Table of Contents

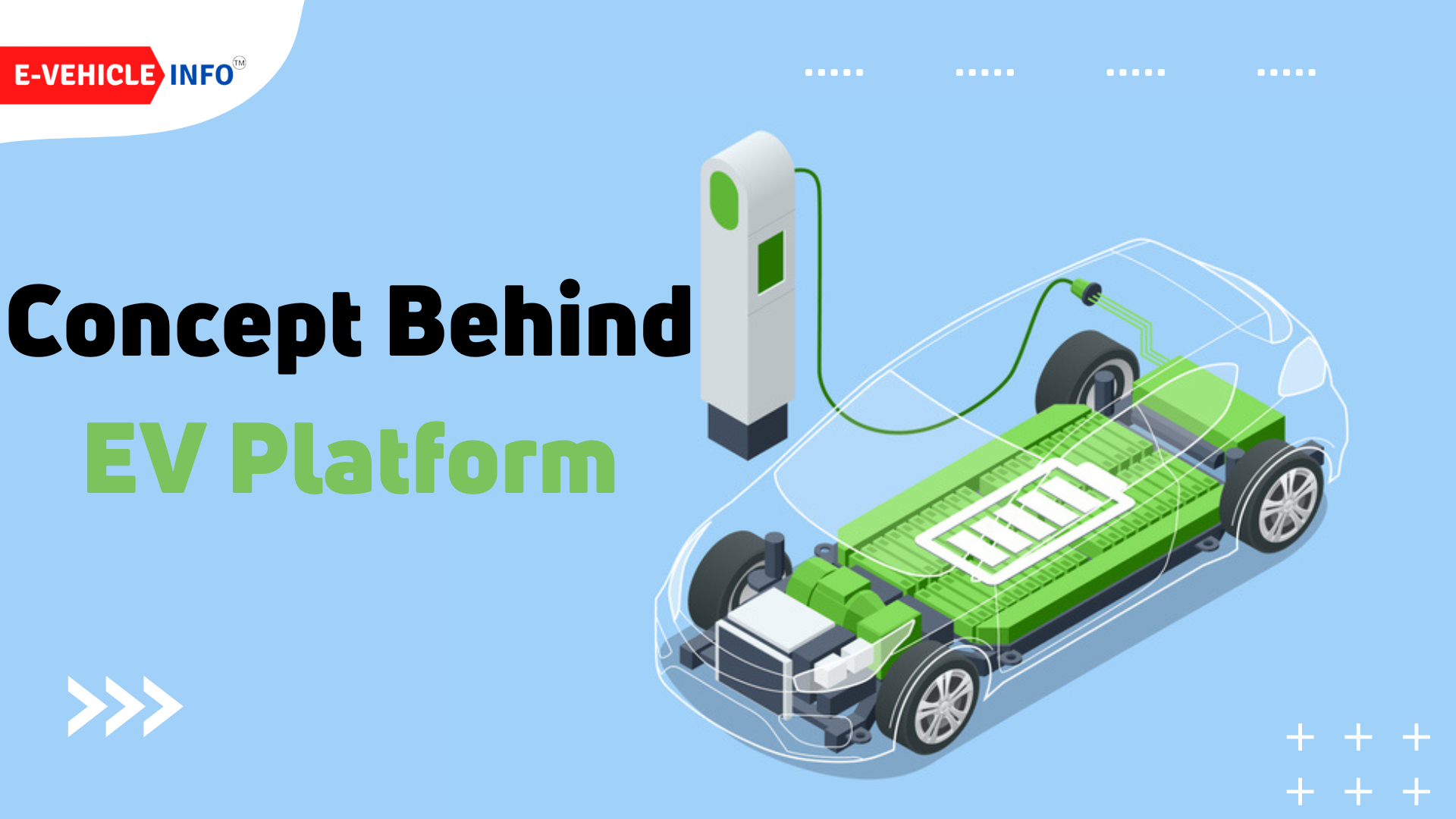

Concept Behind the EV Platform

In the present scenario, the world is going through an industrial transition from fossil fuel-based automobiles to the EV-based industry. Data from a consulting firm confirms that by 2025, a 30% share of vehicles sold will be electric, increasing to 51% by 2030. Consumer preferences for EVs are changing. The proportion of global consumers contemplating purchasing an electric vehicle is increasing. In national surveys conducted in the United States, 10-30% of respondents indicated an interest in purchasing an electric vehicle as their next vehicle. Europe reported a higher proportion of consumers contemplating the purchase of an electric vehicle, between 40-60 %. In contrast, China reported over 70% due to strong government incentives to adopt these vehicles. India’s electric vehicle market is expected to expand at a compounded annual growth rate of 49% between 2021-2030, with the segment’s volumes set to cross annual sales of 17 million by 2030. These trends will depict the continuous improvement in technology to provide more comfortable and long-range electric vehicles with lots of different models required, which can be easily tackled by the EV platform technology discussed in detail in upcoming sections.

What is the EV platform?

A platform is a primary vehicle frame without a power unit (an engine or a motor), a chassis, or a body. The basic structure is based on the concept that this platform will act as a fully autonomous system that consists of many components of an EV, such as battery assembly, wheels, and suspension system. Adjusting the platform’s length and width and changing the number of small batteries in the assembly will be adjusted according to the manufacturer’s requirements.

EV platform enables flexible automobile manufacturing.

If the manufacturer wants to make automobiles independent of size and type, redesigning the chassis is unnecessary. The platform makes changing the wheelbase (the distance between the front and back wheels), the track width (the distance between parallel tyres), and the battery housing easy. For instance, if a car manufacturer is tasked with developing a compact and reasonably priced electric vehicle suitable for urban environments, the wheelbase, track width, and number of battery cells can all be shortened. If it needs to construct a large electric SUV with a long-range, it should make the track width wider, the wheelbase larger, and additional battery cells. For this reason, a manufacturing platform specifically designed for electric vehicles makes the process simpler and more cost-efficient for automobile manufacturers.

Why do we need to redesign the present architecture?

In the past, vehicle manufacturers utilized their old petrol-powered automobile bodies by removing a petrol-powered system with battery assembly. However, in that situation, the old concept generated energy on the front side of the automobile and transported it to the rear wheels, requiring shaft arrangement and reducing passenger room. So many old systems still exist and necessitate the proper operation of the EV on the old chassis system, which will hamper the proper utilization of space that may be expanded within the EVs, which will be the most important driving force for redesigning the present architecture.

EV platform and Indian industry

Tata Motors, the leading manufacturer of electric vehicles in India, has unveiled a fully electric concept vehicle as the next stage in its EV venture. The EV concept will be based on Tata Motors’ first ‘Born Electric’ platform, which will feature a variety of body designs with two- and three-row seating configurations that could be ready to hit the road as early as 2025. The Safari and Harrier EV equivalents could be one of the first products built on the new skateboard.

What role does Platform play in making EV production cost-effective?

A purpose-built EV platform is easier to manufacture and might save up to $600 per vehicle in lower fixed-cost allocation, as stated in a report by McKinsey. Compared to complex facilities that mix ICE-vehicle and EV lines, EV-only plants can save money on capital expenditures because they only need to assemble fewer components.

List of Popular Global EV Platforms in Market

| Sr. No | Company Name | EV Platform Used | Car Models |

| 1 | Hyundai

| Genesis E-GMP Platform | Hyundai/Kia |

| 2 | Tesla

| Skateboard | Tesla Model 3 |

| 3 | Volkswagen | Volkswagen MEB | Škoda Enyaq iV, ID.3 |

| 4 | GM | BEV3 Platform/ GM Ultium Battery | Bolt EUV |

| 5 | Rivian

| R1S Platform | Rivian R1T |

| 6 | Renault/Nissan/Mitsubishi | FWD platform | Nissan Ariya crossover |

| 7 | Toyota / Subaru | e-TNGA | Toyota and Lexus EVs and Subaru Evoltis |

Drawbacks of dedicated EV platform

Dedicated EV platforms require lots of R&D spending and development time, leading to increased vehicle costs and delayed market arrival.

Authors Remark

According to numerous stories, the original concept of this platform technology came from GM but was not adequately employed until Tesla began employing their skateboard in their electric vehicle. This concept reshapes the EV industry by allowing manufacturers to provide a wide range of models on a single platform for a small investment.

Read More:- EV Skateboard Platform: Introduction, Types & Future