Industry 5.0 Is Not The Replacement Of Humans By Machines, But The Elevation Of Both Through Collaboration.

In 1776, the first wave of industrialisation began with the arrival of James Watt’s improved steam engine, which surpassed Thomas Newcomen’s earlier model.

Initially, these engines were used in mines and ironworks, but later, they started powering factories, ships, and locomotives, leading to the first wave of the Industrial Revolution.

A century later, in 1879, Carl Benz introduced the first stationary gasoline engine and, by 1885, built a car with an integrated engine and chassis. Patented in 1886, his invention marked a new era, but mass industrialization had to wait for Henry Ford’s breakthroughs.

Ford revolutionized automobile manufacturing by introducing mass production (introduction of the assembly line) & standardizing parts for interchangeability.

Post-WWII, Japan sparked the next transformation. At Toyota, Eiji Toyoda and Taiichi Ohno developed Lean Manufacturing—a system rooted in efficiency and continuous improvement.

Known globally as the Toyota Production System (TPS), it introduced practices like Kanban (pull systems), Andon (visual alerts), Kaizen (continuous improvement), Jidoka (intelligent automation), and waste elimination (Muda). As technology advanced, TPS principles evolved with digital tools, enabling real-time monitoring, data analysis, and process automation.

This integration of lean principles with smart technology marked the rise of a new phase of Industrialization – a new era of accelerated, data-driven production.

During the initial phases of industrialization, neither industries worried much about meeting these personalized requirements of customers nor did customers demand them as it was not a customer-oriented market (remember the famous quote from Ford in 1922, “Any customer can have a car painted any colour that he wants so long as it is black”).

In this phase, the industries were only meeting the basic needs of society. As the production numbers started increasing, it brought a dramatic shift in consumer behaviour, needs, choices & requirements & with time people started looking for customized products to meet their requirements as well as to be different from others.

The rise of Industry 5.0 is here to meet such diverse requirements of society & has forced them to change the way of their work to survive & grow. With this paradigm shift, industries are continuously evolving to remain competitive as well as darling of customers.

| Around 1940s (Industry 1.0) | Around 2020 (Industry 4.0) |

| Changes in the way of Working in the Final Assembly Line of An Automobile Plant | |

| | |

| Changes In the Way of Working in the Paint Shop of An Automobile Plant | |

| | |

| Changes In the Way of Working in the Body Shop of An Automobile Plant | |

| | |

Industrialization began around 1760 when people first learned to harness and control natural forces to reduce human effort. Early machines were developed to convert raw power into usable energy under controlled conditions.

The discovery and use of fuel sources like coal made steam-powered machinery more practical and widespread.

As production capacity grew, businesses expanded from small cottage industries to larger organizations to meet rising societal demands. This era marked a significant shift – faster, more efficient manufacturing that spurred further innovation. This phase of mastering natural power through mechanization is now known as Industry 1.0.

The Technological Revolution: The Second Industrial Revolution, also known as the “Technological Revolution,” marked a major shift in industrial development. As society gained a more advanced understanding of power and mechanical forces, electricity emerged as the primary energy source, offering greater control, ease of transmission, and operational flexibility than the steam-powered systems of the past.

This innovation allowed factories to relocate closer to consumer markets, rather than remaining near fuel sources. With increasing production demands, the manufacturing workforce grew substantially. To maintain efficiency, new management methodologies were introduced—most notably division of labour, time-motion studies, and scientific management pioneered by figures like Frederick Taylor.

These practices reduced waste and fatigue while maximizing output. The introduction of assembly lines transformed production efficiency and set a new standard for industrial practices. After World War II, Japan led the next phase of industrial excellence.

At Toyota, Eiji Toyoda and Taiichi Ohno developed what would become the Toyota Production System (TPS)—a set of lean manufacturing principles including Kanban (pull systems), Andon (visual management), Kaizen (continuous improvement), Jidoka (automation with a human touch), and Muda (waste elimination). These innovations redefined manufacturing efficiency and laid the groundwork for the transition to automated systems.

By the late 1950s and early 1960s, the growing use of semiconductors and electronics began transforming these manual systems into automated processes—paving the way for the next industrial era.

Industry 3.0, or the Digital Revolution, was driven by groundbreaking advancements in electronics and computing.

It began with the invention of the transistor in 1947 by John Bardeen, Walter Brattain, and William Shockley at Bell Labs.

This was followed by Jack Kilby’s creation of the first integrated circuit (IC) in 1958, which revolutionized electronics and opened the door to modern automation. By the 1970s, the manufacturing sector began integrating electronics and information technology, enabling greater automation of tasks that previously required manual intervention. Early computers, though limited in power, laid the foundation for this transformation.

The use of transistors and ICs allowed for programmable machines, control systems, and faster data processing. In 1970, Gordon Moore introduced Moore’s Law, predicting that the number of transistors on a chip would double every two years while costs halved—driving exponential growth in computing power.

This evolution spurred rapid development in both hardware and software, leading to the widespread deployment of programmable logic controllers (PLCs) and computer-aided manufacturing (CAM) across industries.

During this period, globalization surged. Manufacturers began relocating operations to low-cost regions, increasing the need for formalized supply chain management and real-time data exchange. By the early 2000s, the rise of the internet and cloud technologies brought hyper-connectivity to production systems, setting the stage for smart manufacturing.

Despite high levels of automation, human oversight remained essential—especially in areas requiring judgment and adaptability. Industry 3.0 was a pivotal transformation, but it also signalled that an even more intelligent and integrated era was just around the corner.

The term Fourth Industrial Revolution or Industry 4.0 was introduced by Klaus Schwab, Executive Chairman of the World Economic Forum, in a 2015 article.

In essence, it marked the next phase of evolution beyond Industry 3.0 – focused on optimizing and expanding computerization through interconnected systems and intelligent automation. As manufacturing processes became increasingly automated, systems began to connect not just through wired networks but also via the cloud, communicating over the Internet to make autonomous decisions.

This transition was fueled by a convergence of cyber-physical systems, the Internet of Things (IoT), and the Internet of Systems—laying the foundation for what we now call the smart factory. In Industry 4.0, machines are not only automated but intelligent, continuously improving as they access more data and computational power.

These smart-systems exchange information, trigger actions, and coordinate operations with minimal or no human intervention.

As a result, factories have become more efficient, productive, and sustainable. Key enabling technologies of Industry 4.0 include additive manufacturing, robotics, artificial intelligence, cognitive computing, advanced materials, augmented reality, and cloud computing. Earlier concepts like Manufacturing Execution Systems (MES), Shop Floor Control, and Product Lifecycle Management, once ahead of their time, have now become fully viable through the Industrial Internet of Things (IIoT).

| Core Components of Industry 4.0 | Key Outcomes of Industry 4.0 | |

| Cyber-Physical Systems (CPS): Mechanical Systems Controlled by Computer-Based Algorithms. Internet Of Things (IoT): Networks of Connected Machines, Vehicles, And Devices with Sensing and Monitoring Capabilities. Cloud Computing: Offsite Data Storage, Backup, And Processing Capabilities. Cognitive Computing: AI-Driven Platforms That Mimic Human Thinking to Analyze Data and Support Decision-Making. | Enhanced Connectivity: Real-Time Digital Communication and Integration Across Processes. Process Optimization: Greater Efficiency, Reduced Errors, And Minimal Waste Through Automation and Data-Driven Decision-Making. Seamless Coordination: Fully Digitalized Supply Chains—From Sourcing to After-Sales Service. New Business Models: Transition To “Servitization”. |

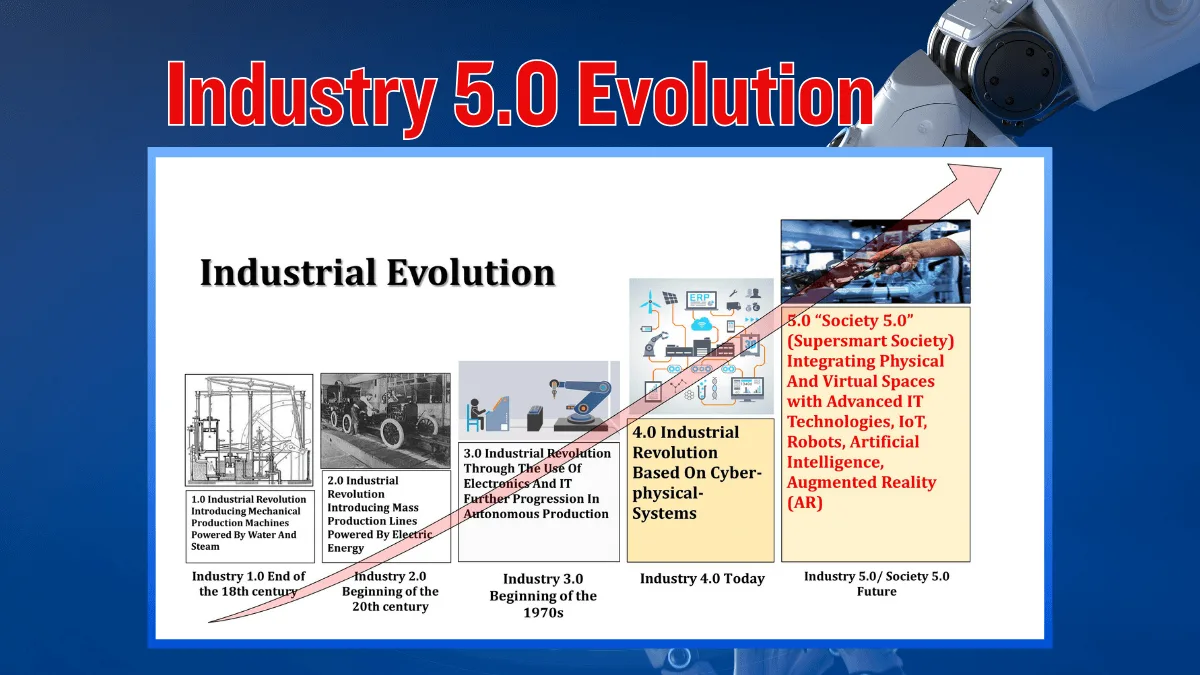

Less than a decade after the rise of Industry 4.0, the manufacturing world is already looking ahead to the next wave, Industry 5.0. While Industry 4.0 focused on smart factories powered by IoT, cognitive computing, and cloud connectivity, Industry 5.0 shifted the spotlight back to humans—emphasizing collaboration between people and intelligent machines. Though it’s hard to pinpoint an exact starting date, 2020 marked a turning point.

The COVID-19 pandemic highlighted the need for flexible, resilient systems that balance automation with human judgment. While minimizing human presence was necessary for safety, complete reliance on machines proved insufficient – underscoring the need for a more collaborative model. Industry 5.0 centres on humans and machines working together.

It’s not just about automation; it’s about cobots (collaborative robots) enhancing human capabilities through technologies like IoT, big data, and AI.

These smart machines assist, not replace – handling repetitive, dangerous, or strenuous tasks while humans provide creativity, decision-making, and adaptability.

In essence, Industry 5.0 is a natural progression of Industry 4.0, aiming to merge human intuition with machine precision. Ironically, as many companies are just now adopting Industry 4.0 principles, others are already stepping into the future with Industry 5.0 – where technology empowers humans rather than replaces them.

| Industry 1.0 | Industry 2.0 | Industry 3.0 | Industry 4.0 | Industry 5.0 |

| Mechanization, Water Power, Steam Power | Mass Production, Assembly Line, Electricity | Computers & Automation | Digitalization, Cyber-Physical Systems | Mass Customization & Cyber-Physical Cognitive System |

The first is human-robot collaboration, where humans and machines work side by side. In this model, robots handle repetitive or physically demanding tasks, while humans focus on creativity, problem-solving, and strategic thinking.

The goal is to combine the precision of machines with the ingenuity of people to enhance productivity and innovation. While second vision is the rise of the bioeconomy – the smart, sustainable use of biological resources for industrial applications. This approach aims to balance ecology, industry, and the economy.

According to the European Commission, the bioeconomy involves producing renewable biological resources and converting them, along with waste streams, into value-added products such as food, bio-based materials, and bioenergy. It spans sectors like agriculture, forestry, fisheries, food production, and parts of the chemical, biotech, and energy industries. The bioeconomy thrives on interdisciplinary innovation, drawing from life sciences, agronomy, ecology, ICT, biotechnology, nanotechnology, and local knowledge.

Beyond these, emerging themes such as space industries, space life, and space mining are also gaining attention as potential components of the next industrial revolution. With growing interest in extraterrestrial resource extraction, scientists are urging caution, warning that space mining could spark a modern-day “gold rush” with significant ethical and environmental implications.

| Head | Industry 4.0 | Industry 5.0 (Ver 1) | Industry 5.0 (Ver 2) |

| Motto | Smart Manufacturing | Human-Robot Co-working | Bio-Economy |

| Motivation | Mass Production | Smart Society | Sustainability |

| Power Source | Electrical Power, Fossil-Based Fuels, Renewable Power Sources | Electrical Power, Renewable Power Sources | Electrical Power, Renewable Power Sources |

| Involved Technologies | Internet Of Things (IoT), Cloud Computing, Big Data, Robotics and Artificial, Intelligence (AI) | Human-Robot Collaboration, Renewable Resources | Sustainable Agricultural, Production, Bionics, Renewable Resources |

| Involved Research Areas | Organizational Research, Process Improvement and Innovation, Business Administration | Smart Environments, Organizational Research, Process Improvement and Innovation, Business Administration | Agriculture, Biology, Waste Prevention, Process Improvement and Innovation, Business Administration, Economy |

However, it’s a matter of time before will tell us, finally which version takes over, yet few factors are pushing the industry towards its new version which is sometimes also called Society 5.0 instead of Industry 5.0.

The current generation’s product choices are largely driven by their beliefs, personal preferences, and individual identities rather than popularity alone. This generation is also looking for a personalized service when they go out and search for a product or service & they are willing to pay a premium for that extra service being provided to them.

Statistics tell us that 58% of new-age consumers with a monthly income of more than $6,000 are willing to pay more for personalized offers while 70% of them will pay a premium for goods from brands that embrace causes they identify with.

Similarly, 62% of customers are ready to pay more to customize their electronic devices, such as phones and tablets. The modern customer is already spoiled by highly personalized digital services thanks to Amazon, Netflix and the like. Now they want to bring that newly developed habit to the physical realm.

| Industry | Examples of Mass Customization | Examples of ultra-personalization |

| Apparel | The ability to choose custom design elements (colors, materials etc.). | Ability to produce on as per customer’s unique body shape based on personal data/ body scans. |

| Food | Assemble your own sandwich or salad; customized CPG products such as beverages, pre-made meals, etc. | Ultra-personalized meal plans or supplements created using a customer’s DNA or health data |

| Automotive | Customization of vehicle aesthetics and configurations | Advanced personalization to meet a customer’s ergonomic preferences, and design tastes such as custom-built engines, steering, and seats. ADAS, etc. |

There is a study that shows that by 2030, most American consumers expect personalized products and services to be commonplace and are willing to pay a premium for them.

Factor B: Public Concerns Regarding Sustainability and Overproduction – Providing customers with the right products at the right time can reduce dead stock, production waste, and logistics costs associated with returns and recalls.

Factor C: The Rise of On-Demand Services and Sharing Business Models – Bringing intelligent and connected products to the market and launching serviced offerings can help manufacturers maintain a connection with every customer long after the initial sale.

Factor D: Availability Of Technology – There are various methods, tools, and technologies available to meet this requirement. With rapid advancements in technology, we’ve seen significant progress in machine learning, deep learning, and artificial intelligence. At the same time, industrial robotics has reached new levels of precision and reliability. The latest generation of machine vision–powered systems can now inspect products and detect potential defects with greater accuracy than human operators. Some pioneers in the industry have even taken it a step further, integrating robots to work side by side with humans on the manufacturing floor.

While the ultimate vision of Industry 4.0 was near-total automation, Industry 5.0 places a stronger emphasis on the interplay between humans and machines, there are several factors are contributing to the rise of ultra-personalized products and services:

The main goal of Industry 5.0 is to create a new vector of collaboration between humans and technology (robots, cobots, IoT devices, and other cognitive systems) at production facilities and beyond.

Transitioning to a more agile supply chain and manufacturing process is the first integral step toward mass personalization.

However, to remain personal, these processes will also need to include a human touch i.e. input from customers and the production team that too on a real-time basis. And at the end of the day, the viability of mass personalization strongly depends on its cost-effectiveness.

| Current Scenario | Evolvement |

| |

Most customer data needed for hyper-personalization is often locked in silos or can’t be efficiently routed to a centralized system for real-time analysis.

The key to solving this challenge is building a unified data management platform – one that can gather and process customer insights across touchpoints, seamlessly distribute them throughout the supply chain, and make them instantly accessible to various departments.

Mass customization adds complexity to the manufacturing process, making it difficult to assess the performance of modified products without physical prototypes.

However, building prototypes for each variation can significantly increase costs. A promising alternative is the use of digital twins—virtual models of complex processes, products, or services. With today’s advancements in machine learning, these digital replicas can closely mirror real-world counterparts, enabling detailed simulations that enhance design, predict failures, and optimize performance.

Mass customization adds significant complexity to manufacturing, making it challenging to predict the performance of tailored products without prototypes.

However, producing physical prototypes for each custom variation can drive up costs. To address this, more advanced AI systems – powered by deep learning and reinforcement learning – are needed to enable autonomous manufacturing of customized parts.

These systems must be capable of making optimal decisions even when faced with incomplete or missing customer inputs. Additionally, AI agents, managing production will require robust monitoring tools, especially for inventory control, supply and demand balancing, and predictive maintenance.

In most cases, industrial automation doesn’t eliminate the need for human workers on the manufacturing floor. Instead, humans and autonomous systems are required to collaborate safely in shared workspaces.

Advancements in computer vision and deep learning have enabled modern industrial systems to recognize and respond to the presence of human operators in real-time.

Today’s collaborative robots, or cobots, come equipped with enhanced cognitive capabilities, allowing them to assist with tasks like palletizing, assembling small components, packaging, polishing, and inspecting. However, most current-generation cobots still rely heavily on basic sensor data – such as distance, speed, and proximity – which limits their learning and adaptability in dynamic environments.

Most off-the-shelf enterprise resource planning (ERP) systems are not equipped to track individually customized parts – such as those produced through 3D printing. These systems often treat custom items as a single SKU, which can lead to errors if parts aren’t labelled manually, resulting in customers receiving incorrect products.

To ensure quality and traceability, it’s critical to maintain comprehensive digital records at every stage of the design and manufacturing process. This not only helps reduce waste and improve quality control but also unlocks greater value from additive manufacturing. To effectively integrate additive manufacturing into their operations, companies must rethink their data architecture and establish a robust pipeline for real-time, actionable insights.

Automation isn’t a threat to human jobs – it’s an opportunity to shift away from the 3D tasks (dirty, dangerous, and difficult) and move toward 3C work (Collaborative, Creative, and Custodial work roles). Even with rapid advancements in AI and robotics, humans will continue to hold a vital place in the workforce.

One of the key areas is ideation. Humans have an innate ability to generate novel ideas, connect seemingly unrelated concepts, and develop inventive solutions to complex problems. While self-learning algorithms can produce new ideas, they lack the intuition and real-world understanding needed to evaluate their practicality and impact.

Upgrading tools and manufacturing processes is just one part of the AI-driven industrial revolution. Investing in talent to support those new initiatives is far more crucial for long-term success. For 36% of manufacturers, the technical skills gap is a major stumbling block to realizing more value from their smart factory investments.

In addition, 57% of industrial leaders say they lack AI talent – the enablers for all the autonomous and intelligent solutions that are to take over the 3D chores. Sourcing the right talent is just one piece of the puzzle, though. Upskilling and training existing employees are far more crucial. Smart tech isn’t taking over human jobs per se.

But it is radically changing the ideal employee skill set.

We can easily summarize that what we as a society are looking forward for a

While in Industry 4.0 focus was on Mass production with high efficiency and low waste, the focus in Industry 5.0 shifted to Mass personalization with high accuracy and at low cost allowing tighter collaboration between cognitive systems, robots, and humans can help businesses harmonize manufacturing processes and become more agile to accommodate market changes and customization requests.

In This Regard, Probably, The More Exact Term Instead of Industry 5.0 Is “Society 5.0” (Supersmart Society) an alternative That Was Offered In 2016 By Japan’s Most Important Business Federation, Keidanren and Being Strongly Promoted by the Council for Science, Technology and Innovation; Cabinet Office, Government of Japan.

Unlike The Concept of Industry 4.0, Society 5.0 Is Not Restricted Only to A Manufacturing Sector, But It Solves Social Problems with The Help of Integration of Physical and Virtual Spaces.

Society 5.0 Is a Society Where Advanced IT Technologies, IoT, Robots, Artificial Intelligence, Augmented Reality (AR) & Cobots Are Actively Used in People Common Life, In the Industry, Health Care and Other Spheres of Activity Not for Progress, But for The Benefit and Convenience of Each Person.

The Government of Japan has rightly said that in “Realizing Industry 5.0 as we move into Society 5.0 all people’s lives will be more comfortable and sustainable as people are provided with only the right & exact products and services in the amounts and at the time needed.”

This post was last modified on June 15, 2025 1:36 am

In a major stride toward sustainable mobility, the Himachal Pradesh Police have incorporated six custom-modified Tata Curvv electric vehicles into…

In India, the automotive and transport industry is undergoing significant changes. This transformation isn't just about improving roads and infrastructure;…

Montra Electric, the clean mobility brand from the prestigious Murugappa Group, has launched the All-New Super Auto, a next-generation electric…

Union Minister Nitin Gadkari (Minister of Road Transport and Highways of India) has once again made a bold statement that’s got…

India’s electric four-wheeler (E4W) market slowed in September 2025, following a record-breaking August, with 15,038 units sold, representing an 18%…

India’s EV market hit 1,04,056 electric two-wheeler sales in September 2025. TVS, Bajaj, and Ather led the chart, while Ola…

This website uses cookies.