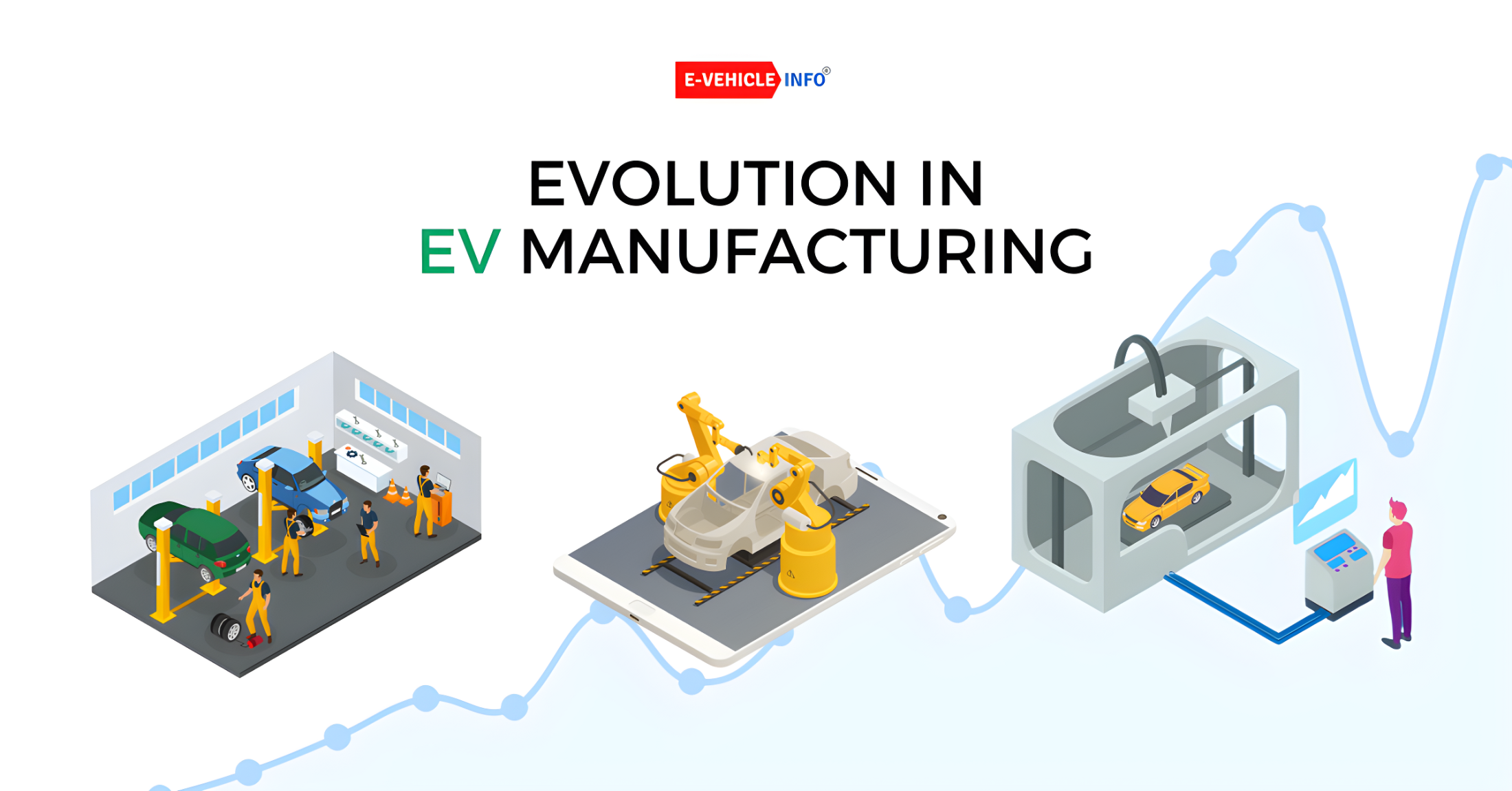

Despite the fact, that over the last 120 years of automobile manufacturing, all the processes of automobile manufacturing are more or less standardized, and probably, no major concept evolved after Henry Ford’s revolutionary ideas of “Moving Assembly Line” and “Interchangeability Of Parts” in early 1910, Citroën’s astonishing “Traction Avant ” of 1934 and later “JIT’ of Toyota in 1950s.

However, since their inception automobile manufacturing always had a great appetite for adopting new technologies yet there was a vacuum after 1950. So, when IT revolution came with cloud computing, big data analytics to advanced robotics/ cobotics for increasing productivity & efficiency while reducing human intervention in order to get competitive edge.

The automobile industry was the first one to jump into utilizing sophisticated technologies, such as AI (artificial intelligence), IoT (the internet of things), IIoT (industrial Internet of Things) and 3-D printing/ manufacturing amongst others, were shaping the future of manufacturing by lowering the cost of production, improving the speed of operations and minimizing errors.

Since productivity is most critical to the success of automotive manufacturing, every automobile manufacturer have made significant investments in these technologies.

Out the many of the newer IT enables technologies mentioned above, 3D printing/ manufacturing is the one which needs special attention with respect to automotive manufacturing while on a broader scale three other non IT related technologies are also gaining attention. These manufacturing technologies are related to hard core manufacturing practices, and cover

a) application of new age composite materials,

b) unibody casting of body shell,

c) “skateboard” chassis for future EVs

d) ADAS supporting manufacturing.

These are briefly explained below:

Table of Contents

1. 3D Printing/ Manufacturing

Despite being invented in 1980, 3D printing and manufacturing technology has only recently (as of 2020) reached a significant milestone. While it may not completely revolutionize the manufacturing industry in the near future, predictions indicate that by 2023, the global 3D printing market is likely to reach a market valuation of US$ 27.7 billion, accelerating with an impressive CAGR of 21% from 2023 to 2033.

The 3D printing market share is expected to value at about US$ 186.4 billion by 2033 end. This innovative technology has already proven its significance in design studios and factory settings alike, poised to revolutionize automotive manufacturing in the coming years. Serving as a cost-effective solution for prototyping, functional testing, vehicle customization, design optimization, and rapid tooling, 3D printing is becoming an indispensable tool for engineers across all stages of automotive manufacturing – from designing and prototyping to testing, mass production, tooling, and customization.

As more applications for 3D printing in manufacturing continue to be discovered, the automotive industry is just beginning to witness its transformative potential. Both automobile manufacturers and parts suppliers are swiftly adopting 3D printing to reduce costs, enhance efficiency and productivity, and minimize the time required for model changes and reconfiguring the automotive supply chain.

Notably, in 2014, in collaboration with Cincinnati Incorporated and Oak Ridge National Laboratory, Local Motors, a United States-based company, manufactured Strati, the world’s first 3D printed electric car. The printing took 44 hours to complete, and was witnessed by a live audience at the 2014 International Manufacturing Technology Show in McCormick Place, Chicago. The car consists of 50 individual parts, far less than an ICEV (which has roughly 30,000 parts). The Strati was designed by Michele Anoè, a member of the Local Motors community, and is produced in small quantities to serve strategic partnerships, such as with NXP Semiconductors.

2. Application of New Age Composite Materials

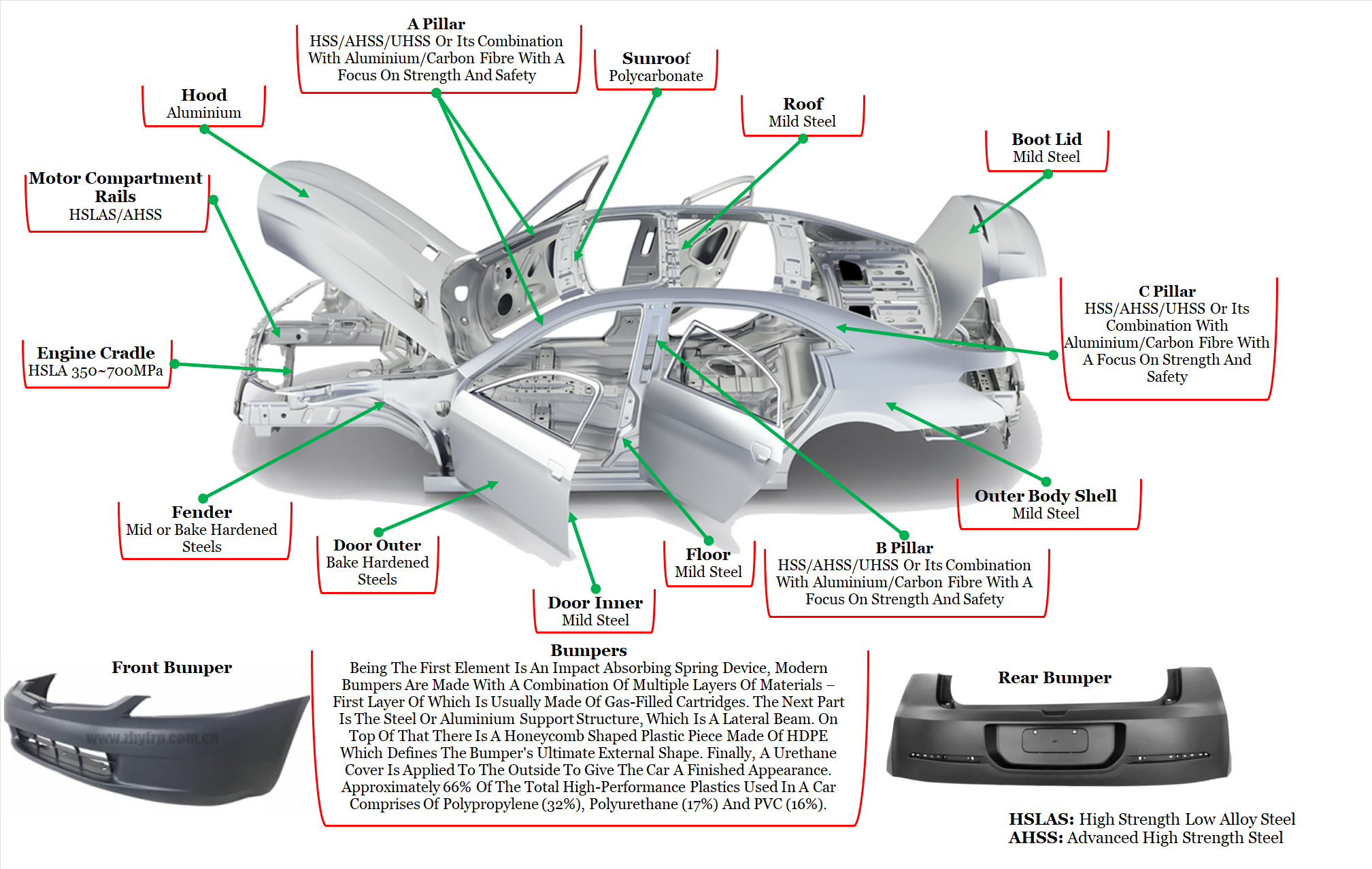

Most probably it all started in 1905 when Henry Ford is said to have discovered the vanadium steel alloy, which was not only lighter than ordinary steel but also almost three times stronger & used in his Model T which made it superior to all the other vehicles prevailing in automotive market of USA. From then onwards, automobile manufacturers have always been one of the very first to utilize any of these new-age materials to reshape the automobile manufacturing process as well as automobiles, themselves.

These continuously evolving new-age materials are also quite useful in creating complex and elaborate body shapes for the automobiles with least wastage and effort. The automotive industry is seeing a surge in demand for advanced materials due to the need for light weighting to meet higher fuel efficiency norms and extending battery range. Glass and carbon composites along with aluminum alloys are witnessing increasing demand for automotive component and body manufacturing.

The automotive industry is undergoing a crucial phase to address user and environmental concerns, focusing on the substantial challenge of reducing vehicle weight to enhance fuel efficiency. A projected 10% curb weight reduction could lead to a 6%-8% decrease in fuel consumption. In the pursuit of improving vehicle safety, noise control, and fuel economy, automakers continually introduce new materials, prioritizing light weighting without compromising safety.

While historical cars were predominantly steel-based, the industry is now shifting towards aluminum, the fastest-growing lightweight material, alongside magnesium and high-performance composite materials. Current vehicles maintain predominantly steel structures with some incorporation of aluminum. Steel grades vary from mild (270 megapascal tensile strength) to hot-formed boron (1,500 Mpa plus tensile strength).

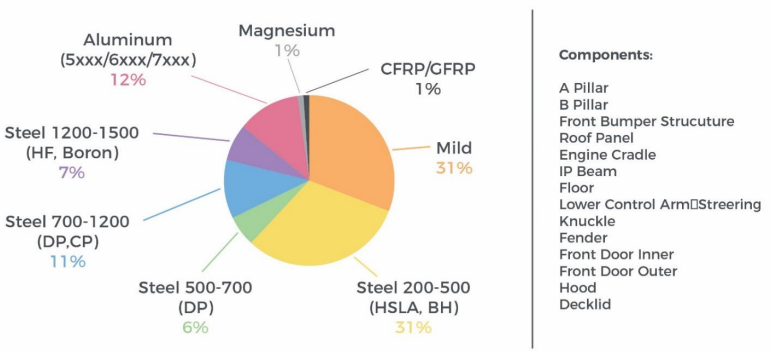

The Proportion Of Different Composites In An Automobile

Magnesium and polymer composites are increasingly finding newer applications, particularly in higher-end vehicles. The automotive lightweight materials market is anticipated to grow at a 7.4% CAGR from 2019 to 2027, projecting a market size increase from USD 89.1 billion in 2019 to USD 157.7 billion by 2027.

Presently, aluminum is favored by over three-fourths (82%) of assemblers, while other sought-after lightweight materials include plastics (53%), carbon-fiber composites (29%), high-strength steel (29%), and magnesium (11%). Given the current challenges faced by auto OEMs, the industry is anticipated to pivot towards alternative materials to reduce automobile weight for a more sustainable future.

OEMs are exploring composites as replacements for steel and aluminum due to their exceptional properties, being 10 times stronger than steel, 8 times stronger than aluminum, and significantly lighter than both. Some OEMs are also incorporating natural fiber-reinforced composites to reduce vehicle weight, employing materials like cellulose tree fibers in armrests and rice hulls and wheat to reinforce plastics and storage bins.

Hollow glass microspheres known as “glass bubbles” of 3M, made from water-resistant soda-lime borosilicate glass, reduce the composite weight by up to 40%. While “Coretinium” by Tata Steel has introduced an optimized polypropylene honeycomb core, for flooring and sidewalls in buses and trailers, currently used in the EU region for commercial vehicles. Chemical manufacturer SABIC has introduced a “fiber-reinforced thermoplastic composite bulkhead”, anticipating a 35% mass reduction compared to traditional metals. DSM Engineering Plastics developed “EcoPaXX PA 410”, a bio-based polyamide used in Volkswagen’s MDB-4 TDI diesel engines.

The Cadillac CT6 incorporates “carbon fiber-reinforced plastic (CFRP)” for lightweight body parts, ensuring high performance, fuel efficiency, and improved traction at high speeds. BASF, in collaboration with Magna and Ford, engineered a “carbon-fiber composite grill opening reinforcement”, utilized in the 2016 Ford Shelby GT350 Mustang, boasting a 24% weight reduction compared to traditional metal. Additionally, BASF’s “Acrodur”, a water-based, low-emission binder, strengthens natural fibers to create a sustainable, stable, and lightweight solution for car roof frames, exemplified in the Mercedes Benz E class.

3. Modularization In Automobile Manufacturing

A much bigger change in automotive manufacturing is expected in times to come when the present mobility system shifts from ICEVs to EVs (as of now the EVs have hardly 2.2% market share), since it would require shift in technology and thus the related manufacturing capabilities. A shift in which about 31% of the components and related manufacturing processes (IC engine, transmission, & lubrication & emission controls), will be phased out.

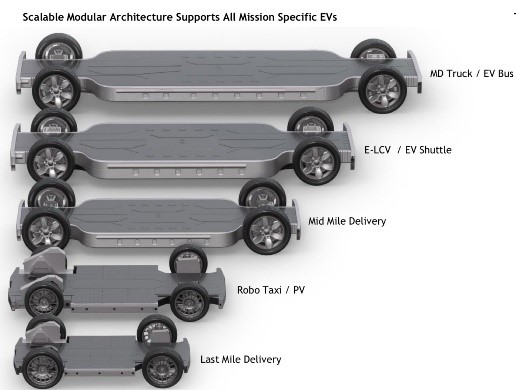

In the context of EVs, apart from present, age-old configuration, in which the IC engine is simply replaced with an electric drive under the hood, while the battery pack is mounted below the body, other models are also evolving e.g. an Israeli technology firm, REE Automotive is trying to remodel the very basic structure of EVs (both monocoque & ladder type chassis) and bringing an “skateboard” EV chassis. Their wheel units are called REEcorner which has a set of completely independent, integrating critical vehicle components (steering, braking, suspension, powertrain and controls) inbuilt into a single compact wheel module.

Scalable Modular Architecture of REECorners, Supporting Multiple EV Types

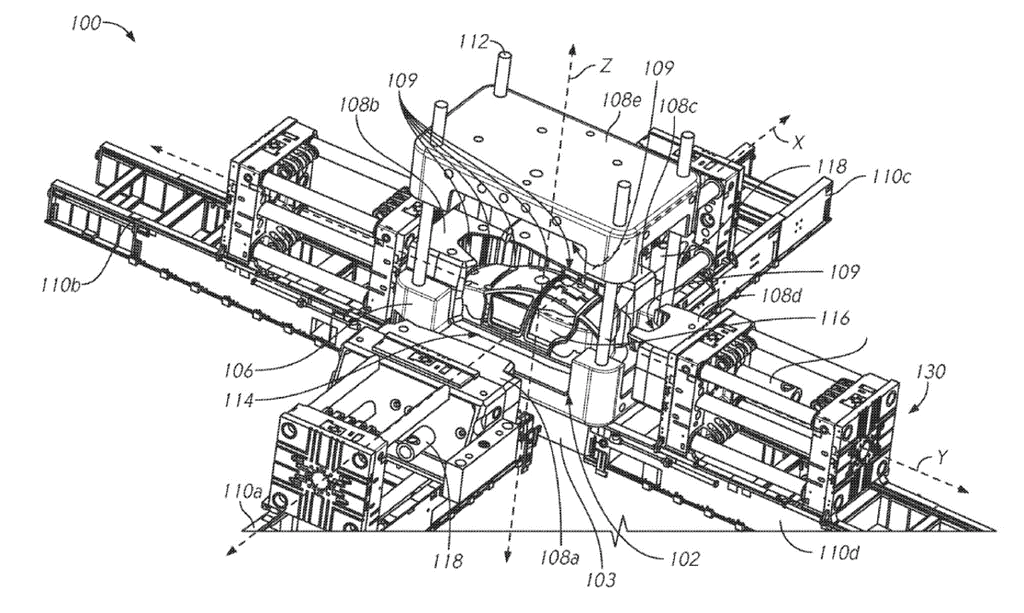

4. Unibody Casting of Body Shell

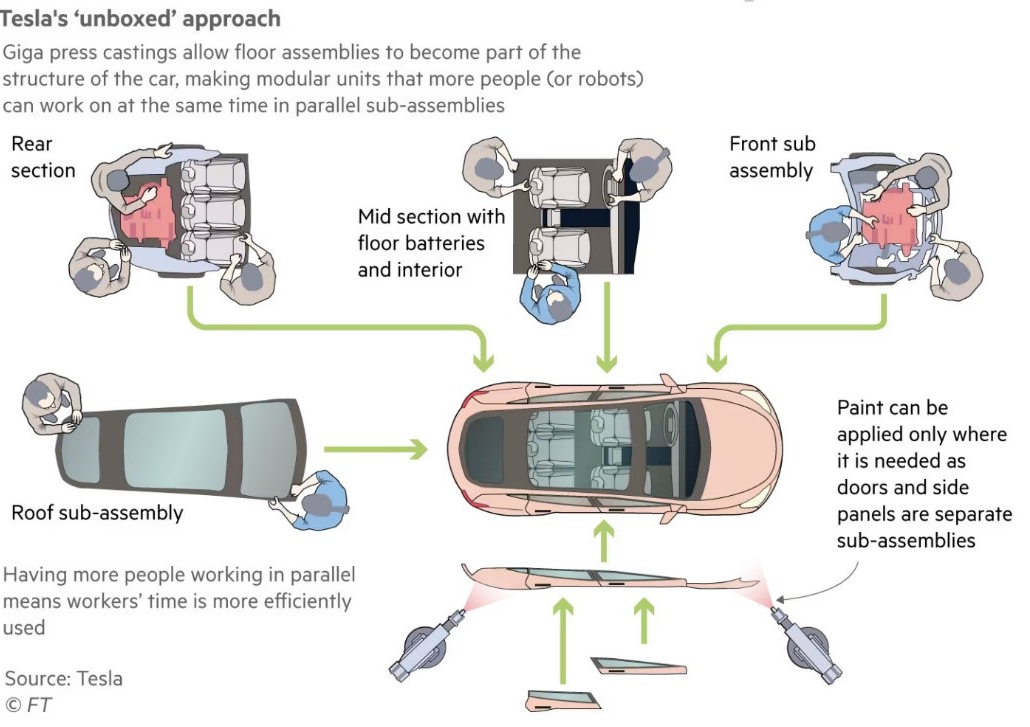

Giga Press In Real World Application |

| GIGAPRESS Going From 5500 To 9000 Tons And Counting Opens A New Era In Die-Casting ‘Giga’ Solutions. | Tesla’s Concept For A Giant Uni Casting Machine for Casting the Whole Car Body As Single Cast |

|  |

With such a machine, the production of the body can be much more economical, faster, and easier. According to information from the source, the production of this machine can reduce the time spent on car production by 25%. In addition, a 10% reduction in downtime is expected. As stated, when this new manufacturing process of Car shell (white body), becomes popular and proves its worth, and giant unibody casting machines is commercialized, it would eliminate more than 100s of intermediate processes in automobile manufacturing e.g. pressing & welding in sheet metals to create sub-assemblies which again are welded using multiple jigs & fixture to make final shell (white body). This is a technology, which has the possibility not only to eliminate many of the present intermediate processes in automobile manufacturing, it can also take the present automobile manufacturing to the next level. Elon Musk had also tweeted sometime back on these Giga presses, “With our giant casting machines, we are trying to make full-size cars in the same way that toy cars are made.”

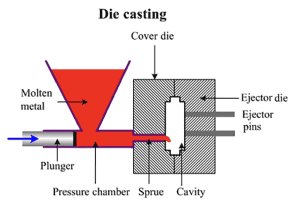

Die casting is a metal casting process which was invented sometime in 1838 for the purpose of producing movable type for the printing industry. The first die casting-related patent was granted in 1849 for a small hand-operated machine for the purpose of mechanized printing type production.

However, over the time, it has found many other applications and presently it used to create high-quality, durable parts for use in various applications. It is a process that allows the production of metal parts with a high degree of precision. In this casting process, molten metal is injected into a mould, where it cools and hardens to create the desired shape. The method can be used to create various metal parts, from gears and engine blocks to door handles and electrical components. Die casting process is well known for its ability to produce parts with a smooth surface finish and precise dimensions. In addition, this process is relatively fast and cost-effective, making it an attractive option for many applications.

Evolution Of Die Casting from The Toy Industry To Car Industry: Die-casting found its way in to toy making when in early 20th century manufacturers such as Meccano (Dinky Toys) in the United Kingdom, Dowst Brothers (TootsieToys) in the United States and Fonderie de précision de Nanterre (Solido) in France started molding scaled toys. The initial models were basic, consisting of a small vehicle body with no interior.

Read More: Gigacasting: How Transforming the Future of EV Manufacturing

In the early days, as mentioned, it was common for impurities in the alloy caused the castings either to distort, crack, or crumble. The later high-purity Zamak alloy avoided this problem. In 1947, Lesney began making die-cast (named “Matchbox” series), which became so popular that the “Matchbox” was widely used as a generic term for any die-cast toy car, regardless of manufacturer. The popularity of die-cast toys developed through the 1950s as their detail and quality increased.

More companies entered the field, including successful brands like Corgi brand, produced by Mettoy, Italian Mercury, Danish Tekno, or German Schuco and Gama Toys. Corgi Toys appeared in 1956 and pioneered the use of interiors and windows in their models. In 1968, Hot Wheels were introduced in the United States by Mattel & quickly became the most popular die-cast cars in the toy market, becoming one of the world’s top sellers, challenging the popularity of Matchbox. Since 2009, the Diecast Hall of Fame inducts designers, industry executives and others that have made major contributions to the industry.

Die Casting Process At Work: The die casting process involves several steps, including mould design, metal preparation, injection, casting, and finishing.

Step 1 – Mould design/ Die Design: usually made from steel or aluminum and is designed to withstand the high temperatures and pressures of the die casting process.

Step 2 – Metal Preparation: These metals are typically alloys, of aluminum, magnesium, or zinc. The metal is melted in a furnace and then poured into a ladle.

Step 3 – Injection Process: Once the metal is liquified, it is injected into the mould under high pressure. The molten metal fills the mould cavity and cools to create the desired shape.

Step 4 – Casting Process: After the metal has cooled and hardened, the mould is opened, and the part is ejected.

Step 5 – Finishing Process: The final step involves surface finishing which plays a vital role in die casting, as it can impact the durability and function of the part. Standard finishing processes include anodizing, powder coating, wet plating, and many more.

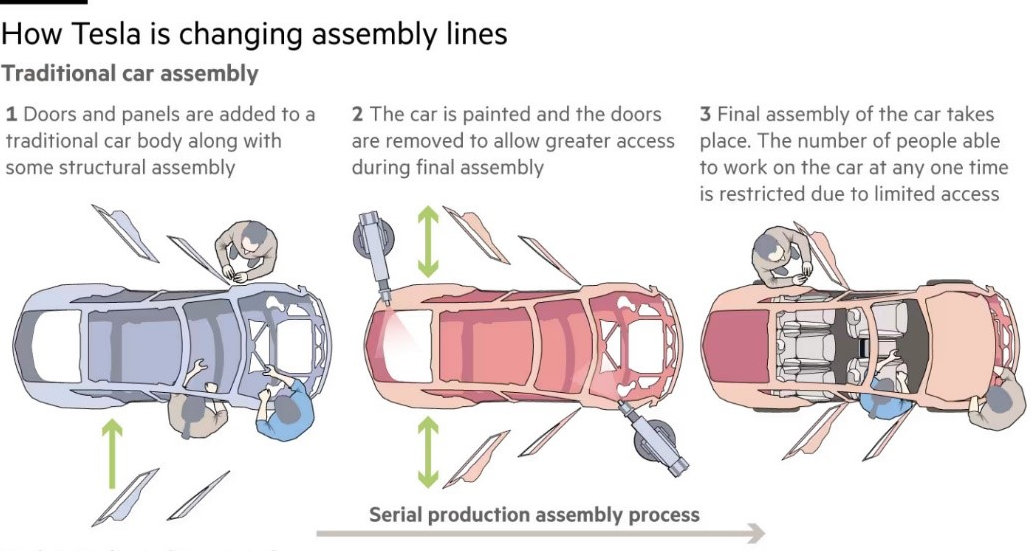

Traditional Car Assembly Process (Linear or Assembly Line) For ICEVs

5. ADAS Supporting Manufacturing:

Assisted Driving Systems (ADAS) signify a revolutionary IT technology gaining momentum within the automotive sector, enhancing road safety for both Electric Vehicles (EVs) and Internal Combustion Engine Vehicles (ICEVs). However, due to intricate complexities and legal considerations, the transition from the current rudimentary Levels 2 and 3 of ADAS to the cutting-edge Level 5 may necessitate several more years.

This evolution primarily entails a paradigm shift in connectivity and control technology, potentially not mandating significant alterations to the future of automobile manufacturing processes. Nevertheless, its impact is notably accentuated in EVs, capitalizing on the superior control and response capabilities of electrical systems in contrast to the electro-mechanical systems in ICEVs.

Looking forward, the arrival of Connected and Autonomous Electric Vehicles (CAEVs) is on the horizon. These vehicles will possess the ability to perceive, comprehend, and make decisions akin to human reasoning, and autonomously navigate roads. The manufacturing processes for these futuristic CAEVs are still in the nascent stages of development.

Unlike conventional automobile assembly, producing these intelligent and astute EVs, which involve intricate decision-making capabilities comparable to human cognition, will require a significantly advanced level of manufacturing, perhaps not fully realized yet—although glimpses can be seen in COBOT manufacturing, programming, and operation. Any manufacturing errors in this process could have profound and far-reaching consequences on our societal fabric.

Conclusion

As society transitions from current Internal Combustion Engine Vehicles (ICEVs) to Electric Vehicles (EVs) and anticipates the advent of Cutting-Edge Autonomous Electric Vehicles (CAEVs), the intricate evolution of technologies shaping future automobiles is set to revolutionize manufacturing processes. The merging of pivotal emerging manufacturing technologies, such as the Skateboard platform with its comprehensive single-wheel drive units and the die-casted Unibody shell, may redefine the landscape of automobile manufacturing or face challenges reminiscent of past endeavors.

The automotive industry is closely monitoring the integration of these technologies. Meanwhile, a report from PWC envisions the future of automobile manufacturing, highlighting key focuses on Electrical, Autonomous, Shared, Connected, and Yearly Updating (EASCY). The shift to EASCY poses a formidable challenge for current automotive industry leaders, as the transformation may eliminate established manufacturing processes while introducing novel ones. Original Equipment Manufacturers (OEMs) and their supply chains must navigate these uncertainties, preparing for unforeseen challenges in the emerging market. The rise of Electric Vehicles (EVs) signals the commencement of a survival-of-the-fittest battle in automotive manufacturing. As the industry undergoes this transformative phase, the outcome will reveal the survivors, their strategies, and approaches. Some may ultimately ascend to the ranks of automotive pioneers like Henry Ford and Toyota, guiding the next era of automotive manufacturing in the coming century once the dust settles in the years ahead.