India is progressing rapidly towards a cleaner energy future. Whether it’s electric vehicles (EVs), rooftop solar installations, or industrial power backups, lithium-ion batteries have become central to this transition.

In 2023, India recorded over 1.53 million EV sales, nearly double the previous year’s figures. According to a report by NITI Aayog and RMI India, the country’s battery demand is expected to grow to between 106 GWh and 260 GWh by 2030, driven by EVs and renewable energy storage requirements.

However, as adoption increases, so do the safety risks — particularly the risk of battery fires caused by overheating or failure.

Lithium-ion batteries are energy-dense and efficient, but also sensitive to manufacturing flaws, mechanical damage, or thermal stress.

One of the most dangerous failure modes is thermal runaway, where internal temperatures rise rapidly and uncontrollably, leading to fires or explosions.

South Korea reported over 23 fire incidents at battery energy storage sites.

In the United States, a 2019 battery explosion in Arizona injured multiple firefighters.

A large battery fire in Australia in 2021 required several days to bring under control.

Most recently, a major fire at sea underscored the global relevance of battery safety.

On June 3, 2025, the cargo vessel Morning Midas caught fire while transporting around 3,000 vehicles, including 800 electric vehicles, across the Pacific Ocean. The fire could not be contained, and the ship eventually sank 415 miles off the coast of Alaska.

While the exact cause is under investigation, experts believe the presence of EV batteries significantly contributed to the intensity and uncontrollability of the fire.

India has also witnessed several serious incidents:

In 2022, battery fires involving brands like Ola, Okinawa, and Pure EV raised national concern.

In Telangana, a battery explosion led to the deaths of eight people after a fire spread inside a residential building.

In 2023, a fire at a BESS installation in Maharashtra caused substantial power disruption and infrastructure damage.

These cases highlight the urgent need for stronger battery safety standards and proactive testing at all levels.

In response to rising safety concerns, the Government of India has introduced several important measures:

The Ministry of Road Transport and Highways (MoRTH) now mandates advanced safety testing protocols for EV batteries, including robust Battery Management Systems (BMS) and abuse resistance evaluations.

The Bureau of Indian Standards (BIS) has released new fire safety and structural integrity guidelines for battery packs and enclosures.

The Ministry of New and Renewable Energy (MNRE) has implemented multi-stage safety testing for large-scale BESS installations as part of the National Energy Storage Mission.

These measures aim to build long-term trust in India’s clean energy infrastructure.

Battery Energy Storage Systems (BESS) store surplus energy from solar, wind, and the grid. However, because they involve high-voltage lithium-ion batteries in large volumes, they must undergo rigorous fire safety testing to prevent catastrophic failures.

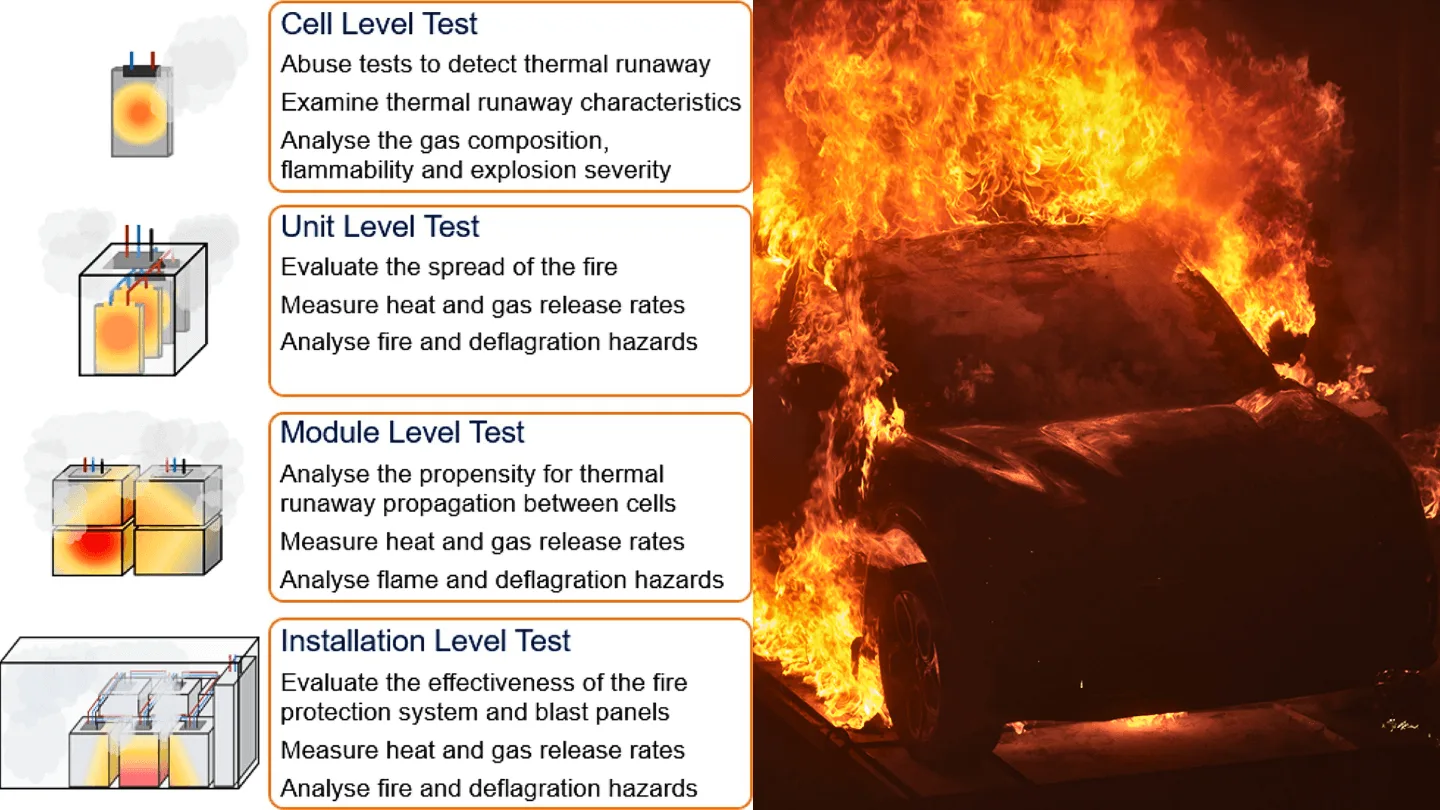

The following four-stage testing framework addresses thermal safety from the smallest component to full-scale installations.

This stage simulates battery cell failure under extreme conditions. It helps detect early signs of thermal runaway and explosion risks.

Key evaluation parameters:

Gas release and flammability

Initial heat detection

Cell explosion thresholds

Even a few milliseconds of delayed detection can escalate into a much larger incident. Early intervention is critical.

This level examines how a single failing cell can affect others within the same battery unit. It focuses on:

Fire and heat propagation

Gas dispersion behaviour

Ventilation and containment effectiveness

Effective unit-level design can prevent chain reactions from spreading across the entire battery system.

Here, multiple cells and units are tested together to simulate real operational stress. The goal is to understand:

Flame propagation dynamics

Behaviour of passive and active cooling systems

Overall system stability under failure

This is a critical layer in preventing widespread system failures due to localised thermal events.

At this final level, the complete BESS setup is tested under real-world scenarios. This includes:

Fire suppression system validation

Structural integrity of enclosures and blast panels

Emergency response effectiveness

These tests determine whether a BESS installation is truly safe for use in homes, commercial buildings, charging stations, or grid-scale facilities.

As battery systems are deployed across urban and rural India, the consequences of inadequate safety measures can be devastating to lives, infrastructure, and public confidence in clean energy.

This four-level testing framework is not just a regulatory requirement. It is a critical safety protocol for protecting people, property, and the reliability of our national energy systems.

India’s clean energy goals are ambitious, and the progress so far has been commendable.

However, as we move forward with EVs, solar energy, and battery-backed systems, safety must evolve in tandem with innovation.

By embedding multi-stage fire testing into the battery development cycle, we can ensure that our energy systems are not only sustainable but also secure.

Note: This framework and detailed insights were originally shared by Neeraj Kumar Singal on his LinkedIn profile.

Neeraj Kumar Singal is the Founder and CEO of Semco Group, a leading provider of lithium-ion cell manufacturing, battery testing, and BESS integration services. With over two decades of experience in advanced energy systems, he actively contributes to India’s energy transformation journey, focusing strongly on quality, compliance, and public safety.

This post was last modified on August 7, 2025 11:44 am

Montra Electric, the clean mobility brand from the prestigious Murugappa Group, has launched the All-New Super Auto, a next-generation electric…

Union Minister Nitin Gadkari (Minister of Road Transport and Highways of India) has once again made a bold statement that’s got…

India’s electric four-wheeler (E4W) market slowed in September 2025, following a record-breaking August, with 15,038 units sold, representing an 18%…

India’s EV market hit 1,04,056 electric two-wheeler sales in September 2025. TVS, Bajaj, and Ather led the chart, while Ola…

India's electric two-wheeler market is growing at a record pace. In July 2025, over 1.2 lakh electric two-wheelers were sold,…

The future of mobility in India has taken a major leap forward. Omega Seiki Mobility (OSM), led by Founder Uday…

This website uses cookies.