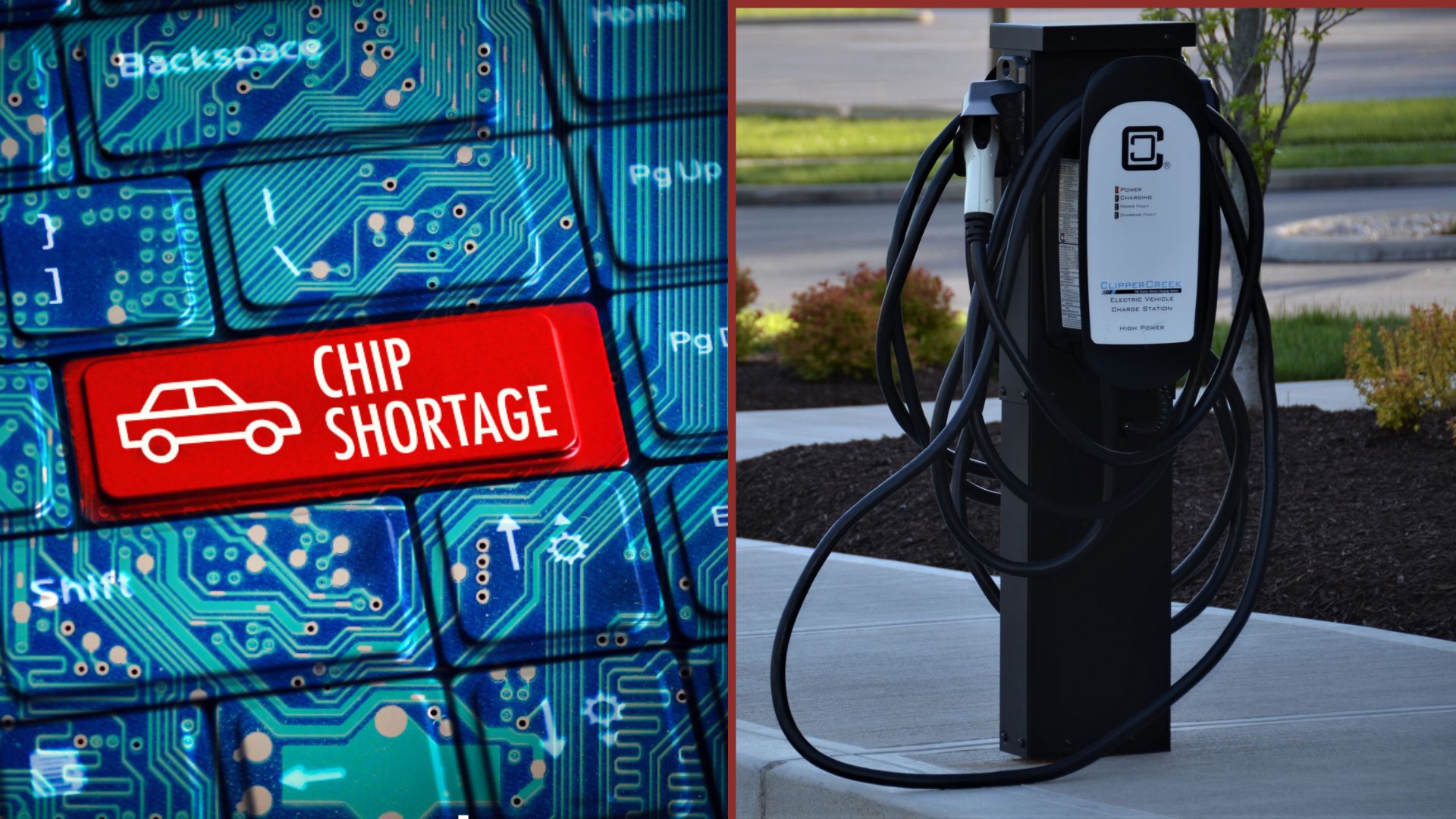

Automakers across the EU have experienced a major decline in new car sales with sales volumes at their lowest rate since 1996. The industry continues to experience issues with the supply of semiconductor chips and consumers are faced with rising inflation.

The global shortage of semiconductor chips has upended the car industry. In 2021, hamstrung by the global microchip shortage, the automotive industry lost more than $200 billion.

Electric medium and heavy-duty truck sales total more than 14,200 in 2021, representing less than 0.3% of the total number of registrations for medium and heavy-duty vehicles worldwide.

China accounted for nearly 90% of those new registrations. It is also important to note a significant decrease in the number of new electric HDV registrations in 2020-2021 compared to 2017-2018.

The electric vehicle market has and continues to be significantly impacted as a result of new vehicle production being extremely reliant on the continuous supply of semiconductors. 2022 has brought on somewhat of the perfect storm with supply chain breakdowns and threats of the highest inflation levels seen in decades affecting most major economies across the globe.

Under these harsh conditions, electric vehicle manufacturers, especially those who plan to produce commercial electric HDTs, should consider strategic investments that will save their capital from depreciating with inflation and allow them to benefit from later demand and a supply revival.

In this regard, the build-out and installation of charging infrastructure is a prospective investment, since the lack of it is one of the primary reasons for the slow growth of the electric commercial vehicle market. Although demand for new commercial trucks is lower than expected at the moment, it is the best time to future-proof with the provision and installation of charging infrastructure.

For EV truck manufacturers and fleet owners, it will allow them to save money and prepare for future development, as commercial routes are well known and won’t change soon. For EV fleet owners that operate out of depots, electrifying their fleet and managing the charging requirements can provide significant savings in refueling costs. It is also possible to extend the life of an electric truck beyond what a fleet owner would consider for a diesel truck. It will also allow them to benefit from second revenue streams, generated from providing charging services to the ever-growing number of personal EV owners on the road.

The coordinated rollout should focus on the most heavily used freight corridors first. Sustainable logistics requires integrated technologies and infrastructure networks. Depot charging, which keeps costs down by charging (often overnight) at slow but sufficient speeds, is the common method used for commercial vehicles, regardless of their duty cycles and application. Providing high-speed charging along major routes may be necessary for fleets with longer but regular routes or predictable operations, such as shuttles, public transit, or school buses.

Fleets with highly variable routes, like urban delivery vans, may also benefit from charging on publicly available chargers in cities, e.g. while drivers take a break. Rapid and ultra-rapid charging on highways will be needed to provide flexibility and autonomy for regional and long-haul electric trucks.

The question is,

What kind of charging infrastructure serves the objective and use case best?

Researchers at Cornell University are developing technology that can charge an electric car in motion. US highways and roads could be embedded with metal plates that charge vehicles through inductive means as they drive over them. These are just some of the evolving technologies still under development.

Meanwhile, fleet owners and electric truck operators struggle to find the technology readily available to satisfy their needs. Well, the answer may lie with the generation of power from clean fuels. Currently, the EU has over 500 LNG stations in operation, with Italy leading the way with 112, Germany with 108, Spain with 79, and France with 60 LNG stations.

The number of liquefied natural gas (LNG) stations is growing at an average of 140% annually. Nearly 900 compressed natural gas (CNG) fueling stations and approximately 60 LNG stations are publicly available in the United States. Hence, a reasonable approach to delivering en-route charging is to develop multifuel EV chargers.

L-Charge’s stationary chargers are perfect for highways and public car parks as they require no connection to an external power grid —the charging units produce power onboard using an internal supply of liquefied natural gas (LNG), hydrogen (H2), or an LNG/hydrogen mixture.

L-Charge also offers a mobile version consisting of a mini-power plant fitted to a light-duty van to deliver an output charge of up to 130 kW. Cost consideration is often key for adoption, and the L-Charge solution offers strong commercial returns, flexibility, and the ability to enhance operational efficiencies. Some fleets, such as those operated by emergency responders, government agencies, and utility companies, may require 24/7 access to charging facilities. They will appreciate a mobile solution, that can roam around the city and be used on-demand.

According to Facts and Factors, a leading research company, the global Electric Vehicle Supply Equipment (EVSE) market is expected to cross USD 210 billion by 2028, growing at a CAGR of 33.2% between 2022 and 2028. Given this projected growth, fleet owners and EV manufacturers could consider investing in clean-fueled EV-charging infrastructure whilst saving money and promoting a seamless transition towards electric freight. Additionally, the proposition provides an opportunity to yield good returns and the chance to own and operate your own charging network.