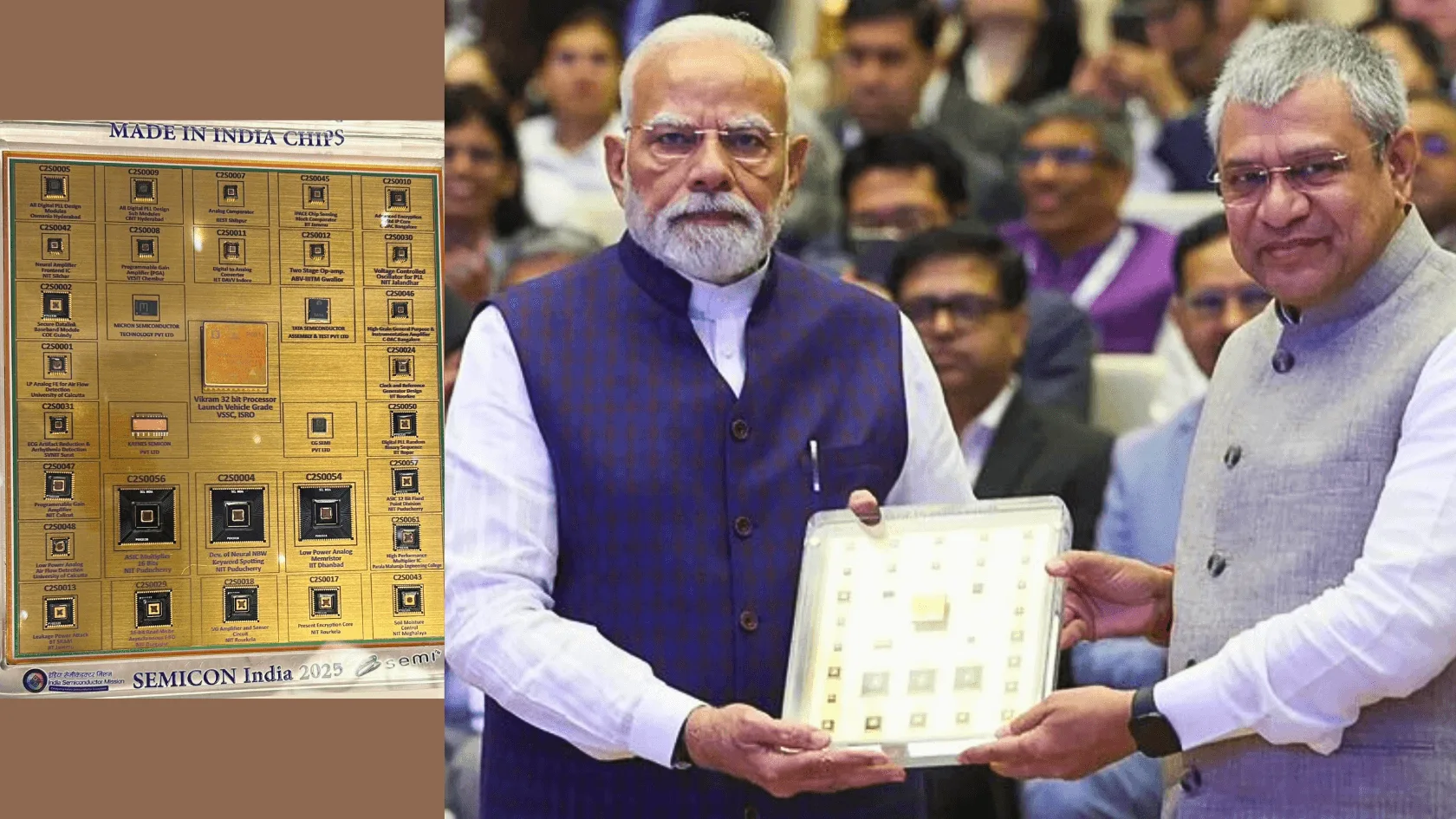

At Semicon India 2025, a defining moment unfolded when Prime Minister Narendra Modi was presented with the Vikram-32 processor—India’s first fully indigenous launch vehicle-grade microchip, developed by ISRO.

On the surface, this achievement marks a leap in space technology. But beneath the headlines lies a story with profound implications for another sector racing ahead—India’s electric vehicle (EV) industry.

Union IT Minister Ashwini Vaishnaw formally handed over the Vikram-32 to the Prime Minister, calling it a “historic milestone.” Industry leaders echoed the sentiment, celebrating it as a turning point in Atmanirbhar Bharat’s semiconductor journey, with chips now being hailed as the “digital diamonds of the 21st century.”

The showcase didn’t stop at Vikram-32. More than two dozen Made-in-India chips were unveiled—from analog comparators and op-amps to encryption modules and neural network ICs—designed by IITs, NITs, research centers, and startups across the country.

Analog Comparators & Two-Stage Op-Amps (IIEST, ABV-IIITM, NITs): Essential for motor drive circuits and battery monitoring.

Low-Power Analog Memristor (NIT Dhanbad): Promising for AI-driven features like predictive maintenance and smart energy use.

Secure Datalink & Encryption Modules (COE Guindy, NIT Rourkela): Critical for cybersecurity, especially in over-the-air updates and EV charging payments.

Neural Network ICs (NIT Silchar, Puducherry): Foundational for driver-assist systems (ADAS) and real-time route optimization.

Voltage-Controlled Oscillators & Multipliers (NIT Jalandhar, Puducherry): Core elements in EV inverters and charging stations.

High-Performance Multiplier (Parala Maharaja Engg. College): Boosts processing speeds for motor control algorithms.

PLI Scheme: ₹76,000 crore for semiconductor manufacturing.

Design-Linked Incentives (DLI): Supporting 23+ chip design projects nationwide.

EV30@2030 Mission: Aiming for 30% EV penetration by 2030.

Strategic Synergy: Chip independence strengthens the entire EV ecosystem.

While the Vikram-32 itself is designed for space missions, its real significance lies in proving India’s capability to design high-reliability processors.

The same ecosystem, experts argue, can pivot to automotive-grade semiconductors—a market projected to cross $100 billion globally by 2030. Read about New Electric Cars Launching in September 2025 – Maruti, Hyundai, Volvo & More

Electric vehicles are, at their core, computers on wheels. Every function—battery management, motor control, power electronics, safety, infotainment—runs on semiconductors.

Globally, EV rollouts have often stalled due to chip shortages, underscoring the importance of local semiconductor capacity. By developing its own chips, India can cut EV costs, secure supply chains, and accelerate adoption.

Semicon India 2025 was more than a showcase of technological progress—it was a statement of intent.

By building chips at home, India is laying the foundation for its EV revolution, ensuring everything from smarter batteries to AI-driven driving intelligence is powered by indigenous silicon.

As PM Modi aptly put it, “The world’s biggest change will be powered by India’s smallest chip.” For electric vehicles, those words may prove prophetic.

This post was last modified on September 3, 2025 11:08 am

Montra Electric, the clean mobility brand of the Murugappa Group, has unveiled its state-of-the-art electric heavy commercial vehicle (eHCV) manufacturing…

The festive season in India is always considered the right time for new purchases — whether it’s gold, gadgets, or…

Ultraviolette Automotive, the Bengaluru-based electric mobility startup behind the F77, has unveiled its most ambitious motorcycle yet: the X47 Crossover.…

The festive season is always a time of high demand, and Montra Electric is making sure no customer has to…

Mercedes-Benz has officially unveiled the GLC Electric at the IAA Mobility show, a move that electrifies its best-selling SUV while…

Noise, in collaboration with TVS Motor Company, has launched India’s first smartwatch that directly integrates with an electric scooter. The…

This website uses cookies.