Typically, a standard EV Battery pack consists of hundreds, even thousands, of individual cells which are connected in series and parallel. It is to deliver the necessary power and capacity. There is a growing need for the manufacturing of battery packs to meet the demand reflecting the growth of these vehicles.

Typically, a standard EV Battery pack consists of hundreds, even thousands, of individual cells which are connected in series and parallel. It is to deliver the necessary power and capacity. There is a growing need for the manufacturing of battery packs to meet the demand reflecting the growth of these vehicles.

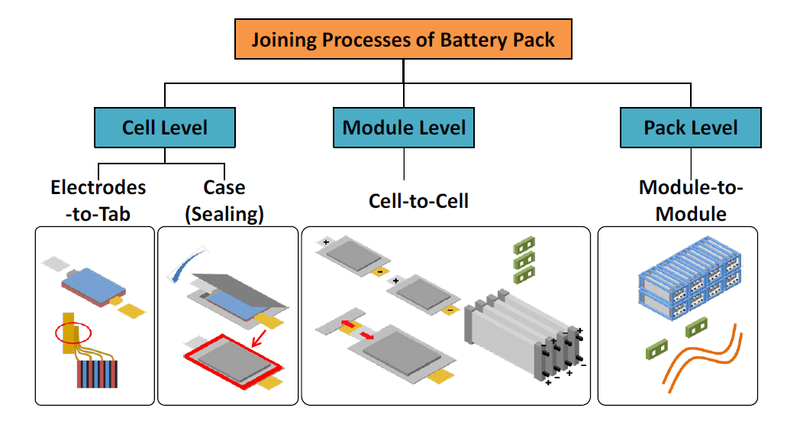

To deliver power and driving range, a large number of cells have to be connected by appropriate joining techniques. For example, in a pouch cell-based battery module, cell-to-cell electrical interconnects are achieved with tab-to-tab or tab-to-busbar joints.

Making these tab joints involves several challenges, including:

- Joining of multiple, thin, dissimilar materials of varying thicknesses,

- highly conductive and reflective surfaces,

- potential damage (thermal, mechanical, or vibrational) during joining

- joint durability.

Hence, there is a need for suitable joining techniques to support diverse joining requirements during battery pack manufacture.

Table of Contents

Welding methods for electric Vehicle for battery systems

Content:

- Assembly Levels Of Li-Ion Battery Pack

- RESISTANCE SPOT WELDING (RSW)

- LASER BEAM WELDING (LBW)

- ULTRASONIC WELDING (UW)

- Challenges Faced by The Welding Joints

- Welding Techniques With Advantages & Disadvantages

Assembly Levels Of Li-Ion Battery Pack

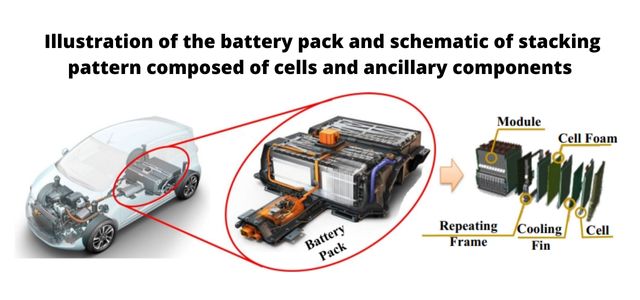

The design and Construction of a Li-ion battery pack for an Electric Vehicle require Robust and Reliable Joints on all levels as per sequence (Cell-Module-Pack).

- Cell Level

- Module Level

- Pack Level

Ultrasonic welding (UW), Laser Beam Welding (LBW), and Resistance Spot Welding (RSW) are the commonly used joining techniques for Li-Ion battery cells, modules, and packs.

RESISTANCE SPOT WELDING (RSW):

RSW works on the principle of…

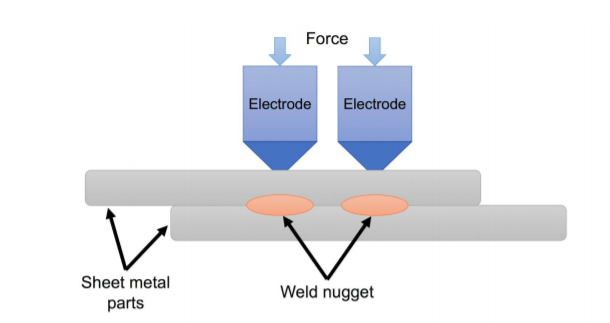

Electrical Resistance at the mating surfaces…When High Current passes through them, creating localized heating and Fusion of material happens under Pressure.  It is one of the oldest welding methods. It is a widely used manufacturing process for joining sheet metals. RSW is a technique where two or more metal sheets are welded together through the application of an electrical current and pressure between two electrodes. The electrical resistance of the material at the interface results in the generation of heat and melts the materials together without the use of filler material or gases. When welding with batteries, stray currents may arise from the battery.

It is one of the oldest welding methods. It is a widely used manufacturing process for joining sheet metals. RSW is a technique where two or more metal sheets are welded together through the application of an electrical current and pressure between two electrodes. The electrical resistance of the material at the interface results in the generation of heat and melts the materials together without the use of filler material or gases. When welding with batteries, stray currents may arise from the battery.

This current prevents the applied current and therefore it must be accounted for with a higher applied initial current. Too high applied current may however lead to electrode sticking.

The method typically uses a Dual pulse. The first pulse eliminates contaminations and oxides, and the second pulse welds the workpieces together. The temperature increases in the affected area, the interface, and eventually reaches the material’s melting point. A weld nugget forms in the affected area after cooling.

This is a small volume of the material which has melted and then fused. A schematic Figure is shown of RSW.

LASER BEAM WELDING (LBW):

LBW uses… A Focused Beam of Laser as a point energy source to create localized heating to join parts together.

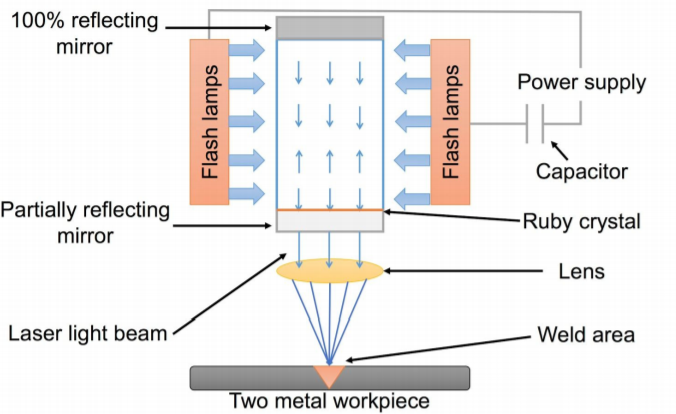

Laser beam welding or LBW is a welding technique in which a laser beam provides a concentrated heat source that fuses the materials. A lasing medium, a lasing cavity, and a pumping source are all primary components in a laser welding machine as shown in the schematic Figure.

Laser beam welding or LBW is a welding technique in which a laser beam provides a concentrated heat source that fuses the materials. A lasing medium, a lasing cavity, and a pumping source are all primary components in a laser welding machine as shown in the schematic Figure.

The design of the cavity determines the form of the outgoing beam and reflective lenses are used to focus the laser. The quality of the beam that is produced can vary and when welding, a beam with little diffraction is desired to create a concentrated heat source with small spot size.

ULTRASONIC WELDING (UW):

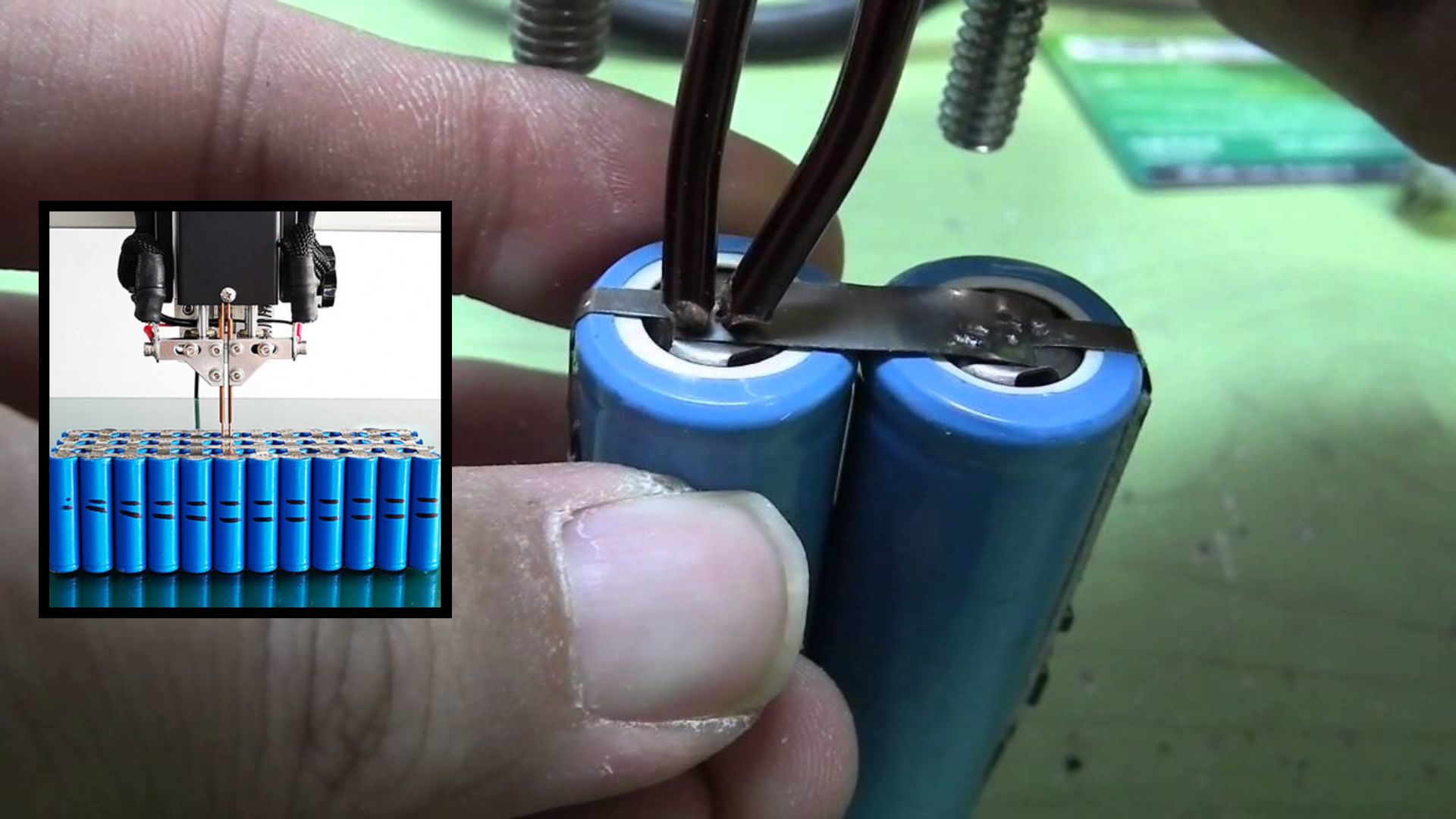

It is one of the most commonly used welding methods in the manufacturing of battery systems. It utilizes High-Frequency Ultrasonic Vibration (20kHz or above), to join substrate materials by creating solid-state bonds under clamping pressure.

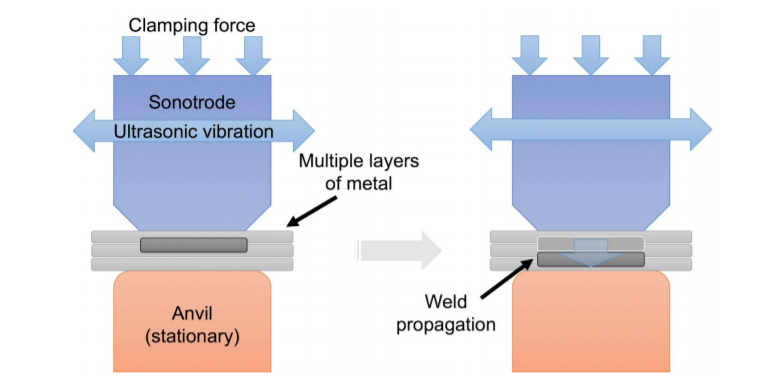

Ultrasonic Metal Welding or UMW, is a solid-state welding technique that forms a bond by applying moderate static pressure and an ultrasonic oscillation of about 20 kHz between two parts of metal, as seen in the Schematic Figure.

The solid-state weld is formed through the high-frequency motion between the parts causing continuous shearing and plastic deformation, while also removing any oxide layers or contaminants. The complete bonding mechanism is not fully understood, but some combination of metal interlocking, micro melting as well as metallic and chemical bonding is believed to help in the creation of the bond.

Read more: Cost of Lithium-ion Battery Manufacturing Plant & Machinery

Most metals can be ultrasonically welded and the method is excellent for welding together thin foils, as well as thicker sheets with spot or seam welds and also wires.

Challenges Faced by The Welding Joints are:

| No. | Category | Challenge |

| 1 | Electrical and Thermal |

|

| 2 | Material and Metallurgical |

|

| 3 | Mechanical |

|

Welding Techniques With Advantages & Disadvantages:

1) Resistance Spot Welding

Advantages

- Low initial cost

- Can weld thin sheets

- Easy to automate and good for production • Good quality control

Disadvantages

- Difficult welding highly conductive material • Difficult to produce large nuggets

- Difficult welding multiple layers

- Electrode sticking

2) Laser Beam Welding

Advantages

- Non-contact process

- High precision of the welding

- Good for mass production

- The relatively small heat-affected zone

Disadvantages

- High initial cost

- Material reflectivity

- Needs a good joint fit-up

- Harder to weld dissimilar materials together

3) Ultrasonic Welding

Advantages

- No or minimal metallurgical defects

- Excellent for joining dissimilar metals

- Most metals, even highly conductive can be welded

- Low-temperature increase and low energy input

Disadvantages

- For UMW two-sided access is needed

- UMW is primarily suitable for the pouch and prismatic cells

- May cause structural damages to battery cell if fixated improperly

- Sensitive to high surface roughness

Conclusion:

When putting all the points together, the welding technique which can weld dissimilar material better, with minimum defects, and can weld highly conductive material together, is Ultrasonic Welding.

Dear Sir/ma’am, I am Mukul Kumar, am interested to apply of this company .Below are my details, please let me know if I can attend the interview for the job. Name – Mukul Kumar ,Qualification – Graduate (B.Tech) , Hope to hear from you soon! And this is my resume. Thank you

Good job Dhenuka, keep it up…!!💐

Thank you Mihir😊

Great job Dhenuka, keep going…!!🙌🏻

Well documented.

Thank you

Research Done Well!!!

Thank you😊

The way you handled the project showed resilience, experience, knowledge, and critical thinking , excellent work.

Thank you so much for the wonderful feedback :))

Good job done..

Thank you!

Well done

So much of valuable info at one page. Definitely a solid work. I will keep revisiting for learning.

Thank you for the feedback Mr.Puneet!

Good artical about battrev.vomminh time isfor two-wheeler battery

Thank you Very Very Much😊

Dear Dhenuka, Excellent job… Keep it up… You are clever and wise daughter… Best of luck for your future job and work… 👍👌👍

Thanks a Lot Bhatt Uncle!!!

It is a great feeling as a writer and an energetic response from you😊

It’s a Brilliant Class article by Dhenuka Mahant about EV Battery Welding Technologies, which will be so enhancing for the welding necessities especially in automobile machineries. The content of the article is rudimental to the basics of the technology. The elaboration of the topics is superb and class apart. The language and sentences employed in the description is absolutely a State of the Art. Many many Congratulations to Dhenuka. Wish to have a great future ahead.

Thank You So So Much!!! Mr.Jay Amin

It feels so Good to know that Readers like you acknowledge the research of the Content!!!😊

Thanks a lot for your Valuable Feedback!!!

Great Job..

Thank you!

Great work Dhenuka

Thank you!

Thanks!

Great work Dhenuka….. 👍🏻

Carry on….

Thank you ☺️

Good job dhenuka well done

Thank you!

It’s very informative content. My many doubts are cleared here.

Thank you for sharing your knowledge.

Thank you for the Feedback!

Very well explained

Thank you!

Good job nd congratulations for new technology update

Thank you!

Two-wheel,battery,is,coming,time,good fuel,sogo ahead,and aheaf

Thank you!!!🙏🏻

Happy,congratulation

Thank you ☺️

My sister,dhenuka mahant,has,done best research,aboute-battery,congrats,u9

Thank you ☺️

Yrdada,from,Chicago,u.s.a.gives u lot of blessing new inno action work&representation that will be,next age petrol.go ahead and ahead

Thanks a lot 😊

Hi Dhenuka,

Are you familiar with Closed Loop Control techniques for ultrasonic metal welding?