It’s interesting to compare the battery in your phone with that in an electric vehicle and to look at our expectations of each.

Your phone will have a pouch cell with a capacity between 2.5Ah and 5Ah. It will operate between 4.2V when fully charged and stop around 2.9V when absolutely empty. You will probably keep it close to you so it will be at a happy 15°C to 45°C. The battery management system on the phone will monitor the temperature and voltage of the cell, thus allowing the charge and discharge to be optimized.

It will probably power your phone for nearly 2 days and you will want to charge it in 30 minutes just before you go out to meet friends.

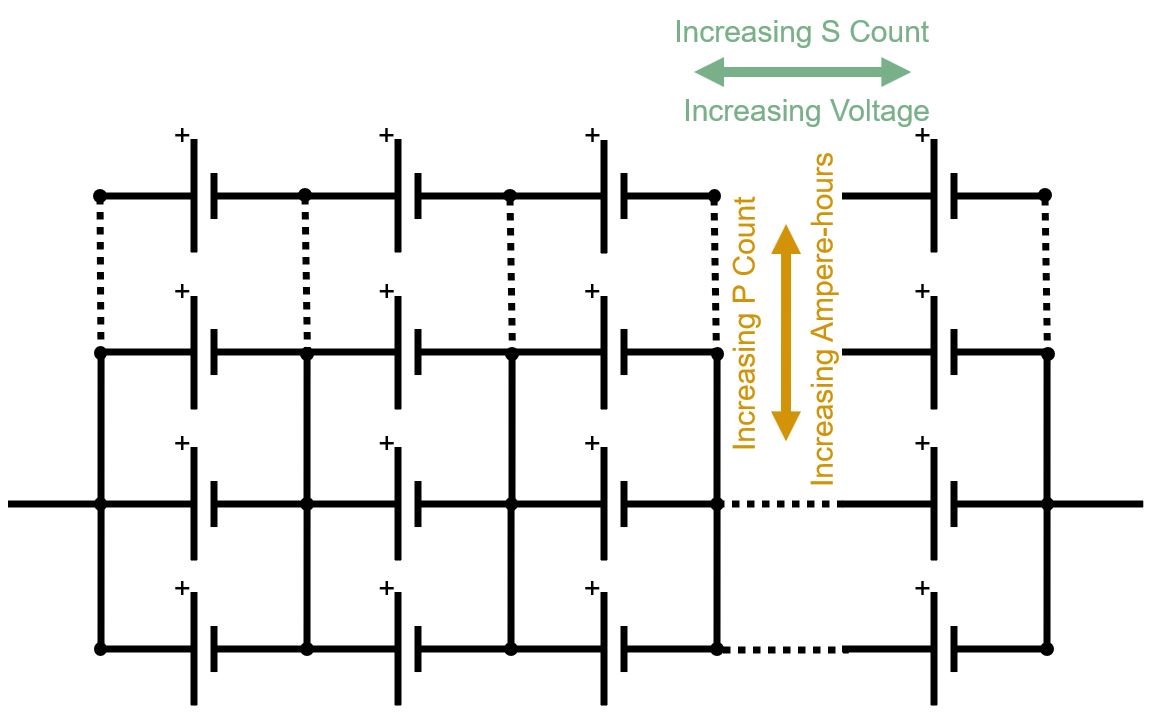

The battery in the electric vehicle will have a capacity of around ~300Ah and operate between 440V to 270V. Hence this battery will be made by connecting many cells in parallel and in series.

When you jump into your car and it is -20°C outside you will expect to drive away immediately. Go to the other extreme of driving it in a 45°C ambient and you will want full air conditioning and the ability to drive it fast down the autobahn. Running late for a meeting you could deplete the battery in under 1 hour and immediately want to fast charge it while grabbing a coffee.

If the battery in your phone starts to degrade and you have to charge it every 12 hours then you will put up with it for a few months. If the range on your electric car halves you will take it back to the garage and demand a new battery under warranty.

Of course, the vehicle battery needs to last for 10 to 15 years; however, we will want to upgrade the phone every 2 years.

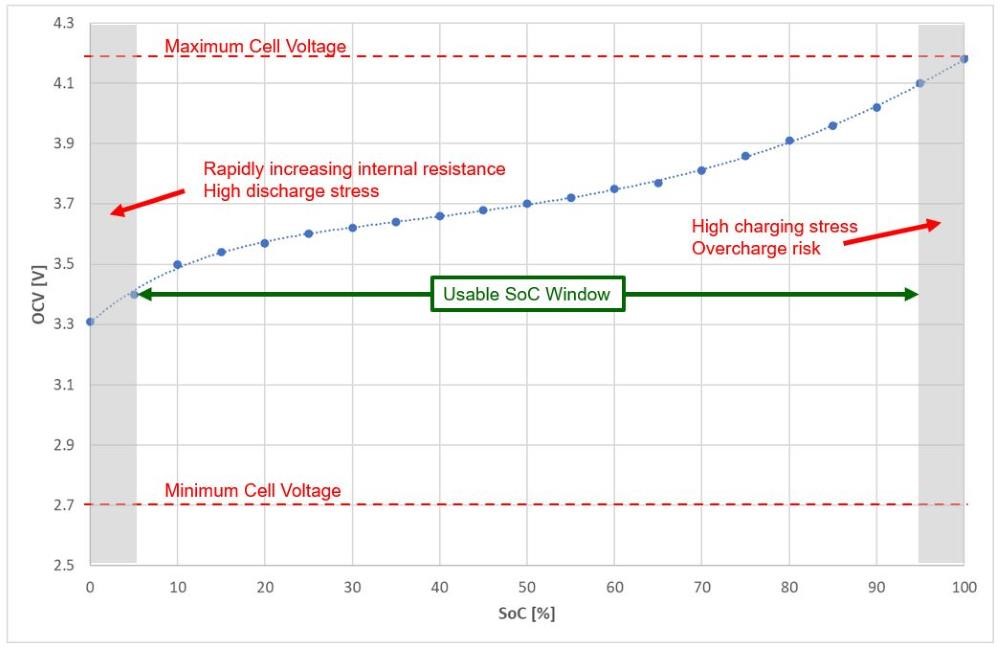

OK, there are differences in the usable SoC window of the two batteries, in the phone, they use 100% of the available capacity and in the vehicle, this is usually restricted to ~90%.

Charging to the maximum cell voltage of the battery cell puts a high stress on it, significantly reducing its life. This is one of the factors that impact battery life. One of the other factors is high temperature.

A couple of simple tips for improving the lifetime of your phone battery are:

- Remove it from charge when you see it at anything >92%

- Don’t leave it in the full sun to get even hotter

The real challenge with the multiple-cell vehicle battery is that it is only as strong as the weakest cell in the pack. If one of the cells collapses to 2.5V under load then this will limit the discharge power. This difference in cell behavior could be caused by a significant temperature gradient in the pack, this could be down to heat input from the sun or a badly designed cooling system. Designing so that all of the cells (>7000 in the Tesla Model S Plaid) behave the same thermally and hence electrically is complex when we overlay all of the operating cycles, requirements, and conditions.

So, although these two devices might share the same lithium-ion cell underpinnings the level of design, development, testing, and certification around the electric vehicle battery is significantly more complex. This makes designing an electric vehicle battery a challenge and really interesting all at the same time. Also, you get to work with chemists, and electrical, electronics, thermal, mechanical, and control engineers.

Read More: Setting up Battery Manufacturing Plant in India will be game changer for EV Industry