Electric vehicles (EVs) are becoming the new alternatives of internal combustion engines (ICs). EVs are causing less pollution to the environment,have low operating cost, and better driving experiences. As of June 2024, more than 8.32 lakh electric vehicles have been sold in India this year alone. An Electric Vehicle which has a battery to power its driving motor is made of hundreds and thousands of cells based on vehicle size. So, a controlling unit called Battery Management System (BMS) is required for these cells to operate in safe regions.

Table of Contents

What is a Battery Management System (BMS)?

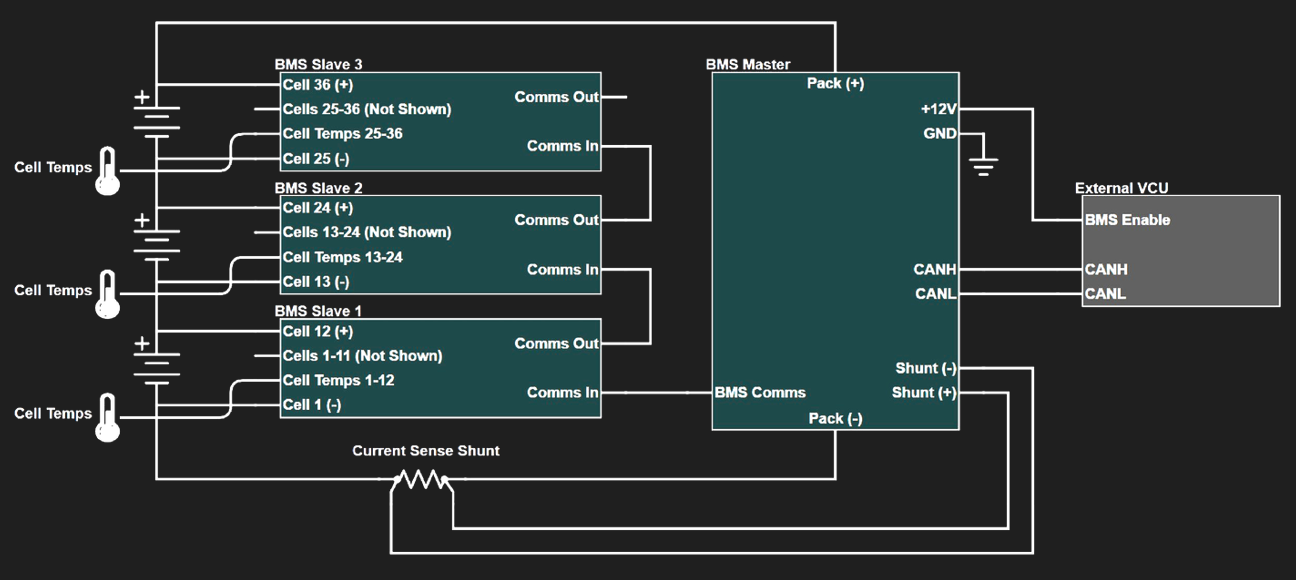

BMS is an electronic control circuit that monitors and regulates the charging and discharge of battery of an electric vehicle. BMS consists of sensors for measuring battery current, voltage, and temperature. Sensors can be installed across cells in Centralised architecture (only one BMS for entire cells) and Distributed architecture (several BMS required as it is directly installed at the cells site).

For more details: Battery Management System (BMS) for Electric Vehicle

Why is the Battery Management System (BMS) required?

BMS in the electric vehicle is the brain of the battery pack. It takes the current, voltage, and temperature temperature data from the sensors (slave boards) placed at the cell site to monitor and control the cell’s safe operating area. BMS is required for following reasons:

State Estimations

Based on the sensor data received, BMS estimates the battery states like State of Charge (SOC), State of Health (SOH), State of Power (SOP). These state estimations are required to get information on how much charge, power available in the battery to use. There are many methods to estimate these states but the Coulomb Counting with Voltage (OCV) method is most commonly used by EV manufacturers.

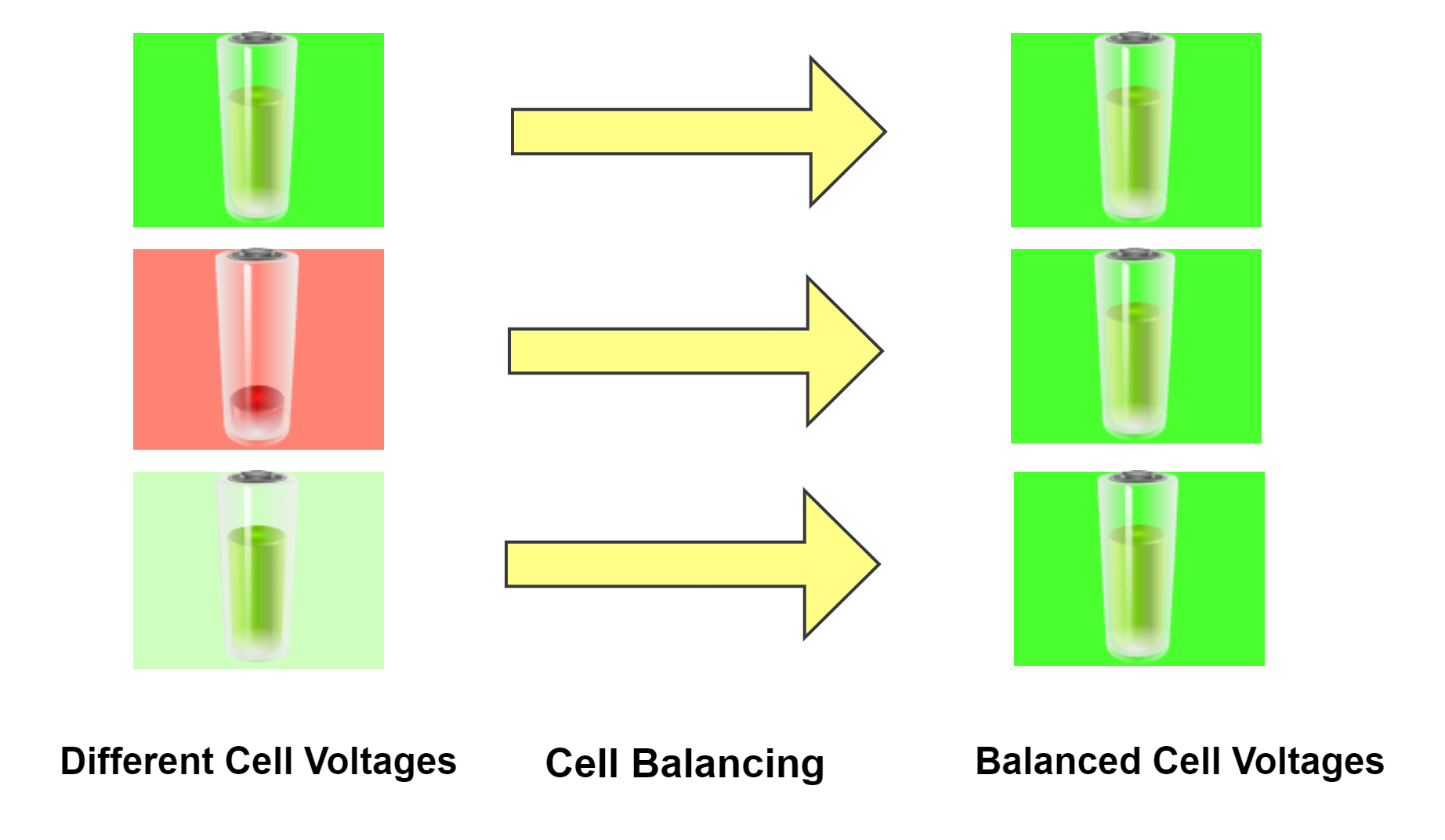

Cell Balancing

BMS performs cell balancing which means keeping all cells within certain limits of voltage and SOC. Thus Cell balancing ensures optimal use of the battery pack. It can be active cell balancing and passive cell balancing.

Active Cell Balancing is based on an inductor or capacitor where charge is transferred from high charged cells to low charge cells. Therefore, it does not dissipate electric charge as heat energy which further requires less cooling mechanism. But active cell balancing is complex and costly to implement.

Passive Cell Balancing uses a resistor to discharge the more charged cells’ energy to bring them back to other lower charged cells. And hence energy is dissipated as heat which requires a complex cooling mechanism. But this method is less complex and easy to implement.

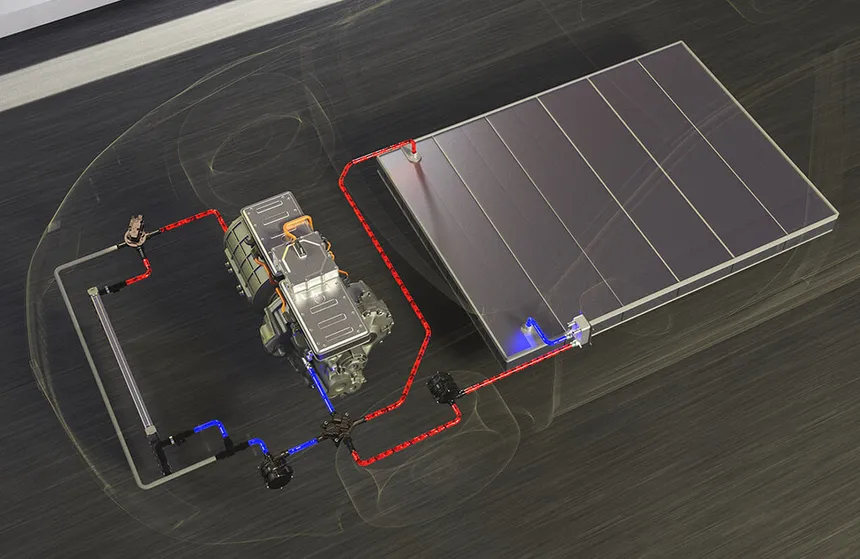

Thermal Management

Heat is generated in the battery pack of an EV because of internal resistance and chemical reactions involved inside the cell. The heat generated needs to be removed from the battery in order to safe operation of EV and to avoid thermal run and fast degradation of the battery pack.

Thermal Management can also be done in an active and passive way. Li-ion battery packs work optimally in the temperature range of 15℃ to 35℃ so BMS starts the thermal management mechanism if temperature exceeds this limit. It is generally recommended that thermal management does not exceed 20% of the weight of the whole battery pack.

Based on the cell chemistry, and battery pack complexities the following types of cooling strategies are used in Battery Thermal Management System (BTMS): Air-based, Liquid-based, Nanofluid-based, Phase change material (PCM)-based, Thermoelectric-based, and Hybrid BTMS which integrates passive and active methods to improve the passive systems’ heat transfer process and to allow their working processes to be actively controlled.

Fault Detection and Protection:

EVs batteries have a very dynamic electrical load (motor) is connected which gives a high probability of faults occurring like overcurrent, deep-discharge, short circuit,cell unbalancing and so on. So a safe operating area (SOA) is defined in the BMS at the cell as well as the battery level for voltage, current, and temperature. If any of these limits are violated then BMS turns off the contactor (switch) and thus disconnects the battery pack from the rest of electronic components. This way BMS protects the battery pack and other connected electronic components.

Communication

The BMS usually has to communicate to the Vehicle Control Unit (VCU) in order to provide status information and receive instructions and parameters. Based on the battery charge status, VCU determines the motor performance (torque) and other accessories like multimedia, cabin temperature control. Usually the Controller Area Network (CAN) interface is used to transmit messages between VCU and BMS.

Data and Event Logging

BMS also records any mishappening like overcharging, deep-discharge, balancing failure, garbage values in battery state estimation. This helps to develop more robust adaptive algorithms in the future. This also helps in providing warranty security and developing new business models.

Hardware requirement in BMS

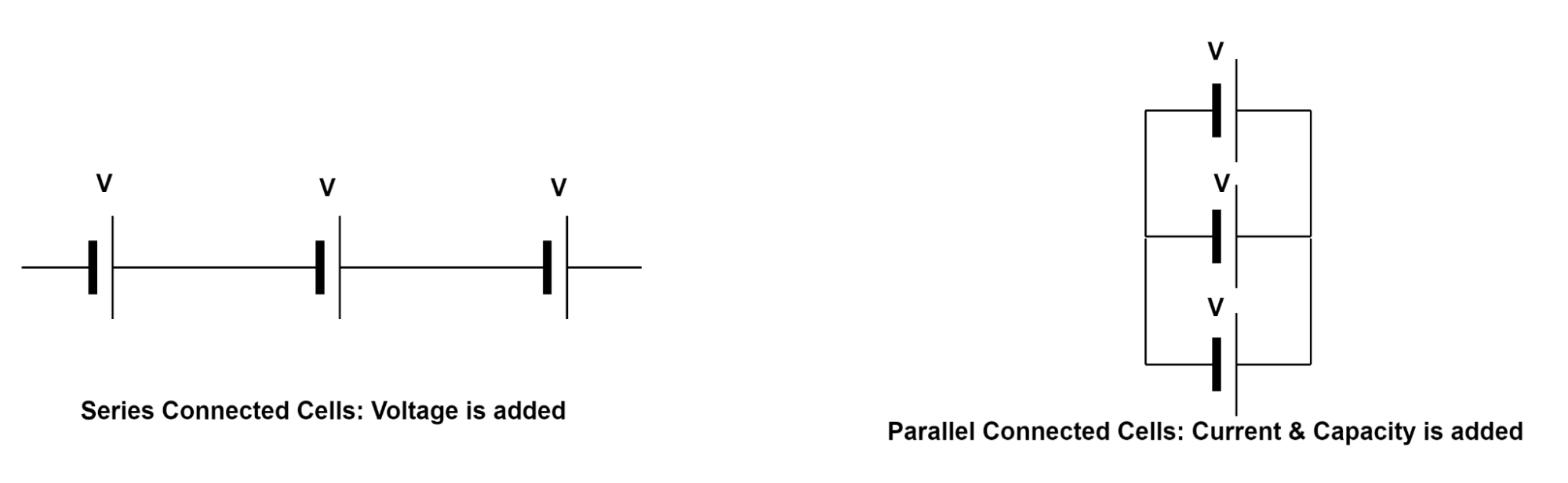

Electric vehicle battery pack of thousands of cells connected in series-parallel configuration based on the requirement of current, voltage and capacity of the battery pack. If cells are connected in series then voltage is added while if cells are connected in parallel then the current and capacity of the battery pack.

To use these all cells in safe optimal use, BMS requires the following hardware components:

Sensors

BMS uses current sensor, voltage sensor, temperature sensor (thermistor), and pressure sensor (Piezoresistive Sensor). These sensors collect the cell level data (battery pack level data in case of current sensor) and send it to the slave board (analog front end, AFE).

Current Sensor Current Sensor |  Voltage Sensor |  Temperature Sensor |

- Usually one voltage sensor is used for each cell block (cells connected in parallel, total number depends on total number of cells in parallel)

- Only one current sensor is used to measure the entire battery pack current, not used at cell level.

- Random numbers of thermistor are placed in the battery pack at different locations.

Contactor (Relay)

Contactor is a high current handling electromechanical switch that controls the flow of current between the battery pack and the external circuit (load). Usually three numbers of contactors are used in the BMS, Charge Negative, Charge Positive, and Precharge Contactor. Precharge contactor protects the electrical load from high inrush current.

- Contactor has the ability to handle high currents.

- Eliminates the problem of spark during switching.

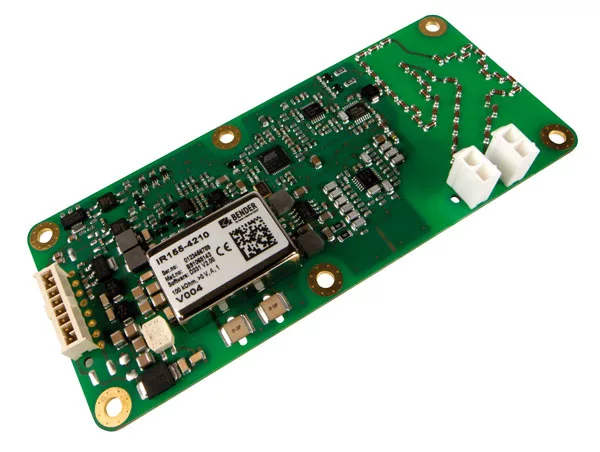

Insulation Monitoring Device (IMD)

IMD continuously monitors the insulation resistance between the battery’s high voltage terminals and ground (chassis of EV). It injects a small, safe AC current into the system and measures the resulting voltage drop. Based on this measurement, the IMD calculates the insulation resistance. If the insulation resistance falls below a predetermined safe threshold, the BMS triggers alarms and takes protective actions like Disconnecting the battery.

- Early Detection of Faults and hence enhances safety.

- Checks leakage current and hence reduces the loss of charge

Fuses

In BMS, fuses play a critical role in protecting the system from potential damage caused by overcurrent conditions. A fuse is a sacrificial device which has a thin strip of metal that melts and breaks the circuit when current exceeds safe limit.

- Fuse is simple to use and is cost-effective.

- Requires minimal maintenance.

- Fuse provides reliable Overcurrent Protection.

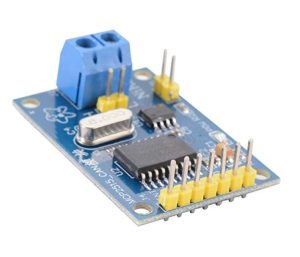

Communication Interface

CAN (Controller Area Network) and SPI (Serial Peripheral Interface) are communication protocols used within BMS. CAN is a robust, multi-master communication protocol enabling data exchange between various electronic control units (ECUs) within a system, including the BMS. It includes CAN Transceiver and CAN Bus (twisted wire).

SPI is a simpler, lower-cost communication protocol typically used for short-distance communication between the BMS microcontroller and slave boards. SPI has hardware for SPI Interface and SPI Bus (four Wires).

- CAN offers Reliable Data Transmission

- Priority-Based Messaging and is robust to noise

- SPI is cost effective and message transmission is fast.

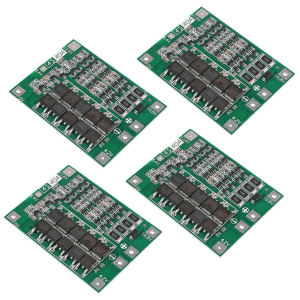

Master and Slave board

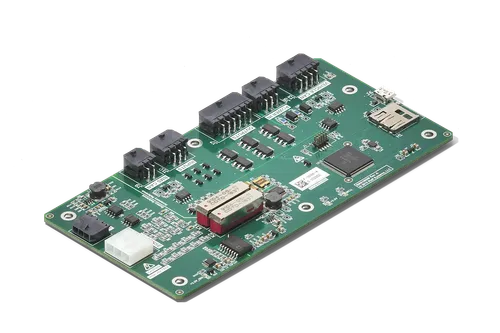

Master and Slave boards are electronic printed circuit boards (PCBs). Master board consists of Microcontroller, Memory, Power Supply Circuitry, Safety Control Circuit, Input/Output (I/O) Interfaces.

Slave boards are generally simpler PCBs compared to the master board. They primarily focus on data acquisition. It has mainly Voltage and Temperature Sensing Circuits, Communication Interface (SPI), and Cell Balancing Circuitry.

| Master board | Slave board |

|  |

- This architecture has scalability, reduce cost of BMS

- Improved Fault Tolerance, and provide redundancy to BMS

Working of Battery Management System

The slave board of BMS collects the cell data (voltage, temperature) using the sensors. Slave board has AFE which processes the received data to the master board using SPI communication channel. If voltage and temperature of cells are in safe operating area (SOA) then the contactors are turned ON and current starts flowing to the motor (load) in case of discharging or to battery in case of charging.

During charging current flows inside of the battery pack to store the charge while voltage, and temperatures are continuously monitored. If there is more deviation of voltage (40mV) between cell blocks (cell connected in parallel) then the cell balancing starts. Also if the cell gets heat while charging then coolant starts flowing to extract heat.

Also during discharging current flows out of the battery pack to power electrical load connected to it. Presently, most automobile companies use passive cell balancing so no cell balancing is done by BMS but thermal management is done if cell temperature rises above predefined limit (35℃). Also if the cell reaches minimum cut-off voltage then the contactor is turned off to prevent the cell from deep discharge. In this way, BMS monitors, controls and diagnostics the EV battery pack.

Read More: Rise Of EVs & Transition Of Automotive Manufacturing Processes