Table of Contents

Battery Inspection Solutions

Battery inspection solutions have become a critical aspect of the battery industry in recent years. As batteries are used in various applications such as electric vehicles, energy storage systems, and mobile devices, it is essential to ensure that they are functioning optimally and safely.

We were able to get the copy of the interview conducted by ZEISS in this regard.

From ZEISS we have our solution provider expert Mr. Manoj Sundaram, who is a seasoned professional in the Auto component and Automotive industry moving to promote solutions in the Electric vehicle domain. Nondestructive Lithium Cells, Welded Battery packs & Raw material Quality solutions are key topics for OEM’s, Cell manufacturers, Researchers, and Battery consultants. He is working with leading companies in the industry and has a deep understanding of the challenges faced by his clients. His expertise drawing from ZEISS solutions around the world has helped his clients improve the performance and safety of their batteries.

On the other hand, Mr Rahul Bollini is a well-known battery expert and consultant who is highly respected professional in the industry, with extensive experience in battery consultation. He has worked on projects related to Lithium Cell Chemistry selection, Battery integration, BMS related recommendations, lifecycle management and safety issues and has published numerous practical cases and articles on the subject. He has been a firsthand user of ZEISS Lithium Battery/Cell inspection solutions in his projects. He has expertise and is well-equipped to provide valuable insights and recommendations based on his experience.

Let’s Dive-in and Learn from their conversation.

What are the types of Lithium-ion cells? (From an Indian point of view)

The different varieties of lithium-ion cells can be divided into two categories, one based on their physical shape and the other on the raw materials that they require.

Physical Shape:

Form factor, which is another name for physical shape, may often be broken down into one of three categories: Cylindrical, Pouch, or Prismatic.

Based on Cycle Life, Capacity (in terms of the cell), and Cost, prismatic designs have more cell capacity followed by Pouch and then Cylindrical. In contrast, when it comes to flexibility in battery pack design, Cylindrical designs are the most flexible, followed by pouch designs, and then prismatic designs.

Raw Material:

LFP, NMC (which can come in five different variants), and NCA (which can come in two different forms) are the most common types of lithium-ion cells. If comparing them based on cost, service life, and reliability, LFP is superior to NMC followed by NCA.

Because it can continue to function without risk even when exposed to extreme temperatures, LFP is quickly gaining traction in the Indian market. When compared to other types of lithium-ion cells that use graphite anode, this particular type of lithium-ion cell typically has the highest cycle life and is typically the least expensive of all of the available options for lithium-ion cells. As a result, it provides excellent value for the money spent.

How is battery performance affected due to defective physical dimensional parameters form the cell considering outside parameters?

In order to have the appropriate fitment of cells in a battery pack according to the original design, the physical dimensional parameters need to be maintained in a uniform manner at all times. It is also possible for it to disrupt the thermal management architecture of the battery pack, which is particularly problematic, in the event that the battery pack has a contact-based cooling system.

Another important consideration is that the cap closure on top of the cylindrical cell must be in very good condition at all times; otherwise, there is a risk of electrolyte leakage, which can in some instances result in fire occurrences.

How about defective physical dimensional and material parameters form the inside of the cell?

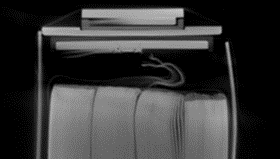

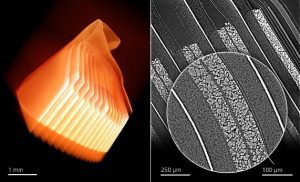

Even while every step in the production of lithium-ion cells involves very complex technology, there is still a possibility that the finished product will have flaws on the inside. This flaw typically manifests itself during the process of putting items together, such as when winding the jelly roll in a cylindrical can or performing other activities that are functionally equivalent in various form factors. As a result, several businesses have begun researching the internal workings of the cell before sending it out to its premium customers, as there is a possibility that they will lose the contract if it fails in any way. These days, this activity is becoming more common and can be found in more and more products. A lot of companies are making plans to make it a standard offering as part of their Quality process.

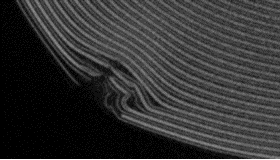

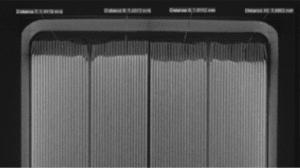

(Image courtesy: CARL ZEISS Versa 515 Xay Microscope Machine)

How these internal and external defects can be detected?

Failure analysis is something that I conduct on a regular basis, and when I need to understand the physical faults at the cell’s external level or to examine the cell internally (electrode overhang uniformity, electrode bends, tab placement), I use CT (computed tomography) scans. It provides a three-dimensional image of the cell that is exceptionally clear, allowing for in-depth analysis of the structure. It reveals the precise location of the problem, which needs to be investigated further at the nanoscale level so that a more in-depth investigation may be performed.

X-ray microscopy, often known as XRM, is a technique that I employ in order to investigate a nanoscale region of interest located within a cell. It provides a three-dimensional overview image of the region of interest so that the problem can be comprehended more completely.

SEM (scanning electron microscopy), which can analyze features with a resolution of 10 nanometers or less, is the instrument of choice for doing research on two-dimensional aspects.

Based on your interaction with us, how are ZEISS solutions supporting in this regard?

The customers I consult with have received a lot of help and support from ZEISS in their research endeavors. The measurement has turned out to be quite precise. As an example…a subject CELL under question can be studied at different resolution levels based on the requirement. A CT scan can provide insights at 30 micron resolution of the complete cell and moving to an XRM would provide resolutions of a few microns at an ROI level. Furthermore, a cell can be subject to a complete tear-down analysis in a FESEM to evaluate finer structures and study at a resolution of 0.5 Nanometers. Their FESEM has shown to be quite helpful in doing research on raw materials at the nanoscale level.

In your consultation with various customers who use ZEISS equipment, what has been their feedback, and how has been their experience for using this equipment?

The ZEISS facility in Bangalore is well-designed. After interacting with some of the businesses I am familiar with in the sector, it has come to my attention that ZEISS has been providing support to these customers and that some of these customers have even received technical support from ZEISS in locations outside of the country. This goes on to show how the feedback has been, I have never seen a company in this domain, which has a technological background on CELL/Battery inspection and offers it as a standard catalog solution.

You have now much experience with solutions from ZEISS in this space, we would like to know form you how do you feel about these recommendations from ZEISS in battery inspection.

At regular intervals, I bring Lithium-ion batteries to the ZEISS facility in Bangalore in order to have them measured. The measurement has been very exact, and I have found it to be of great use in conducting my li-ion cell failure analysis. In general, I do not have any criticisms to provide with reference to this.