the intermittent start and stop conditions in EVs which lead to induce drying and wetting, causing membrane stress. These stresses on membrane, effectively reduce the effective service life of PEMFC in EVs by 1/10th to 4,000 hours (i.e. about 2 years of life if the EVs are made to run 6 hours a day). Similar to BEV (in which battery replacement cost is prohibitively high), the replacement cost of the stack in FCEV is also very high. Despite the above said challenges associated with the PEMFCs, they are still considered the most promising fuel cells for cars and light trucks.

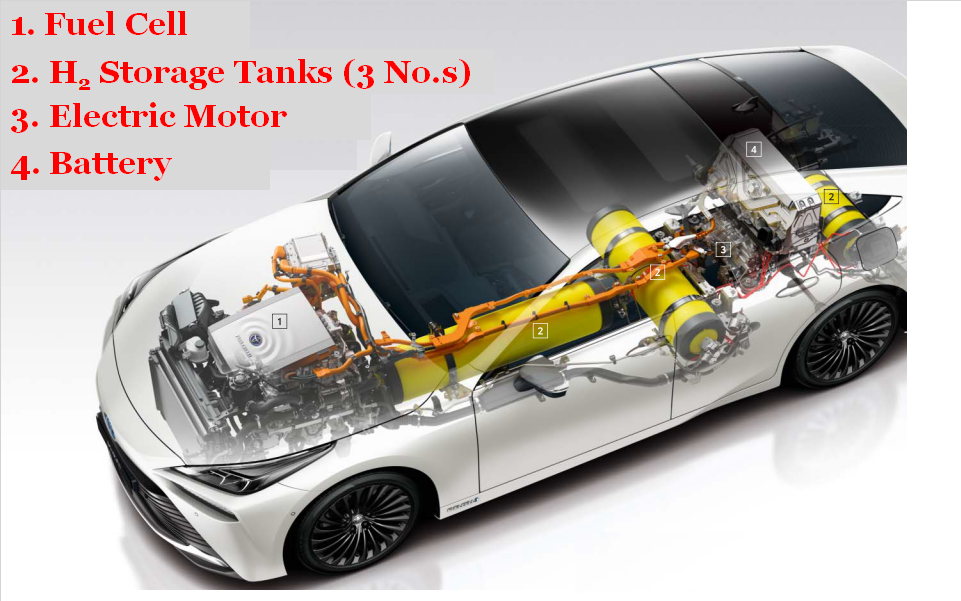

5 basic Components of a Hydrogen Fuel Cell

- Fuel Cell Stack – An Aggregate Of Numerous Fuel Cells That Combine Oxygen And Hydrogen To Generate Electricity And Power The Electric Motor

- Fuel Tank – Hydrogen Gas Is Stored In Carbon-Fiber Reinforced Tanks To Provide Fuel To The Fuel-Cell Stack

- Electric Motor – Powers The Car Using Energy Produced In The Fuel Cell Stack

- Battery – Captures Energy From Regenerative Braking And Provides Additional Power To The Electric Motor

- Exhaust – The Byproduct Of The Reaction Occurring In The Fuel Cell Stack Is Water Vapor, Which Is Emitted Through The Exhaust

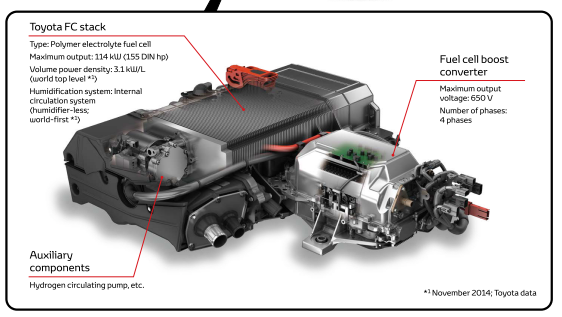

| Toyota Mirai, FCV 2022 Using H2 As Fuel | |

| Main Components | Operating Principle |

|  |

| Fuel Cell Stack Assembly Structure And Main Specifications | New Cell Of Mirai (Volume Power Density 3.1 KW/L) |

|  |

Challenges Of Fuel Cell EVs/ Cars

Hydrogen Fuel Cells are not efficient

In 2008, Professor Jeremy P. Meyers, in the Electrochemical Society journal Interface wrote that fuel cells “are not as efficient as batteries, due primarily to the inefficiency of the oxygen reduction reaction. … They make the most sense for operation disconnected from the grid, or when fuel can be provided continuously. For applications that require frequent and relatively rapid start-ups … where zero emissions are a requirement, as in enclosed spaces such as warehouses.”

Also in 2008, Wired News reported that “experts say it will be 40 years or more before Hydrogen has any meaningful impact on gasoline consumption or global warming, and we can’t afford to wait that long. In the meantime, fuel cells are diverting resources from more immediate solutions.”

In 2008, Robert Zubrin, the author of Energy Victory, said, “Hydrogen is just about the worst possible vehicle fuel“. If Hydrogen could be produced using renewable energy, “it would surely be easier simply to use this energy to charge the batteries of all-electric or plug-in hybrid vehicles.”

The Los Angeles Times wrote in 2009, “Any way you look at it, Hydrogen is a lousy way to move cars.” The Washington Post asked in November 2009, “Why would you want to store energy in the form of Hydrogen and then use that Hydrogen to produce electricity for a motor, when electrical energy is already waiting to be sucked out of sockets all over America and stored in auto batteries…?”

Assessments since 2020 have concluded that Hydrogen vehicles are still only 38% efficient, while battery EVs from 80% to 95% efficient. A 2021 assessment by CleanTechnica concluded that while Hydrogen cars are far less efficient than electric cars, the vast majority of Hydrogen being produced is polluting grey Hydrogen, and delivering Hydrogen would require building a vast and expensive new infrastructure, the remaining two “advantages of fuel cell vehicles – longer range and fast fueling times – are rapidly being eroded by improving battery and charging technology.” A 2022 study in Nature Electronics agreed.

High Cost

In 2013, the Motley Fool stated that “there are still cost-prohibitive obstacles for Hydrogen cars relating to transportation, storage, and, most importantly, production.” During the same period, Volkswagen’s Rudolf Krebs also indicated that “no matter how excellent you make the cars themselves, the laws of physics hinder their overall efficiency. The most efficient way to convert energy to mobility is electricity.” He elaborated: “Hydrogen mobility only makes sense if you use green energy, but … you need to convert it first into Hydrogen with low efficiencies where you lose about 40% of the initial energy. You then must compress the Hydrogen and store it under high pressure in tanks, which uses more energy. And then you have to convert the Hydrogen back to electricity in a fuel cell with another efficiency loss”. Krebs continued: “In the end, from your original 100 percent of electric energy, you end up with 30 to 40 percent.”

Hydrogen Extraction

In 2014, electric automotive and energy futurist Julian Cox[8] wrote that producing Hydrogen from methane “is significantly more carbon intensive per unit of energy than coal.” While former Dept. of Energy official Joseph Romm[9] concluded that renewable energy cannot economically be used to make Hydrogen for an FCV fleet “either now or in the future.” GreenTech Media’s analyst reached similar conclusions.

A 2017, analysis published in Green Car Reports found that the best Hydrogen fuel cell vehicles consume “more than three times more electricity per mile than an electric vehicle … generate more greenhouse-gas emissions than other powertrain technologies … and have very high fuel costs. … Considering all the obstacles and requirements for new infrastructure (estimated to cost as much as $400 billion), FCEVs seem likely to be only a niche technology. In 2017, Michael Barnard, writing in Forbes, listed the continuing disadvantages of Hydrogen fuel cell cars and concluded that “by about 2008, it was very clear that Hydrogen was and would be inferior to battery technology as a storage of energy for vehicles. By 2025 the last holdouts should likely be retiring their fuel cell dreams.” A 2019 video by Real Engineering[10] noted that using Hydrogen as a fuel for cars does not help to reduce carbon emissions from transportation. 95% of present-day Hydrogen is still produced from fossil fuels and releases carbon dioxide, and producing Hydrogen from water is an energy-consuming process.

Hydrogen Storage

Very large volume storage of Hydrogen is necessary for an adequate driving range. And storing Hydrogen requires more energy either to cool it down to the liquid state or to put it into tanks under high pressure, and delivering the Hydrogen to fuelling stations requires more energy and may release more carbon. The Hydrogen needed to move an FCV a kilometer costs approximately eight times as much as the electricity needed to move a BEV the same distance. Also in 2019, Katsushi Inoue, the president of Honda Europe, stated, “Our focus is on hybrid and electric vehicles now. Maybe Hydrogen fuel cell cars will come, but that’s a technology for the next era.”

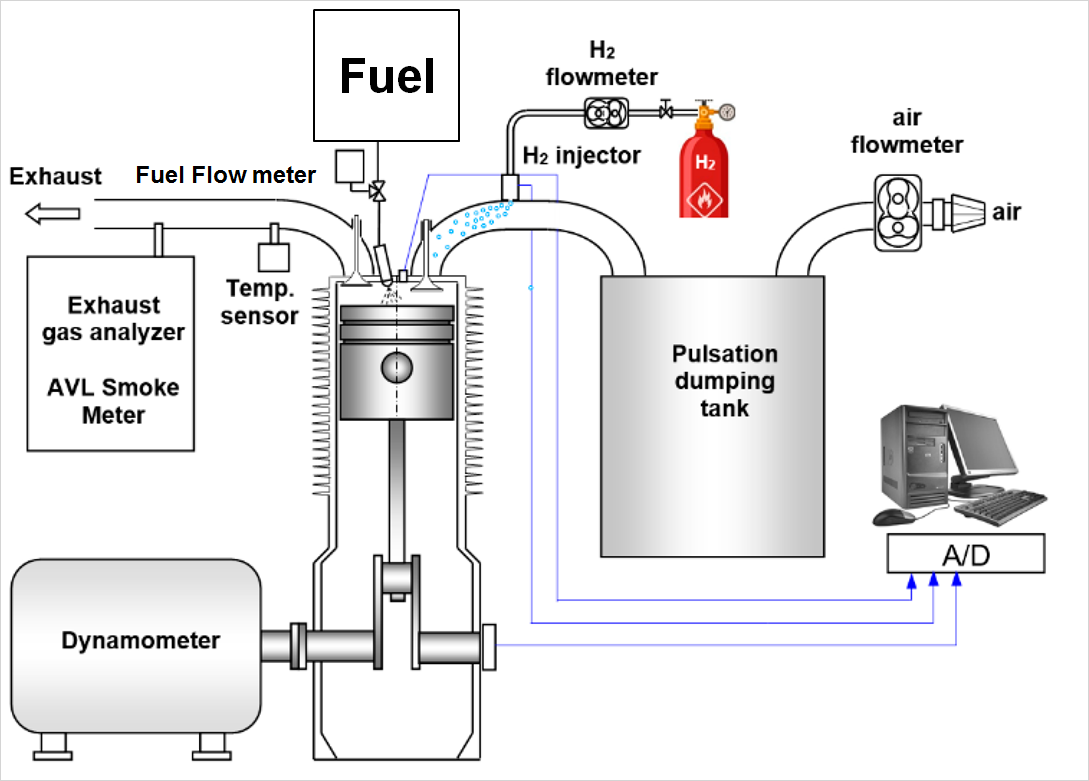

Hydrogen In ICEVs As Directly Injected Fuel

The De Rivaz engine, the first internal combustion engine that used a hydrogen/oxygen combination, was developed in 1806 by Francois Isaac de Rivaz. The earliest attempt at developing a Hydrogen IC engine (HICE) was reported by Reverend W. Cecil in 1820. Cecil presented his work before the Cambridge Philosophical Society in a paper entitled “On the Application of Hydrogen Gas to Produce Moving Power in Machinery.” The engine itself operated on the vacuum principle, in which atmospheric pressure drives a piston back against a vacuum to produce power. The vacuum is created by burning a Hydrogen-air mixture, allowing it to expand and then cool. Although the engine ran satisfactorily, vacuum engines never became practical. Sixty years later, during his work with combustion engines in the 1860s and 1870s, N. A. Otto (the inventor of the Otto cycle) reportedly used a synthetic gas of which Hydrogen content was more than 50%, as fuel. Otto also experimented mixing this gas with gasoline, but found it dangerous to work with, prompting him to return to using liquid fuels. Soon after, the development of the carburetor initiated a new era in which gasoline could be used both practically and safely, and interest in other fuels subsided. Liquid Hydrogen as stated above, remained a preferred fuel for rocket engines.

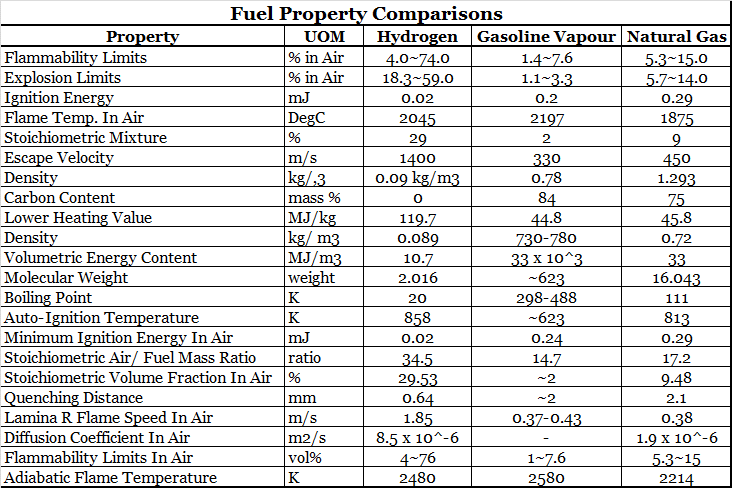

In recent years, the concern for cleaner air, along with stricter air pollution regulation and the desire to reduce the dependency on fossil fuels have reignited the interest in Hydrogen as a vehicular fuel. The properties that contribute to use of Hydrogen as a combustible fuel in ICEs are its wide range of flammability, low ignition energy, small quenching distance, as well as its high auto-ignition temperature, high flame speed at stoichiometric ratios, high diffusivity and very low density. Due to this wide flammability range hydrogen injected fuel-air mixture can be combusted in an ICE even when the fuel mixture is lean (i.e. it has lesser fuel than the theoretical, stoichiometric value). That’s why it is fairly easy to start an ICE on Hydrogen and also it gives a better fuel economy due to better combustion reaction when a vehicle runs on such a lean mixture. Additionally, with the usage of Hydrogen, the final combustion temperature is generally lower, reducing the amount of pollutants, such as nitrogen oxides, emitted in the exhaust. However, there is a limit to how lean the ICE can be run, as lean operation significantly reduces the power output due to reduction in the volumetric heating value of the air/fuel mixture.

Another advantage of using Hydrogen in ICE is that it brings down the ignition energy enabling these modified HICEs to ignite even the lean mixtures, ensuring prompt ignition. Unfortunately, this low ignition energy Hydrogen mixed fuel has a flip side, since even the hot gases and hot spots on the cylinder can cause premature ignition and flashback. Preventing this premature ignition is one of the challenges associated with running an engine on Hydrogen. The wide flammability range of Hydrogen means that almost any mixture can be ignited by a hot spot.

Hydrogen has a much smaller quenching distance than gasoline, which means Hydrogen flames will travel closer to the cylinder wall before they extinguish making it comparatively difficult to quench a Hydrogen flame than a gasoline flame within the engine. Such a smaller quenching distance can also increase the tendency for backfire since the flames from a Hydrogen-air mixture can more readily reach nearer to the closed intake valve, than a hydrocarbon-air flame. Yet with its relatively high auto-ignition temperature, the HICEs can be designed to have a much higher compression ratio than is being used for hydrocarbon ICEs.

Apart from these, with the very high diffusivity rate, Hydrogen is somewhat advantageous when used in ICEs for two main reasons – firstly, it facilitates the formation of a uniform mixture of fuel and air & secondly, if a Hydrogen leak develops, the Hydrogen disperses rapidly.

Thus, unsafe conditions can either be avoided or minimized. Not but least, Hydrogen has a very low density which results in two more problems when used in an ICE – firstly, very large volume storage of Hydrogen is necessary for an adequate driving range & secondly, due to the lower energy density of a Hydrogen-air mixture, the power output of ICE is reduced.

Despite all these challenges, trials to run conventional ICEVs to run on Hydrogen fuel were never stopped. However, Hydrogen can also be used Hydrogen fueled ICE which has higher reliability and cost performance and requires less investment for mass production than fuel cell vehicles.

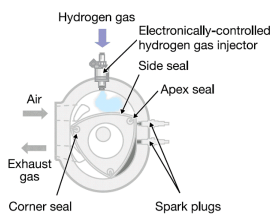

Rotary engine (RE) better known as “Wankel Engines”, provide merits such as prevention of pre-ignition of Hydrogen combustion. Mazda has been developing Hydrogen vehicles driven by Hydrogen ICE since the early 1990s.

| “Reciprocating” HIC Engine | “Rotary” Wankel HIC Engine | |

|  | |

| BMW With Reciprocating HICE | Mazda RS-8 with Rotary HICE | |

|  | |

Safeties Issues In Handling Hydrogen

Hydrogen, molecule is the smallest molecule (120 pm i.e. 120*10^-12 m) and hence has the greatest tendency to escape through openings. This tendency is about 1.26~2.80 times faster than a natural gas leak through the holes or joints of low-pressure pipelines however, since Hydrogen has about 1/3rd the energy density, than natural gas, any Hydrogen leak would result in much less energy release than a natural gas leak. For very large leaks from high-pressure storage tanks, where the leak rate is limited by the sonic speed, Hydrogen would escape 3 times faster than natural gas (due to the higher sonic speed in Hydrogen which is ~1308 m/s compared to the sonic speed in natural gas which is ~450 m/s). Another good property of Hydrogen is its buoyancy and rapid diffusiveness (compared to gasoline, propane, or natural gas) due to which in any untoward incident, of its leak for whatever reason, it will disperse much faster than any other gaseous fuel, thus reducing the hazard levels associated with Hydrogen.

Though the Hydrogen per is not corrosive, it can assist in the propagation of corrosion fatigue cracks and can also cause sulphide stress corrosion cracking in ferritic and martensitic steels, including the stainless grades. This is called Hydrogen embrittlement, also known as Hydrogen-assisted cracking or Hydrogen-induced cracking, is a reduction in the ductility of a metal due to absorbed Hydrogen since the Hydrogen atoms are small and can permeate solid metals. Thus Bulk Hydrogen storage also needs vessel made of specially treated high-strength steel as regular steel.

Hydrogen flames have low radiant heat because its combustion primarily produces heat and water. Due to the absence of carbon and the presence of heat-absorbing water vapor which is created when Hydrogen burns, a Hydrogen fire has significantly less radiant heat compared to a hydrocarbon fire. Since the flame emits low levels of heat near the flame (the flame itself is just as hot), the risk of secondary fires is lower. This fact has a significant impact on the public and rescue workers.

Like any flammable fuel, Hydrogen can combust. But Hydrogen’s buoyancy, diffusivity, and small molecular size make it difficult to contain and create a combustible situation. In order for a Hydrogen fire to occur, an adequate concentration of Hydrogen, the presence of an ignition source, and the right amount of oxidizer (like oxygen) must be present at the same time. Hydrogen has a wide flammability range (4~74% in air) and the energy required to ignite Hydrogen (0.02mJ) can be very low. However, at low concentrations (below 10%) the energy required to ignite Hydrogen is high – similar to the energy required to ignite natural gas and gasoline in their respective flammability ranges – making Hydrogen realistically more difficult to ignite near the lower flammability limit. On the other hand, if conditions exist where the Hydrogen concentration increased toward the stoichiometric (most easily ignited) mixture of 29% hydro-gen (in air), the ignition energy drops to about one-fifteenth of that required to ignite natural gas (or one tenth for gasoline).

The good part of Hydrogen storage is that no explosion can occur in its tank at any contained location without an oxidizer (i.e. oxygen) which must be present with a certain level of concentration (at least 10% pure oxygen or 41% air). Hydrogen can be explosive at concentrations of 18.3%~59% and although the range is wide, it is important to remember that gasoline can present a more dangerous potential than Hydrogen since the potential for explosion occurs with gasoline at much lower concentrations, 1.1%~3.3%. Furthermore, there is very little likelihood that Hydrogen will explode in open air, due to its tendency to rise quickly. This is the opposite of what we find for heavier gases such as propane or gasoline fumes, which hover near the ground, creating a greater danger of explosion.

With the exception of oxygen, any gas can cause asphyxiation. In most scenarios, Hydrogen’s buoyancy and diffusivity make Hydrogen unlikely to be confined where asphyxiation might occur. Hydrogen is non-toxic and non-poisonous. It will not contaminate groundwater (it’s a gas under normal atmospheric conditions), nor will a release of Hydrogen contribute to atmospheric pollution. Hydrogen does not create “fumes.”

Hydrogen has a flame velocity which is seven times faster than that of natural gas or gasoline but the detonation of Hydrogen in the open atmosphere is highly unlikely, because of its higher stoichiometric ratio of 29.53% against a value of 2% for Gasoline vapors & 9.46% Natural Gas). In order to explode, Hydrogen would first have to get accumulated to reach a minimum of 13% concentration level in a closed space and only then an ignition source, if triggered, can cause an explosion. Should an explosion occur, Hydrogen has the lowest explosive energy per unit stored volume, and a given volume of Hydrogen would have 22 times less explosive energy than the same volume filled with gasoline vapor.

Epilogue

Pure Hydrogen in nature exists as a H2 molecule in gaseous form which is a highly combustible diatomic gas.

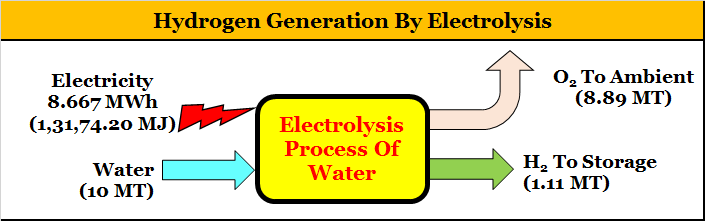

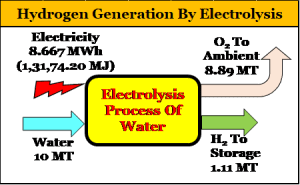

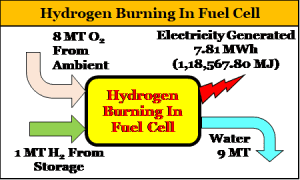

The enthalpy of the H-H bond in H2 (436 kJ/mol) is huge, much larger than the respective values for the molecules Li2 (110.2 kJ/mol) and Cl2 (242.6 kJ/mol), and rather close to that of the strongly bound O2 molecule (498.4 kJ/mol), thus extracting the Hydrogen by electrolysis process requires a large amount of electricity yet on reverse side, the burning of Hydrogen gas (in fuel cell) also releases an similar amount of energy as shown below.

The enthalpy of the H-H bond in H2 (436 kJ/mol) is huge, much larger than the respective values for the molecules Li2 (110.2 kJ/mol) and Cl2 (242.6 kJ/mol), and rather close to that of the strongly bound O2 molecule (498.4 kJ/mol), thus extracting the Hydrogen by electrolysis process requires a large amount of electricity yet on reverse side, the burning of Hydrogen gas (in fuel cell) also releases an similar amount of energy as shown below.

The energy in 1 kilogram of Hydrogen gas is about the same as the energy in 2.91 kilograms of gasoline (Considering the Avg Calorific values of Hydrogen as 142.50 MJ/kg vs. 49 MJ/kg of Gasoline), which is about 3 times more, however since the Hydrogen has a low volumetric energy density, it needs to be stored onboard a vehicle as a compressed gas to achieve the driving range of vehicles. However, considering the cost comparison it must be kept in mind that the 1 liter of Petrol contains about 30 MJ of energy which at present rate costs about Rs. 100, to obtain same energy approximately 126.50 (=30,000,000/237,160) moles of Hydrogen gas must be burned.

The weight of 126.50 moles of Hydrogen is about 253 grams – the cost of which must be less than or at least equal to Rs. 100 for its economic viability, which in turn means that the price of Hydrogen must be approximately Rs. 39.53 per kg. Unfortunately, as per he estimates of KPMG for India, the current cost of green Hydrogen production is in anywhere between ₹320 and ₹330 per kg (which is expected to fall in the range of about ₹160-170 per kg by 2030) while the cost of grey Hydrogen is about ₹160-200 per kg. This cost comparison makes if very apparent that though the Hydrogen is a “dream” energy source because of, first its highest combustion energy release per unit of its weight compared to any commonly occurring fuel; second, its reaction product is pure water. These two properties make it the ideal fuel of choice, however, it is not easy to organize the Hydrogen fuel infrastructure. There are numerous obstacles which needs to be scaled up before Hydrogen could be produced in bulk and made as affordable, convenient alternative to either the present day hydrocarbon fuels powering ICEVs or the electricity powering the upcoming EVs.

Lastly, always remember no energy can be said to be 100% green if evaluated over its complete life cycle as even to harvest, store, & distribute the greenest energy, mankind needs means & methods, many of which can surely, not be created by 100% green mechanisms and also the second law of thermodynamics prevails.

Read More: Is Hydrogen Fuel Cells will Replace Batteries in Electric Vehicles?

References:

- Handbook of Hydrogen Energy by S A Sherif & Others

- Hydrocarbon Fuels_ Production, Properties and Performance of Liquids and Gases by E M Goodger

- Hydrogen Handbook AH2 (2022) (Research Paper by John Hirjee)

- Hydrogen Energy for Beginners by Alexander Gavrilyuk

- Global Hydrogen Review 2021 by International Energy Agency

- The Hydrogen Hype: Gas Industry Fairy Tale Or Climate Horror Story? By Frans Timmermans

- Hydrogen Fuel – Production Transportation & Storage Edited by Ram B Gupta

- Hydrogen Storage and Technologies Edited By Mehmet Sankir

- Paper: Hydrogen Fuel Cell Engines and Related Technologies: Rev 0, December 2001

- Harnessing Green Hydrogen Opportunities For Deep Decarbonisation In India by Report by NITI Aayog (2022)

- Hydrogen: A Renewable Energy Perspective September 2019 Report Prepared For The 2nd Hydrogen Energy Ministerial Meeting In Tokyo, Japan (IRENA)

- Hydrogen Production And Storage: R&D Priorities and Gaps (IEA)