The Indian automobile sector is one of the most prominent sectors in the country, accounting for about 7.1% of the national GDP. The Indian Lithium-ion battery market is expected to grow at a robust CAGR of 29.26% during the forecast period, 2018-2023.

This facilitates the development of new technologies and ensures a high-quality product.

Here in this article, the cost of a lithium-ion battery manufacturing plant and the types of machinery used in manufacturing a lithium-ion battery.

Cost of Lithium-ion Battery Manufacturing Plant & Machinery

An Introduction

Lithium-ion batteries have become the most critical applications of lithium and storage technology in the fields of portable and mobile applications (such as laptops, cell phones, smartphones, tablets, laptops, power Banks, And Electric Vehicles like Electric Bicycle, Electric bikes, electric scooters, electric cars, and electric bus).

Lithium-ion (Li-ion) batteries are rechargeable batteries with high energy density and are majorly used in portable devices.

The market for these batteries is expected to grow significantly due to the increase in the usage of smartphones, tablets/PCs, digital cameras, and Electronic gadgets.

Read More: Tips to keep Lithium-ion Battery Safe for long life

Furthermore, the demand for Li-ion batteries in the automobile industry is expected to grow in line with the growing demand for electric vehicles. These batteries have gained popularity among automobile manufacturers as they offer an alternative to nickel-metal batteries used in electric vehicles due to their smaller size and lighter weight.

Since lithium-ion batteries have different uses, it comes in a variety of packaging. However, there are some general advantages to using Li-ion batteries over other conventional batteries.

Advantages of Lithium-Ion Batteries

Following are some of the Advantages of Lithium-ion Batters

- High Energy Density

- Low Self Discharge

- No Requirement for Priming

- Low Maintenance

- A variety of types are available

Lithium-Ion Batteries Global Market Outlook

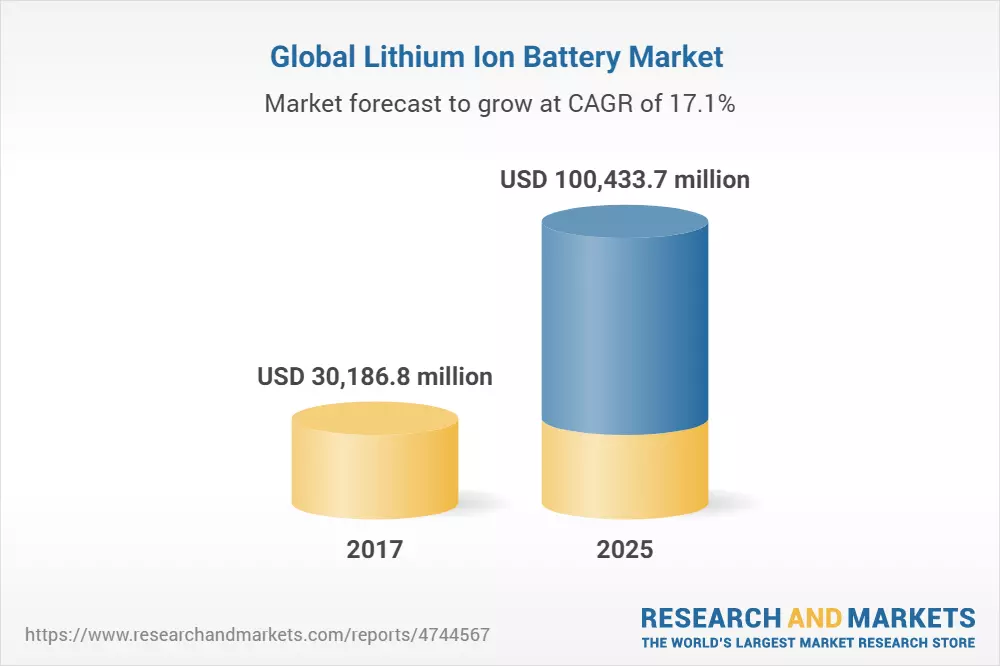

Image Source: www.researchandmarkets.com

The global lithium-ion battery market was valued at $30,186.8 million in 2017 and is projected to reach $100,433.7 million by 2025, growing at a CAGR of 17.1% from 2018 to 2025. (1)

The growing automotive industry is also an important factor contributing to the growth of the market. most likely to increase

Coming from emerging markets due to increasing population, rapid urbanization, and purchasing power.

Some of the key players operating in the global lithium-ion battery market include

- Automotive Energy Supply Corporation

- Panasonic Corporation

- Samsung SDI Co. Ltd.

- LG Chem Power (LGCPI), LITEC Co.Ltd.

- A123 Systems, LLC.

- Toshiba Corporation,

- Hitachi Chemical Co. Ltd.

- China BAK Battery Co. Ltd.

- and, GS Yuasa International Ltd.

Read More: Top Lithium-ion Battery Manufacturers

Lithium-Ion Battery Market India

The Indian automobile sector is one of the most prominent sectors of

the country accounts for about 7.1% of the national GDP.

However, India has set an ambitious target of having electric vehicles (EVs) only by 2030, which is expected to drive a significant increase in the demand for lithium-ion batteries in India.

The high cost associated with the batteries used in electric vehicles is seen as a key to India’s ambitious goal. The Indian Lithium-Ion Battery Market is expected to grow at a strong CAGR of 29.26% during the forecast period, 2018-2023.

Top Players in the Indian Lithium-ion Battery Market

Some of the key players operating in the Indian lithium-ion battery market include

Major companies operating in the Indian lithium-Ion battery market are

- Samsung SDI Co. Ltd.

- Panasonic Corporation

- Toshiba Corporation

- Hitachi Chemical Co., Ltd.

- China BAK Battery Co. Ltd.

- Amara Raja Batteries Ltd

- Exide Industries (Storage Battery manufacturing Company)

Lithium-ion Battery Manufacturing Plant Cost

| [Project at a Glance] | Cost of Project | ||

| Particulars | Existing | Proposed | Total |

| Land & Site Development Exp. | 0.00 | 210.00 | 210.00 |

| Buildings | 0.00 | 160.50 | 160.50 |

| Plant & types of machinery | 0.00 | 90.50 | 90.50 |

| Motor Vehicles | 0.00 | 12.00 | 12.00 |

| Office Automation Types of equipment | 0.00 | 40.50 | 40.50 |

| Technical Knowhow Fees & Exp. | 0.00 | 2.50 | 2.50 |

| Franchise & Other Deposits | 0.00 | 0.00 | 0.00 |

| Preliminary& Preoperative Exp | 5.00 | 5.00 | |

| Provision for Contingencies | 0.00 | 7.00 | 7.00 |

| Margin Money – Working Capital | 0.00 | 548.37 | 548.37 |

| TOTAL | 0.00 | 1076.37 | 1076.37 Lakhs |

Cost of Lithium-ion Battery Manufacturing Plant

| Plant & machinery Total Cost: | Rs 90 lakhs |

| T.C.I Cost of Project | Rs 1076 lakhs |

| Plant capacity: 90 Volt, 180 Ah Lithium-Ion Battery Pack | 56 Nos/day |

| Return | 34.00% |

Lithium-ion Battery Manufacturing Machinery and Equipment

Types of machinery for the manufacturer of all types of lithium-ion batteries are similar;

Tab Welding Bench

This machine welds a tab or lug on each electrode for an electrical connection. It is composed of: an equipment frame; tab roll un-winder; 40 kHz ultrasonic welding Unit: and a frame with alignment/ safety enclosures.

The lugs are welded on the cleaned aluminum where the active material is removed. The tabs are made of nickel-coated steel.

Cells Winding Machine

The main function of this machis is to wind the pre-cut tabbed anode and cathode electrodes as in the above separator layers for interlacing between them. Separators are unwound from rolls. Electrode placement is made precise with a tensioning system and positioning of sensors for the pre-cut electrode. A large graphic human-machine interface (HMI) provides all information and setting adjustments.

The machine is composed of an equipment frame; 2 separator roll unwinding spools; 2 electrode feeding plates with tensioning grippers; And 2 electrode insertion grippers on the winding turret; one cylindrical winding mandrel; automatic cells tapping system; safety guards, electrical cabinet, and HMI graphics display.

DEEP CAN Welding Machine

The machine is used to carry our resistance welding of the anode tab to the bottom of the can.

CAN Necking Machine

This machine carves the groove to accommodate the Cell’s Top Cap

Top cap Welding machine

This machine joins the aluminum positive tab to the Cell’s top cap by Ultrasonic welding

Electrolyte Filling Machine

The Electrolyte Filling machine is critical equipment to fill the cylindrical cell with electrolytes under vacuum conditions. Since the volume of electrolytes is only 2-3 ml per cell with very close tolerances, accuracy becomes very important. The filling is done after evacuating the cell.

Can Crimping Machine

Can crimping machine is used to crimp the top cap on the can’s top

Welding of Safety Devices

A Nickel-plated steel strip with the safety sensor on top is welded by resistance welding. This item is to be imported along with other items like cans.

Machinery for Manufacturing Pouched Cells Battery

Following additional machinery is required to make pouched cells Battery. The pouched cells have rectangular; electrodes and are assembled in a pouch with separators.

This is similar to lead-acid battery cells assembled as a group-housed in a container.

Electrode Punching Machine

The electrode punching machine punches the electrodes from a coated roll in an automatic process which reduces the workforce needed for its operation.

The tolerance on the cutting tool ( in the micron range) allows a precise cut without burrs and with constant dimension.

Z-Fold Stacker

Z-fold stacker; this piece type of equipment creates cell stacks. The stacking of the anode, cathode, and separator is performed automatically with precision and repeatability.

The separator is unwound in front of the roll with tensioning and alignment controls, while electrodes are picked up from trays.

Tab welding & Trimming Machine

Tab Welding & Trimming Machine trim staked electrode current collectors and weld final tabs to the anode and cathode of the cell stack. During the welding phase, stack tabs are maintained in a specific tray for accurate positioning. It is provided with wheels for easier positioning and relocation inside the elaborate or dry room.

To weld larger cells or tabs, only the horn and anvil of the welding unit need to be replaced, and a dedicated tray needs to be adopted to the new stack and tab sizes.

Blister Forming Machine

The blister forming machine is designed for the production of single-cavity blister pouches for Li-ion cells from a roll of packing material.

Degassing and Sealing Machinery

Degassing and sealing machinery is primarily used for the first vacuum sealing of a pouch Li-ion battery. This is done after filling electrolytes in each pouch. Any gas that enters the electrolyte is removed by vacuum, then the pouch is sealed.

Read More: Recycling Process of Lithium-Ion Batteries