Over the last 15 years, the average price of lithium-ion battery packs for light-duty electric vehicles (EVs) has dramatically reduced by 90%, according to estimates by the U.S. Department of Energy (DOE).

In 2023, the DOE estimated that the average price of these battery packs was $139 per kilowatt-hour (kWh) on a usable-energy basis when produced at scale (100,000 units or more per year).

Although this price is still above the $100/kWh mark that many analysts believe will bring EVs to cost parity with gasoline-powered vehicles, it significantly drops from the $1,415/kWh average price (adjusted to 2023 dollars) observed in 2008.

The DOE attributes this steep decline to advancements in battery technologies, chemistries, and manufacturing, along with a substantial increase in production volumes since the launch of the modern EV era.

The increase in production volume has been one of the key factors driving down the cost of EV battery packs.

When the Tesla Roadster was introduced in 2008, marking the beginning of the modern EV era, production volumes were relatively low, which limited the economies of scale that automakers could achieve.

However, as the demand for EVs grew, production volumes increased, allowing manufacturers to spread out the fixed production costs over a larger number of units, thereby reducing the average cost per battery pack.

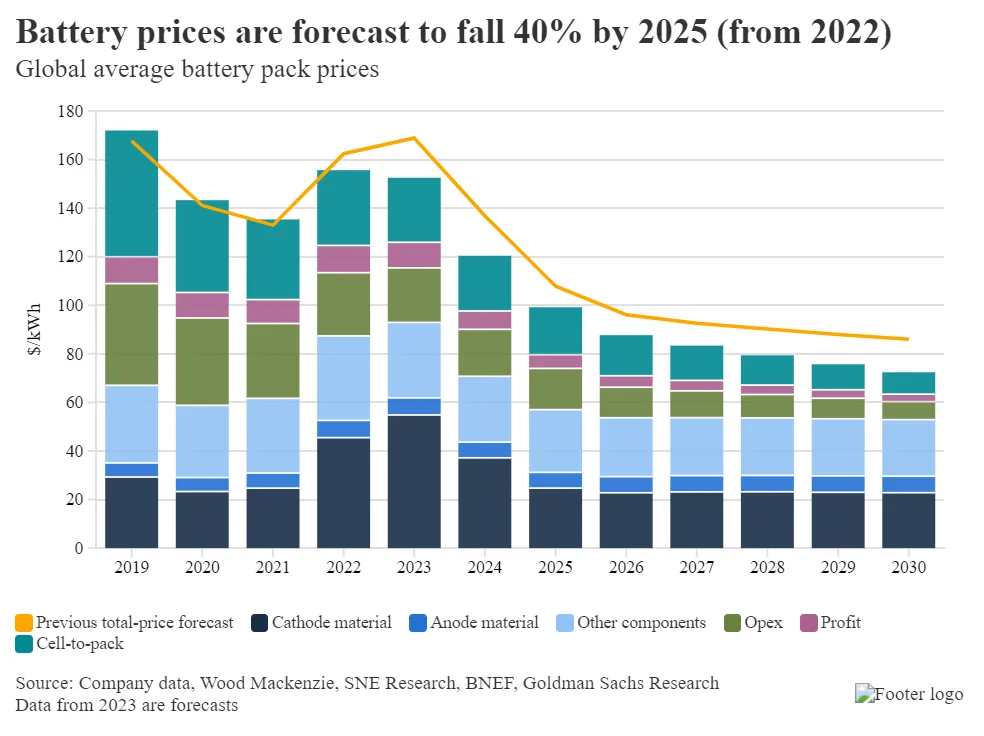

Despite the overall downward trend in battery prices, there have been some fluctuations in recent years.

For example, battery prices dropped by 13% in 2019 but saw an increase in 2022 due to disruptions caused by the coronavirus pandemic and related supply chain issues.

However, prices resumed their decline in 2023, with a reported 14% drop, according to Bloomberg New Energy Finance.

On the technology side, Tesla has been focusing on large-format 4680 cells as a potential solution for reducing EV costs, but this initiative has not yet achieved the desired cost savings.

In fact, during Tesla’s annual shareholder meeting in June 2023, CEO Elon Musk acknowledged that the company’s own 4680 cells were still more expensive than those purchased from suppliers.

Looking ahead, battery costs are expected to continue their downward trajectory.

Earlier this year, Goldman Sachs released an analysis predicting that battery costs could decrease by an additional 40% between 2023 and 2025.

If this prediction holds, it could enable EVs to achieve cost parity with internal combustion vehicles as early as next year in some markets.

This would be a significant milestone for the EV industry, potentially accelerating the adoption of electric vehicles on a global scale.

This post was last modified on August 12, 2024 7:12 am

In a major stride toward sustainable mobility, the Himachal Pradesh Police have incorporated six custom-modified Tata Curvv electric vehicles into…

In India, the automotive and transport industry is undergoing significant changes. This transformation isn't just about improving roads and infrastructure;…

Montra Electric, the clean mobility brand from the prestigious Murugappa Group, has launched the All-New Super Auto, a next-generation electric…

Union Minister Nitin Gadkari (Minister of Road Transport and Highways of India) has once again made a bold statement that’s got…

India’s electric four-wheeler (E4W) market slowed in September 2025, following a record-breaking August, with 15,038 units sold, representing an 18%…

India’s EV market hit 1,04,056 electric two-wheeler sales in September 2025. TVS, Bajaj, and Ather led the chart, while Ola…

This website uses cookies.